- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

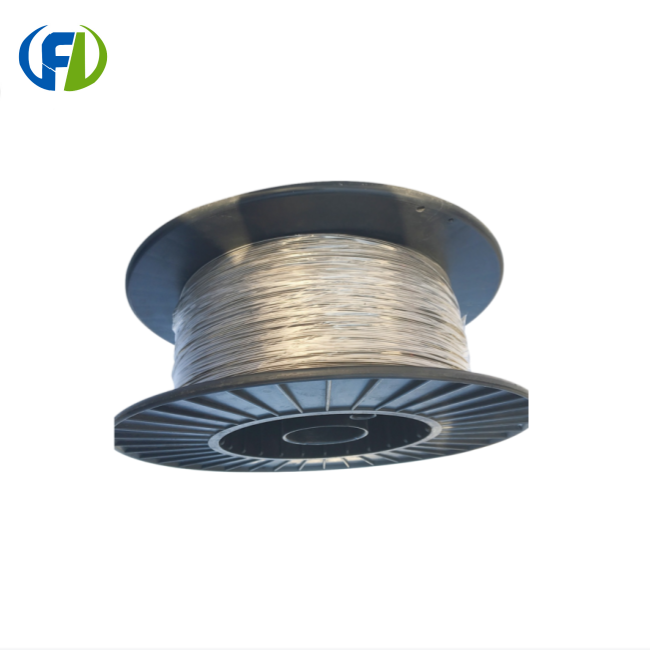

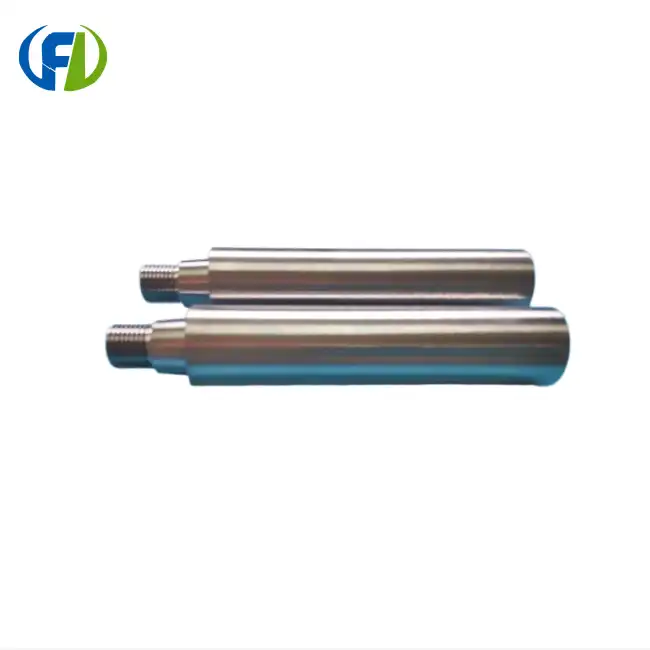

nickel alloy welding rods

Brand: FRL Metal

Material: Nickel-chromium-molybdenum alloys with high strength

Diameter: 2.0–5.0mm

Length: 350mm

Surface: Coated or bare type

Standard: AWS A5.11 / A5.14

Application: Suitable for petrochemical and marine equipment welding.

Certification: ISO9001

Shipping: Fedex, TNT, DHL and EMS

Premium Nickel Alloy Welding Rods - High-Performance Solutions for Critical Applications

When you need reliable joining materials for demanding industrial applications, our premium nickel alloy welding rods deliver exceptional performance and durability. Manufactured by Baoji Freelong New Material Technology Development Co., Ltd., these specialized electrodes are engineered with nickel-chromium-molybdenum compositions to meet the most challenging welding requirements in petrochemical, marine, and high-temperature environments.

|

|

|

Product Introduction

Our nickel-chromium-molybdenum welding electrodes represent the pinnacle of metallurgical engineering. These high-strength rods feature carefully balanced alloy compositions that provide superior mechanical properties and corrosion resistance. Each rod undergoes rigorous quality control to ensure consistent performance in critical applications where standard materials simply won't suffice.

Technical Specifications

- Alloy Type: Nickel-chromium-molybdenum

- Tensile Strength: ≥760 MPa

- Standards Compliance: AWS A5.11 / A5.14

- Available Diameters: 2.0mm - 5.0mm

- Coating Options: Coated and bare type configurations

- Operating Temperature Range: Up to 850°C

- Elongation: Minimum 30%

Key Features and Benefits

Superior Mechanical Properties

Your welding projects demand reliability. Our electrodes deliver exceptional tensile strength and impact resistance that exceeds industry standards.

Excellent Corrosion Resistance

The carefully balanced nickel-chromium composition provides outstanding protection against aggressive chemicals and marine environments.

Consistent Arc Characteristics

Smooth, stable arc performance ensures high-quality welds with minimal spatter and excellent bead appearance.

Extended Service Life

These durable electrodes maintain their properties even under extreme thermal cycling and mechanical stress.

Applications and Industries Served

Petrochemical Industry

- Pressure vessels

- Heat exchangers

- Process piping systems

- Reactor components

Marine Applications

- Offshore platforms

- Shipbuilding components

- Seawater handling systems

- Corrosion-resistant structures

Power Generation

- Steam turbine components

- Boiler applications

- Nuclear facility equipment

Manufacturing Process

At Baoji Freelong, we employ advanced metallurgical techniques to produce these specialized electrodes. Our state-of-the-art facilities ensure precise alloy composition control and consistent coating application. Each batch undergoes comprehensive testing to verify mechanical properties and chemical composition.

Quality Control and Testing

Every electrode lot receives thorough inspection including:

- Chemical composition analysis

- Mechanical property testing

- Radiographic examination

- Surface quality inspection

- Coating integrity verification

Contact Information

Ready to experience the superior performance of our nickel alloy welding rods? Our team stands ready to assist with your specific requirements.

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Contact us today for detailed specifications, pricing information, or to discuss your custom welding electrode needs. We're committed to providing the high-quality materials that make your projects successful.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745896744758.webp)

_1745305348459.webp)