- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

pure tantalum sheet

Brand: FRL Metal

Density: 16.6g/cm³

Purity: 99.95%, 99.99%

Thickness: 0.1~80mm,Width 20~600mm

Length: 50~3000mm

Grade: RO5200,RO5252,RO5255

Standard: ASTM B708

Certification: ISO9001

Shipping: Fedex, TNT, DHL and EMS

Pure Tantalum Sheet - Premium Quality Metal Solutions

Product Introduction

Welcome to Baoji Freelong's premium pure tantalum sheet collection. Our tantalum sheets are engineered for industries demanding exceptional performance and reliability. With a purity level of ≥99.95% meeting ASTM B708 R05200 grade standards, you get consistent quality every time. These sheets feature outstanding corrosion resistance, making them perfect for challenging environments. Whether you need materials for chemical processing or electronics manufacturing, our pure tantalum sheet delivers unmatched durability and performance.

Located in China's Titanium Valley, we bring decades of expertise in refractory metals manufacturing. Our advanced production facilities ensure every sheet meets your exact specifications.

|

|

|

Technical Specifications

Our tantalum sheets come with precise specifications to meet your project requirements:

- Purity: ≥99.95% (ASTM B708 R05200 grade)

- Thickness Range: 0.1mm to 10mm

- Width: Up to 1000mm

- Density: 16.6 g/cm³

- Melting Point: 3017°C

- Surface Finishes: Polished, pickled, or annealed

- Tensile Strength: 200-300 MPa

- Temperature Range: -200°C to 2000°C

Key Features and Benefits

Superior Corrosion Resistance: Your tantalum sheets resist virtually all acids except hydrofluoric acid and concentrated alkalis.

High Temperature Stability: Maintains structural integrity at extreme temperatures up to 2000°C.

Excellent Workability: Easy to machine, weld, and form according to your specific requirements.

Biocompatibility: Perfect for medical applications where human tissue contact is required.

Chemical Inertness: Won't contaminate sensitive processes or react with most chemicals.

Applications and Industries Served

Chemical Processing: Heat exchangers, reaction vessels, and distillation columns benefit from tantalum's exceptional chemical resistance.

Electronics Industry: Capacitors, sputtering targets, and semiconductor components rely on tantalum's unique properties.

Medical Devices: Surgical implants, dental equipment, and prosthetics utilize tantalum's biocompatibility.

Aerospace: High-temperature applications in jet engines and spacecraft components.

Laboratory Equipment: Crucibles, furnace parts, and analytical instruments require tantalum's purity.

Manufacturing Process

We employ advanced metallurgical techniques to produce your tantalum sheets:

Raw Material Selection: Only the highest purity tantalum ingots enter our production line.

Vacuum Melting: Our electron beam melting process ensures uniform composition throughout.

Rolling Process: Precision rolling mills create consistent thickness across the entire sheet.

Heat Treatment: Controlled annealing optimizes mechanical properties and relieves internal stress.

Surface Treatment: Multiple finishing options provide the exact surface quality you need.

Quality Control and Testing

Every sheet undergoes comprehensive testing before shipment:

- Chemical composition analysis using ICP-OES

- Dimensional inspection with precision measuring equipment

- Surface quality evaluation

- Mechanical property testing

- Ultrasonic flaw detection

- Certificate of compliance documentation

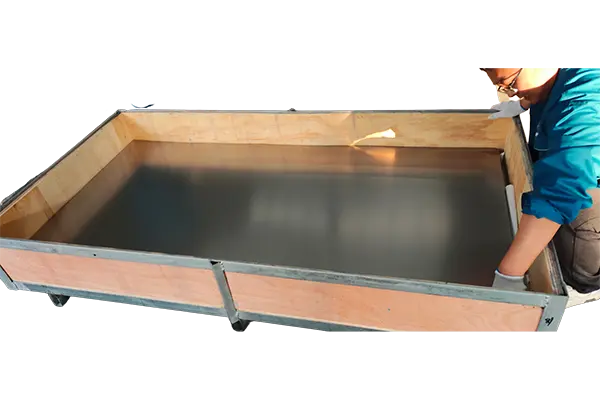

Packaging and Shipping

Your orders receive careful packaging to prevent damage during transit. We use moisture-resistant materials and protective cushioning. Wooden crates provide extra security for larger shipments. Express shipping options ensure fast delivery worldwide. All packages include detailed documentation and handling instructions.

Why Choose Us

Decades of Experience: Based in China's Titanium Valley, we've perfected refractory metal production over many years.

Global Reach: We serve customers across Australia, Korea, Germany, US, UK, Malaysia, Middle East, and Taiwan.

Quality Commitment: We never compromise on quality and stand behind every product we deliver.

Technical Support: Our engineering team provides expert guidance throughout your project.

Competitive Pricing: Direct manufacturer pricing without middleman markups.

OEM & Customization Services

We understand that standard sizes don't always fit your needs. Our OEM services include:

- Custom dimensions and thicknesses

- Specialized surface treatments

- Unique alloy compositions

- Application-specific testing

- Private labeling options

Share your requirements with us, and we'll develop the perfect solution for your application.

Certifications and Compliance

Our manufacturing processes comply with international quality standards. We maintain strict quality management systems and provide full traceability documentation. All products meet relevant industry specifications and regulatory requirements.

FAQs

Q: What's the minimum order quantity for pure tantalum sheet?

A: We accommodate both small prototype orders and large production runs. Contact us for specific quantity requirements.

Q: Can you provide custom dimensions?

A: Absolutely! We specialize in custom sizing to match your exact specifications.

Q: What surface finishes are available?

A: We offer polished, pickled, and annealed finishes. Special treatments are available upon request.

Q: How long is the delivery time?

A: Standard products ship within 2-3 weeks. Custom orders may require 4-6 weeks depending on specifications.

Q: Do you provide material certificates?

A: Yes, every shipment includes complete certification documentation with chemical analysis and test results.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745484304457.webp)

_1744793935501.webp)

_1744958552825.webp)

_1750146004853.webp)