- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

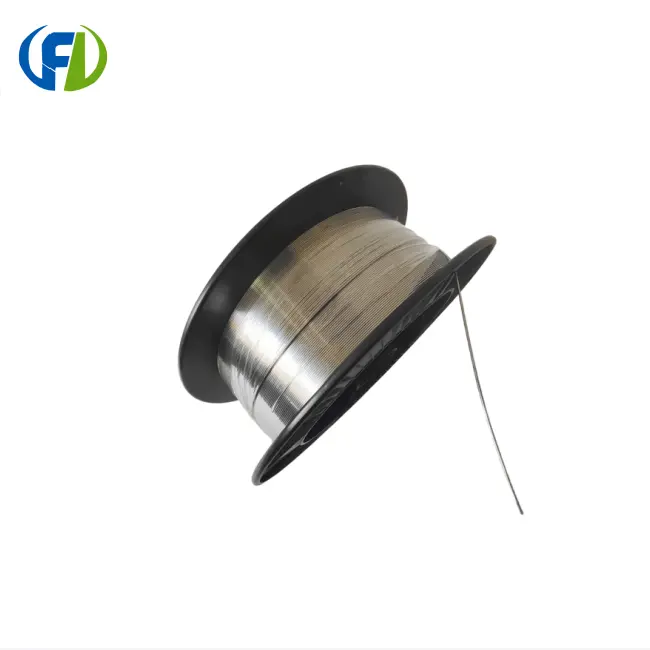

tantalum heater wire

Brand: FRL metal

Density: 16.6 g/cm³

Grade: R05240 Ta–2.5W,

Size: Dia0.3–2mm

Standard:ASTM B 365

Purity: 99.95% minimum

Condition: annealed

Certification: ISO9001

Shipping: Fedex, TNT, DHL and EMS

High-Performance Tantalum Heater Wire - Industrial Heating Solutions

Product Introduction

When you need reliable heating elements for extreme temperature applications, our tantalum heater wire delivers exceptional performance and longevity. Manufactured in China's Titanium Valley, Baoji City, our high-purity tantalum wire offers outstanding thermal properties and corrosion resistance. With diameters ranging from 0.3mm to 2mm and operating temperatures up to 2800°C, you can trust our vacuum-annealed wire for your most demanding heating applications.

|

|

|

Technical Specifications

Our heating wire meets strict industry standards to ensure consistent performance:

- Material: High-purity tantalum (Ta)

- Diameter Range: 0.3mm - 2.0mm

- Maximum Operating Temperature: 2800°C (5072°F)

- Standard Compliance: ASTM B365

- Surface Finish: Vacuum annealed, smooth surface

- Purity Level: 99.95% minimum

- Resistivity: 12.45 µΩ·cm at 20°C

- Density: 16.6 g/cm³

Key Features and Benefits

Extreme Temperature Resistance

Your heating systems benefit from tantalum's exceptional melting point of 3017°C, providing reliable operation well beyond other materials' limits.

Superior Oxidation Resistance

Our vacuum annealing process creates an oxide-resistant surface that extends service life in challenging environments.

Chemical Inertness

You'll experience minimal contamination risks due to tantalum's excellent chemical stability against most acids and corrosive substances.

Consistent Performance

Uniform heating distribution ensures your processes maintain precise temperature control throughout operation cycles.

Long Service Life

The robust construction and material properties significantly reduce replacement frequency, lowering your operational costs.

Applications and Industries Served

Industrial Furnaces

High-temperature furnaces for sintering, annealing, and heat treatment processes rely on our heating elements for consistent results.

Semiconductor Manufacturing

Critical temperature control in wafer processing and crystal growth applications demands the purity and reliability you'll find in our products.

Research Laboratories

Scientific equipment requiring precise heating control benefits from tantalum's stable performance characteristics.

Aerospace Industry

Component testing and manufacturing processes utilize our wire for extreme temperature simulation and material processing.

Medical Device Manufacturing

Sterilization equipment and specialized medical tools depend on reliable heating elements for safety and effectiveness.

Manufacturing Process

Our production follows rigorous quality standards:

Raw Material Selection

We source premium tantalum ingots with verified purity levels to ensure consistent wire properties.

Wire Drawing Process

Multiple drawing stages reduce diameter while maintaining material integrity and surface quality.

Vacuum Annealing

Controlled atmosphere treatment optimizes grain structure and removes internal stresses for enhanced performance.

Quality Inspection

Each batch undergoes comprehensive testing for dimensional accuracy, chemical composition, and mechanical properties.

Quality Control and Testing

Every production batch receives thorough evaluation:

- Chemical composition analysis using spectroscopy

- Dimensional measurements with precision instruments

- Electrical resistivity testing at standard conditions

- Surface quality inspection for defects

- Mechanical property verification including tensile strength

Packaging and Shipping

Your orders receive careful handling to maintain product integrity:

- Individual wire protection with anti-static materials

- Moisture-resistant packaging for long-term storage

- Detailed labeling with specifications and batch numbers

- Secure shipping containers to prevent damage during transit

- Complete documentation including certificates of analysis

Why Choose Us

Manufacturing Expertise

Located in China's Titanium Valley, Baoji Freelong New Material Technology brings decades of experience in refractory metal processing.

Global Partnerships

We maintain trusted relationships with clients across Australia, Korea, Germany, the United States, United Kingdom, Malaysia, and the Middle East.

Quality Commitment

Our company takes full responsibility for quality and service, ensuring your requirements are met without compromise.

Technical Support

You receive comprehensive assistance from material selection through application optimization.

FAQs

Q: What's the minimum order quantity?

A: We accommodate various order sizes, from small research quantities to large industrial requirements. Contact us for specific minimums.

Q: How do you ensure consistent quality across batches?

A: Our quality control system includes incoming material inspection, in-process monitoring, and final product testing with documented results.

Q: Can you provide technical support for application development?

A: Yes, our technical team offers guidance on material selection, installation procedures, and performance optimization.

Q: What's the typical lead time for orders?

A: Standard products usually ship within 2-3 weeks, while custom specifications may require additional time for processing.

Q: Do you offer sample quantities for testing?

A: We provide samples to qualified customers for evaluation purposes before placing larger orders.

Contact Information

Ready to enhance your heating applications with premium tantalum heater wire? Our technical team stands ready to assist with your specific requirements.

Email: jenny@bjfreelong.com

WhatsApp: +86 135 7119 0943

Connect with us today to discuss your heating element needs and discover how our advanced materials can improve your process performance and reliability.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1756088080569.png)

_1744959568232.webp)

_1745890919038.webp)