- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Gr1 Gr2 Titanium Foil 0.1mm

Brand: FRL Metal

Grade: Gr1 Gr2

Density: 4.51g/cm3

Thickness: 0.1mm

Width: <600mm

Surface: Polished

Standard: ASTM B265,ASME SB265,ASTM F136/67, AMS 4911,AMS 4905, AMS 4907, MIL-T-9046

Certification:ISO9001

Delivery Time:5~7days

Payment Terms:T/T

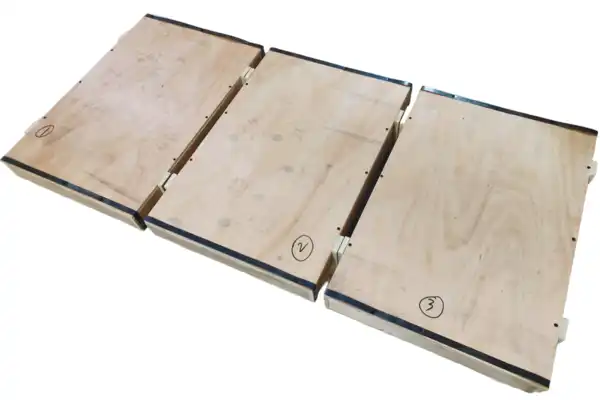

Packaging Details:Plywood case

Description of Gr1 Gr2 Titanium Foil 0.1mm

High Purity Titanium Foil, Titanium Coil Titanium Foil Titanium Coil and Tape Titanium has a steel-like appearance and a silver-gray light translation. It is a transition metal, and it has been considered a rare metal for some time in the past. Titanium is not a rare metal. Titanium accounts for about 0.42% of the total weight in the earth's crust, which is 16 times the total of copper, nickel, lead and zinc. There are more than 70 kinds of minerals containing titanium. Titanium has high strength, low density, high hardness, high melting point and strong corrosion resistance; high-purity titanium has good plasticity, but becomes brittle and hard when impurities exist.

Where is Gr1 Gr2 Titanium Foil 0.1mm mainly used?

It is mainly used for the tweeter membrane of loudspeakers and speakers. Titanium foil is used for high fidelity, and the sound is clear and bright. Titanium foil material can also be used in various accessories, for implants on bones, etc.

Titanium foil is a titanium plate, strip, roll or sheet with a thickness of 0.1 mm or less. Titanium foil has different uses according to different specifications. Sound film, medical, fine chemicals, accessories, etc., are now more and more from industry to civilian use.

Gr1 Gr2 Titanium Foil 0.1mm picture display

|

|

|

Gr1 Gr2 titanium foil 0.1mm Production method

Cold rolled:

The most popular flat roll belt rolling technique is used to manufacture titanium foil because of its high production, scale, and productivity. Basically, for production, use a cold rolling mill with six or twenty levels.

Heat treatment:

Titanium foil can be heated using two common techniques: vacuum annealing and continuous online protection annealing.A novel technique called continuous online protective annealing of titanium strip foil is vacuum annealing, which involves heating up rolled or sheet titanium foil in a vacuum furnace.introduced in recent years, which is what our company adopts. Compared with vacuum Annealing has higher production efficiency, and has a higher improvement in product quality, and has a good guarantee for product quality and mechanical properties of titanium foil

corrosion resistance:

Titanium is resistant to corrosion well and is unaffected by air and water. Under normal temperature, it will not be corroded by hydrochloric acid below 7%, sulfuric acid below 5%, nitric acid, aqua regia or dilute alkali solution; only hydrofluoric acid, concentrated hydrochloric acid, concentrated sulfuric acid, etc. can act on it.

Introduction of Titanium

Titanium has plasticity, the elongation rate of high-purity titanium can reach 50-60%, and the section shrinkage rate can reach 70-80%, but the shrinkage strength is low (that is, the strength generated when shrinking). The presence of impurities in titanium has a considerable impact on its mechanical characteristics, particularly interstitial impurities (oxygen, nitrogen, and carbon), which can dramatically increase titanium's strength and decrease its flexibility. When used as a structural material, titanium has excellent mechanical qualities that are produced by carefully regulating the suitable impurity content and alloying components.

Titanium metal has strong anti-damping performance. After being subjected to mechanical vibration and electrical vibration, its own vibration attenuation time is the longest compared with steel and copper metals. Using this property of titanium, titanium foil can be used as a tuning fork, a vibration element of a medical ultrasonic mill and a vibration film of an advanced audio speaker.

FAQ

1. Are you a factory or a trading company?

Our factory has 10 years of production experience.

2. Can you provide samples? MOQ?

Yes, we can provide you with free samples. MOQ: 5kg.

3. Do you accept customization?

Yes, we can process according to your unit weight or drawing.

4. Do you check the finished product?

Yes, every product will be checked by our QC before shipment.

5. How much is the shipping fee?

Mainly depends on weight, volume, package size and destination port.

6. What is your delivery time?

In stock, 1-2 days, if not, according to your quantity.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1756351641281.png)

_1745737301913.webp)

_1745487678013.webp)

_1745219704984.webp)