- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

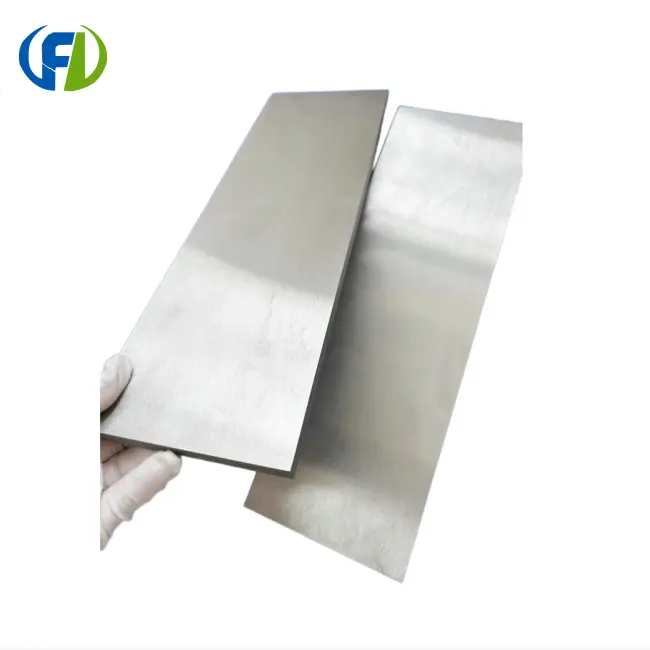

grade 7 titanium plate

Brand: FRL metal

Density: 4.51g/cm³

Grade: Gr7 (Ti-0.2Pd)

Standard: ASTM B265 / ASME SB-265

Thickness: 0.5–50 mm Or As Per Customer's Request

Advantages: high strength and corrosion resistance

Certification: ISO9001

Delivery time: 7-15 days

Packaging Details: Plywood case

Grade 7 Titanium Plate - Superior Corrosion Resistance for Industrial Excellence

Product Introduction

When you need the ultimate combination of strength and corrosion resistance, our grade 7 titanium plate delivers exceptional performance for your most demanding applications. This premium titanium alloy, designated as Ti-0.2Pd (Grade 7), incorporates palladium to provide unmatched resistance to aggressive chemical environments.

Our plates are manufactured to ASTM B265 Grade 7 standards, ensuring you receive consistent quality and reliability. With thickness options ranging from 1mm to 50mm, these plates meet diverse industrial requirements while maintaining superior mechanical properties and chemical stability.

|

|

|

Technical Specifications

| Property | Value |

|---|---|

| Alloy Designation | Ti-0.2Pd (Grade 7) |

| Standard | ASTM B265 Grade 7 |

| Thickness Range | 1-50 mm |

| Density | 4.51 g/cm³ |

| Tensile Strength | ≥345 MPa |

| Yield Strength | ≥275 MPa |

| Elongation | ≥20% |

| Palladium Content | 0.12-0.25% |

Key Features and Benefits

Enhanced Corrosion Resistance: The palladium addition provides exceptional resistance to reducing acids and crevice corrosion, making it ideal for harsh chemical environments.

Superior Strength-to-Weight Ratio: You get outstanding structural integrity with significantly lower weight compared to steel alternatives.

Excellent Weldability: Easy to fabricate and weld, allowing you to create complex assemblies without compromising material properties.

Long Service Life: Exceptional durability reduces maintenance costs and extends equipment lifespan in demanding applications.

Biocompatibility: Safe for medical and pharmaceutical applications where material purity is critical.

Applications and Industries Served

Our titanium plates serve various industries where reliability matters most:

- Chemical Processing: Reactors, heat exchangers, and piping systems

- Marine Engineering: Offshore platforms, desalination plants, and submarine components

- Pharmaceutical Industry: Process equipment requiring high purity standards

- Power Generation: Condenser tubes and cooling systems

- Aerospace: Structural components requiring high strength and corrosion resistance

Manufacturing Process

We employ advanced manufacturing techniques to ensure consistent quality:

- Raw Material Selection: High-purity titanium sponge and certified palladium

- Vacuum Arc Remelting: Creates homogeneous alloy structure

- Hot Rolling: Achieves precise thickness and mechanical properties

- Heat Treatment: Optimizes microstructure for maximum performance

- Precision Cutting: Custom dimensions to meet your specifications

Quality Control and Testing

Every plate undergoes rigorous testing to ensure it meets your requirements:

- Chemical composition analysis using X-ray fluorescence

- Mechanical property testing including tensile and hardness tests

- Ultrasonic inspection for internal defect detection

- Surface quality examination

- Dimensional verification to tolerances

Packaging and Shipping

Your plates are carefully packaged to prevent damage during transit:

- Individual protective wrapping prevents surface contamination

- Wooden crates with shock-absorbing materials for international shipping

- Clear labeling with material certificates and traceability information

- Expedited shipping options available for urgent requirements

Why Choose Us

Location Advantage: Based in Baoji City, China's Titanium Valley, we have direct access to premium raw materials and specialized manufacturing expertise.

Global Experience: We serve customers across Australia, Korea, Germany, the US, UK, Malaysia, and the Middle East, understanding diverse market requirements.

Quality Commitment: We never compromise on quality. Our responsibility is delivering products that meet or exceed your expectations.

Technical Support: Our experienced team provides comprehensive technical assistance from material selection to application guidance.

OEM & Customization Services

We understand that standard specifications don't always meet your unique requirements. Our customization services include:

- Custom thickness and dimensions

- Special surface treatments

- Modified chemical compositions within grade specifications

- Small batch production for prototyping

- Technical consultation for application-specific solutions

Whether you need standard plates or specialized configurations, our grade 7 titanium plate solutions are tailored to your exact needs.

Certifications and Compliance

Our manufacturing processes comply with international quality standards, ensuring you receive materials that meet global specifications. We maintain comprehensive documentation and traceability for all products.

FAQs

Q: What makes Grade 7 titanium different from other grades?

A: The palladium addition provides superior corrosion resistance, especially in reducing acid environments where other grades may fail.

Q: Can you provide custom sizes?

A: Yes, we offer custom cutting and sizing services to meet your specific dimensional requirements.

Q: What's the typical lead time for orders?

A: Standard sizes are typically available within 2-3 weeks, while custom orders may require 4-6 weeks depending on specifications.

Q: Do you provide material certificates?

A: Yes, we provide comprehensive material test reports and certificates with every shipment.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745830219482.webp)

_1769676035515.png)

_1745889999950.webp)

_1745736881103.webp)