- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

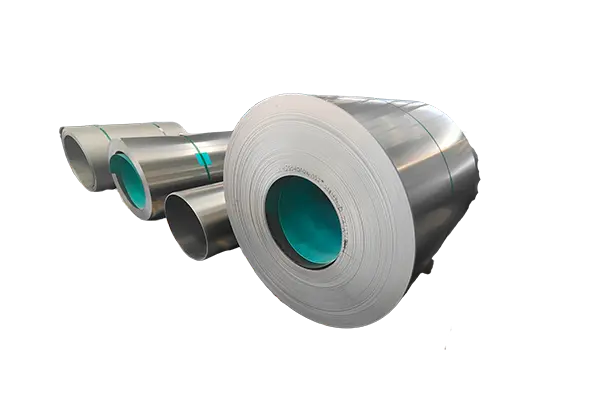

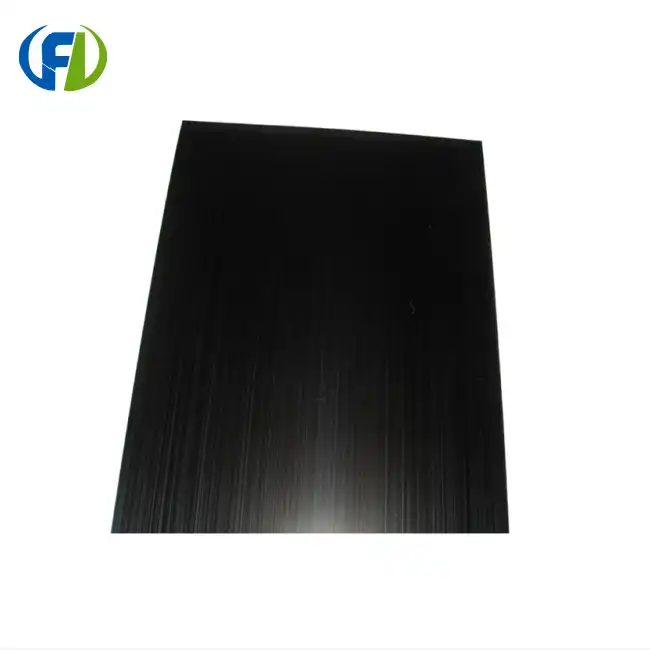

titanium sheet 0.5 mm

Brand: FRL metal

Density: 4.51g/cm³

Grade: Gr1 / Gr2 / Gr3 / Gr4 /TA1 / TA2 /TA3 / TC4 / TC11 / TC21

Standard: ASTM B265,ASTM B551,ASTM B352

Thickness: 0.5mm 0.6mm 1mm 2mm 3mm 4mm Or As Per Customer's Request

Processing technology: cold rolling/hot rolling

Advantages: high strength and corrosion resistance

Certification: ISO9001

Delivery time: 3-7 days

Packaging Details: Plywood case

Technical Specifications

Our precision-manufactured thin titanium sheets feature carefully controlled specifications:

- Thickness: 0.5 mm with ±0.03 mm tolerance

- Grade Options: TA1(Gr1) TA2 (Gr2)TA3(Gr3) TC4(Gr5 Ti-6Al-4V alloy)

- Standard Width: 1000 mm /1220mm(custom widths available)

- Surface Finish: Bright annealed for superior appearance

- Length: Available in various lengths to meet your project needs

- Chemical Composition: Meets ASTM B265 standards

|

|

|

Key Features and Benefits

Exceptional Corrosion Resistance

Your projects benefit from titanium's natural resistance to harsh chemicals, saltwater, and extreme environments. This ensures long-lasting performance in challenging conditions.

Lightweight Yet Strong

With a strength-to-weight ratio superior to steel, our sheets provide structural integrity while minimizing overall weight for your applications.

Biocompatibility

Perfect for medical device manufacturing, our titanium meets strict biocompatibility standards for safe human contact.

Temperature Stability

Maintains mechanical properties across wide temperature ranges, from cryogenic to elevated temperatures.

Applications and Industries Served

Aerospace Industry

- Aircraft skin panels and structural components

- Engine components requiring heat resistance

- Spacecraft thermal protection systems

Medical Sector

- Surgical instrument manufacturing

- Implantable device components

- Diagnostic equipment housings

Chemical Processing

- Heat exchanger plates

- Reactor vessel linings

- Corrosion-resistant piping systems

Marine Applications

- Boat hulls and superstructures

- Offshore platform components

- Desalination equipment

Manufacturing Process

Our state-of-the-art facility employs advanced rolling techniques to achieve precise 0.5 mm thickness. The process begins with high-purity titanium ingots, which undergo controlled hot rolling followed by cold rolling to achieve final dimensions.

Heat treatment and bright annealing ensure optimal mechanical properties and surface finish. Every step follows strict quality protocols to guarantee consistent results across production runs.

Quality Control and Testing

We implement comprehensive testing procedures including:

- Dimensional verification using precision measuring equipment

- Chemical composition analysis via spectrometry

- Mechanical property testing for tensile strength and elongation

- Surface quality inspection for defects or irregularities

- Non-destructive testing when required

Each batch receives detailed certification documenting compliance with international standards.

Packaging and Shipping

Your titanium sheet 0.5 mm orders receive careful packaging to prevent damage during transit. We use protective interleaving materials and sturdy wooden crates for international shipping.

Our logistics team coordinates with reliable freight partners to ensure timely delivery to your location. Tracking information keeps you informed throughout the shipping process.

Why Choose Us

Location Advantage

Based in Baoji City, China's Titanium Valley, we have direct access to premium raw materials and specialized manufacturing expertise.

Global Reach

We've built strong relationships with clients across Australia, Korea, Germany, the United States, United Kingdom, Malaysia, and the Middle East.

Quality Commitment

Quality and service form the foundation of our business. We never compromise on material standards or customer satisfaction.

Technical Expertise

Our experienced team understands the unique requirements of working with ultra-thin titanium sheets.

OEM & Customization Services

We understand that your applications may require specific dimensions or properties. Our OEM services include:

- Custom width and length cutting

- Specialized surface treatments

- Alternative grade specifications

- Unique packaging requirements

Contact our technical team to discuss your specific needs for modified titanium sheet 0.5 mm products.

Certifications and Compliance

Our manufacturing processes and quality systems meet international standards. We maintain certifications for aerospace and medical applications where applicable. All products comply with ASTM specifications and relevant international standards.

Frequently Asked Questions

Q: What's the minimum order quantity?

A: We accommodate both small prototype orders and large production runs based on your needs.

Q: Can you provide material certificates?

A: Yes, we provide complete mill test certificates with chemical and mechanical property data.

Q: What lead times should I expect?

A: Standard products typically ship within 3-7 days, while custom specifications may require additional time.

Q: Do you offer technical support?

A: Our experienced team provides comprehensive technical assistance for material selection and application guidance.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1767856385773.png)

_1745733702008.webp)

_1745546029429.webp)