- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

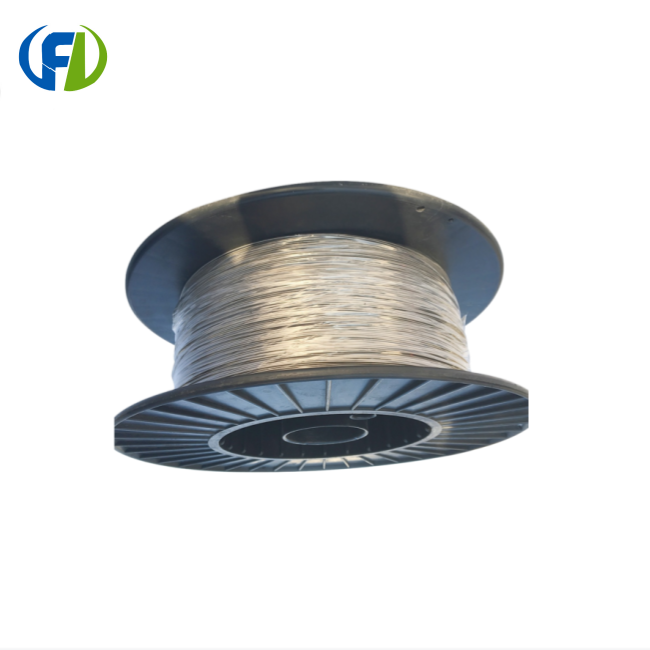

Gr12 Titanium Pipe

Brand: FRL metal

Density: 4.51g/cm³

Grade: TA10 Gr12

Standard: ASTM B337、ASTM B338、ASTM B861

Size: Customizable

Surface: polished/pickling

Certification: ISO9001

Delivery time: 7-15 days Packaging Details: Plywood case

The manufacturing process of Gr12 Titanium Pipe includes the following main steps:

1. Melting and casting: Melting into ingots through vacuum consumable arc furnace, and then forging or rolling into bars or plates.

2. Pipe forming: Processing bars or plates into pipes through extrusion or cold rolling.

3. Heat treatment: Heat treatment of the formed pipe to eliminate internal stress and improve its mechanical properties.

4. Surface treatment: Surface pickling, passivation or coating treatment to enhance its corrosion resistance.

Picture display

|

|

|

Gr12 Titanium Pipe Standards and Specifications

The specifications and standards of Gr12 Titanium Pipe are generally based on national or international standards, such as GB/T 3624, ASTM B861, etc. The specific specifications can be customized according to application requirements.

Gr12 Titanium Pipe Quality Control

Quality control includes chemical composition analysis, mechanical property testing (such as tensile, compression, bending tests), non-destructive testing (such as ultrasonic testing, X-ray testing), etc., to ensure that the product meets standard requirements and application requirements.

FAQ

1:Do you have the titanium Wire in-stock?

Yes, we have a lot of size of grade 2 grade 5 grade 9 titanium wire in-stock, i can show you in any time.

2:Did you have a rich experience in production about titanium alloy?

We have 10 years experience to produce and develop the content of ingredients.

3:How can I trust your production?

We can supply The Third Test Report.

4: How about the delivery time?

If no stock, the delivery time need 7-15 work days.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1770261713682.png)

_1768291065706.png)

_1745725655452.webp)