- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Gr5 Ti6al4v Pipe

Brand: FRL metal

Density: 4.51g/cm

Grade: Gr5, TC4

Standard: ASTM B861

Advantages: High strength and corrosion resistance

Certification: ISO9001

Delivery time: 7-15 days

Packaging Details: Plywood case

Gr5 Ti6al4v Pipe Specifications

Grade:Gr5,

OD:1mm-300mm

WT:0.3mm-15.24mm

L:with in 18Meters

Standard:ASTM B337,ASTM B338,ASTM B861

Surface Treatment:polished or according to customer's requirement.

|

Production Name |

Gr5 titanium tube |

|

Grade |

Gr5 |

|

Standard |

ASTM B337,ASTM B338,ASTM B861 |

|

Application |

heat exchanger,condensor . environmental protection equipment cooling pipe titanium heat pipe Electroplating equipment ring precision instruments |

|

Feature |

High corrosion resistance, low density, good thermal stability |

|

Packing |

Wooden case as outside,plastic bag as inside,or standard export packaging |

|

Payment terms |

T/T, Paypal, West Union. |

|

Delivery time |

7—30 days (according to the quantity and process of the product) |

|

Quality And test |

Strict test is indispensible,because we must insure our clients get the best product |

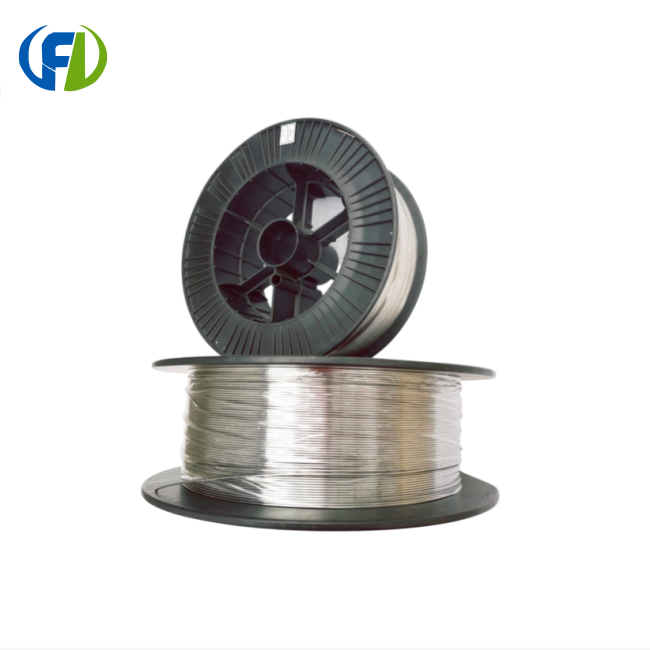

Gr5 Ti6al4v Pipe picture display

|

|

|

Gr5 Ti6al4v Pipe chemical composition

|

N |

C |

H |

Fe |

O |

Al |

V |

Pd |

Mo |

Ni |

Ti |

|

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

bal |

Seamless titanium tube range

OD:1.0mm-300mm

WT:0.3mm-120mm

Length: <18000mm

Material:Gr1, Gr2, Gr3, Gr4 Gr5, Gr7, Gr9, Gr11, Gr12, Gr16,Gr17, Gr23

Welded titanium tube range

OD:6mm-219mm

WT:0.5mm-10mm

Length:<18000mm Material: Gr1,Gr2,Gr3,Gr5,Gr9

Allowable Deviation of Outer Diameter (mm)

| Outer Diameter | Allowable Deviation | Outer Diameter | Allowable Deviation |

| 3~10 | ±0.15 | >50~80 | ±0.65 |

| >10~30 | ±0.30 | >80~100 | ±0.75 |

| >30~50 | ±0.50 | >100 | ±0.85 |

Curvature of Titanium Tube

|

Outer Diameter (mm) |

Curvature (mm/m, not more than) |

|

≤30 |

3 |

|

>30~110 |

4 |

Mechanical property of the titanium tube in the room temperature

|

Model Number |

Status |

Tensile Strength /Mpa |

Stretch of Specified Residual Force/Mpa |

Elongation/% (L0=50mm) |

|

GR1 |

M |

280-420 |

more than 170 |

more than 24 |

|

GR2 |

370-530 |

more than 250 |

more than 20 |

|

|

GR3 |

440-620 |

more than 320 |

more than 18 |

|

|

GR7 |

370-530 |

more than 250 |

more than 20 |

|

|

GR12 |

more than 440 |

__ |

more than 18 |

Common problems in the construction of Gr5 Ti6al4v pipe

5.In the construction of Gr5 Ti6al4v pipe, some small holes such as condensation, drainage, and instrument source components are often encountered, and it is difficult to make holes with conventional methods. Before the Gr5 Ti6al4v pipe is welded, the size of the hole and the detailed and accurate position of the hole are drawn on the corresponding titanium pipe. Use a lathe to drill many small holes along the centerline of the edge of the hole, the denser the better. After all the holes are drilled, use a copper hammer to lightly hit the center arc plate of the hole to separate it, and then use a fine-tooth round file and other special tools to process the hole to meet the requirements. 3 Titanium tube welding process. Impurities such as oil stains and oxide films on the surface of titanium pipes will cause damage to welding. They must be cleaned before welding. All welding surfaces and the surface of the base material on each side of the weldment should be removed with a non-inducing wire brush within the range of at least 50 nrn. The surface of the titanium tube of the layer needs to remove the oxide film, and then the base material is cleaned with acetone. The welding wire must also be cleaned in the same way. The processed weldment and welding wire should be assembled and welded immediately. If it is placed for more than 2 hours, the above process must be cleaned up again. At the same time, the operator must wear clean gloves during the welding process. The welding environment should be clean and the wind direction should be appropriate to reduce the dust in the air to protect the sides of the groove and the welding wire.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail: jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1744774846978.webp)

_1745718988133.webp)

_1745572411472.webp)