- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Welded Pipe

Brand: FRL metal

Density: 4.51g/cm³

Grade: GR1,GR2,GR5,GR7,GR9,GR12

Standard: ASTM B338/ASME SB338、ASTM B862/ASME SB862

Wall Thickness: 0.5-8.0mm

Advantages: high strength and corrosion resistance

Certification: ISO9001

Delivery time: 7-15 days

Packaging Details: Plywood case

In what fields are titanium welded pipes widely used?

1. Chemical industry: Titanium welded pipes have very strong corrosion resistance and can withstand high concentrations of acidic and alkaline substances. Therefore, they are often used in the chemical industry to manufacture reactors, heat exchangers, storage tanks, pipelines and other equipment.

2. Ocean engineering field: Titanium welded pipe has good seawater corrosion resistance, so it is often used in shipbuilding, submarine pipelines, seawater desalination equipment, etc. in the field of ocean engineering.

3. Biomedical field: Titanium welded pipe has good biocompatibility and will not cause any toxicity to the human body, so it is often used in the biomedical field to manufacture artificial joints, dental dentures, surgical instruments, etc.

4. Aerospace field: Titanium welded pipe has the characteristics of high strength and low density, so it is often used in the aerospace field to manufacture aero engines, aircraft structural parts, satellites, etc.

5. Oil and gas field: Titanium welded pipe has very strong corrosion resistance and high temperature resistance, so it is often used in the manufacture of oil well drilling tools, downhole pipelines, and oil refining equipment in the oil and gas field.

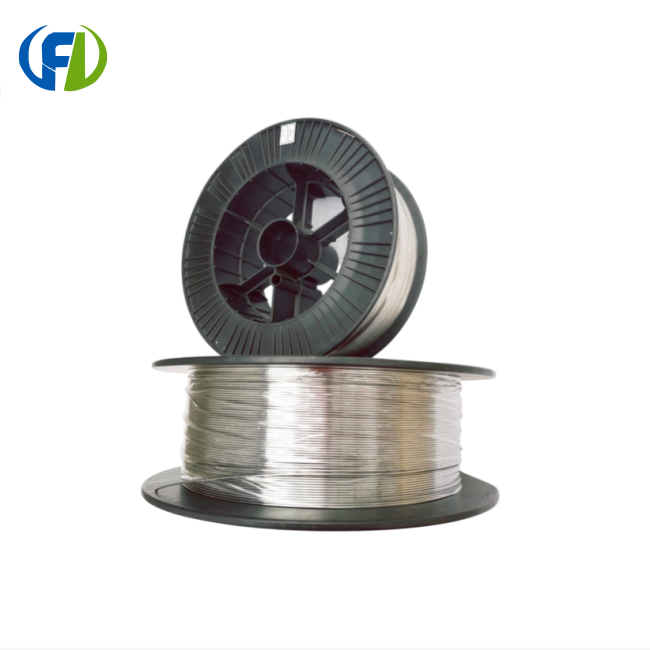

Titanium Welded Pipe Picture display

|

|

|

Comparison of brands from different countries

| US brand number | China grade | Main alloy components (balance: titanium) |

| Gr1 | TA1 | Pure titanium |

| Gr2 | TA2 | Pure titanium |

| Gr3 | TA3 | Pure titanium |

| Gr4 | TA4 | Pure titanium |

| Gr5 | TC4 | 6%Al+4%V |

| Gr6 | TA7 | 5%Al+2.5%Sn |

| Gr7 | TA9 | 0.12~0.25%Pb |

| Gr9 | TA18 | 3%Al+2.5%V |

| Gr11 | TA9-1 | 0.12~0.25%Pb |

| Gr12 | TA10 | 0.3%Mo+0.8%Ni |

| Gr13 | 0.5%Ni+0.05%Ru | |

| Gr14 | 0.5%Ni+0.05%Ru | |

| Gr15 | 0.5%Ni+0.05%Ru | |

| Gr16 | 0.04~0.08%Pb | |

| Gr17 | TA8-1 | 0.04~0.08%Pb |

| Gr18 | TA25 | 3%Al+2.5%V+0.04~0.08%Pb |

| Gr19 | TB9 | 3%Al+8%V+6%Cr+4%Zr+4%Mo |

| Gr20 | TB9 | 3%Al+8%V+6%Cr+4%Zr+4%Mo+0.04~0.08Pb |

| Gr21 | TB8 | 15%Mo+3%Al+2.7%Nb+0.25%Si |

| Gr23 | TC4 ELI | 6%Al+4%V ELI |

| Gr24 | TC22 | 6%Av+4%V+0.04~0.08Pb |

The parameters of titanium welded pipe mainly include the following aspects:

1. Outer diameter (OD): The outer diameter of the titanium welded pipe refers to the outer diameter of the pipe, usually expressed in millimeters (mm). According to different application fields and requirements, the outer diameter of titanium welded pipes will be available in different sizes.

2. Wall thickness (WT): The wall thickness of titanium welded pipe refers to the thickness of the pipe wall, usually expressed in millimeters (mm). The choice of wall thickness depends on the specific application requirements, taking into account factors such as the working environment and the required strength.

3. Length (Length): The length of the titanium welded pipe refers to the overall length of the pipe, usually expressed in meters (m). Titanium welded pipes can be customized in length according to specific needs, and there are also some commonly used standard lengths to choose from.

4. Material/grade: Titanium welded pipe is usually made of titanium alloy, and the specific grade will vary according to the alloy composition and performance requirements. Common grades of titanium alloys include Ti-6Al-4V, Ti-3Al-2.5V, etc., which have different characteristics and scope of application.

5. Specifications and standards: The manufacture and quality control of titanium welded pipes usually follow certain specifications and standards, such as ASTM (American Society for Testing and Materials) and ASME (American Society of Mechanical Engineers). Specification standards include requirements for size, chemical composition, physical properties, welding requirements, etc.

6. Surface treatment: The surface treatment of the titanium welded pipe can be selected according to the needs. The common treatment methods include pickling, polishing, sandblasting, etc. to improve the surface quality and aesthetics of the pipe.

FAQ

1. Any discount?

A: The prices we quote are all wholesale prices in the first place. Meanwhile, our best price will be offered according to your order quantity, so please specify your purchase quantity when you inquire. The more your order, the better discounts we will offer.

2. Are you a manufacturer?

A: Yes. As a manufacturer with 15 years of experience, we've gained adequate expertise and proficiency.We also have our own foreign trade sales team,Relying on our own factory, we offer you our best quality products as we have fully equipped the Product Department and QC Department.

3. How do I know if my products are delivered?

A: We will inform you Tracking No. for your reference or you can contact us anytime for shipment information.

4. How about the quality of the products?

A: We guarantee strict control over every detail of the products. Each product is carefully inspected and tested before delivery.

5.What about payment terms?

A: T/T, L/C, Western Union Paypal are accepted.

6. How about the delivery time?

A: Usually within 7-15 days via express delivery. But it depends on your order quantity as well.

7. If you have additional questions, please feel free to contact us.

Our advantage

1. Equipment Advantages

There are planing machine, milling machine, annealing furnace, laser cutting machine, bending machine, leveling machine, punching machine and forging hammer, etc.

2. The Product Advantages

Large quantity of spot stock, can provide samples, can be processed and customized according to the drawings.

3. Price Advantages

Source factory production, no middlemen, factory price delivery.

4. Quality Advantages

Provide material report, if customer needs, can provide third party test report.

5.And Service Advantages

Professional customer service throughout the service for you, if you encounter product quality problems can be returned free of charge.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail: jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745545705581.webp)

_1745547690653.webp)

_1767950289006.png)