- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

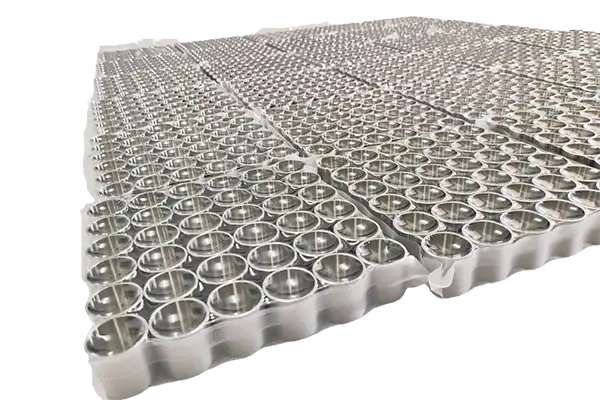

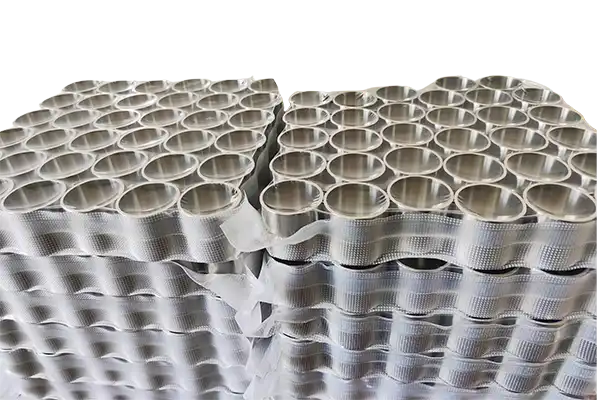

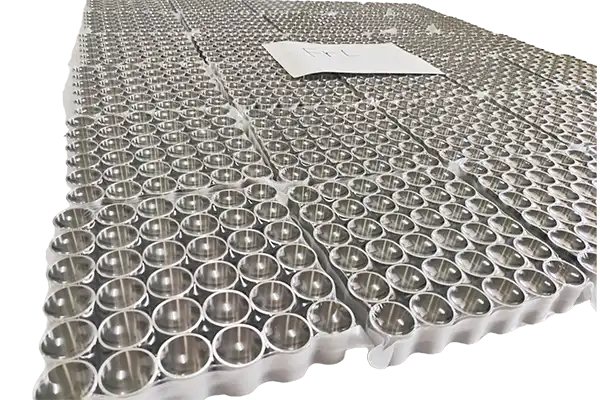

Zirconium Crucible Ø65×65mm For Thermal Processing

Brand: FRL Metal

Surface: polished surface

Density: 6.51g/cm3

Minimum Order Quantity:1pc

Sample: available

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Zirconium Crucible Ø65×65mm For Thermal Processing: Precision-Engineered for High-Temperature Applications

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of high-quality 【Zirconium Crucible Ø65×65mm For Thermal Processing】. Our advanced manufacturing capabilities, strict quality control, and deep industry expertise make us the preferred choice for professionals in materials research, aerospace, and semiconductor industries. With our 【Zirconium Crucible Ø65×65mm For Thermal Processing】, you can confidently tackle your most demanding high-temperature applications.

Zirconium Crucible Ø65×65mm For Thermal Processing picture display

|

|

|

Product Introduction

Our 【Zirconium Crucible Ø65×65mm For Thermal Processing】 is a precision-engineered thermal processing solution designed for extreme temperature environments. Crafted from high-purity zirconium (>99.9% Zr), this crucible offers exceptional resistance to thermal shock, corrosion, and chemical reactions. Its compact dimensions of Ø65×65mm make it ideal for controlled laboratory experiments and industrial processes requiring precise thermal control.

Technical Specifications

- Material: High-purity zirconium (>99.9% Zr)

- Dimensions: Ø65×65mm (diameter x height)

- Maximum operating temperature: >2,000°C

- Thermal shock resistance: Excellent

- Corrosion resistance: Superior against most acids and alkalis

- Density: 6.51 g/cm³

- Melting point: 1,855°C

- Thermal conductivity: 22.7 W/m·K at 20°C

Key Features and Benefits

- Exceptional thermal stability: Maintains structural integrity at extreme temperatures

- High purity: Minimizes contamination risks in sensitive processes

- Excellent chemical resistance: Suitable for aggressive environments

- Low thermal expansion: Reduces stress during heating and cooling cycles

- Non-magnetic properties: Ideal for applications requiring electromagnetic neutrality

- Long service life: Cost-effective solution for repeated use

- Customizable: Available in various sizes and configurations to meet specific requirements

Applications and Industries Served

Our 【Zirconium Crucible Ø65×65mm For Thermal Processing】 finds extensive use in:

- Materials research and development

- Aerospace component manufacturing

- Semiconductor fabrication

- Specialty alloy production

- Advanced ceramics processing

- Nuclear fuel handling

- High-temperature metallurgy

- Crystal growth experiments

Manufacturing Process

We employ a state-of-the-art manufacturing process to ensure the highest quality and consistency:

- Raw material selection: Sourcing of ultra-pure zirconium

- Precision machining: CNC-controlled shaping for exact dimensions

- Surface treatment: Specialized finishing for enhanced performance

- Heat treatment: Optimized for thermal stability and durability

- Quality inspection: Rigorous testing at each production stage

Quality Control and Testing

Our commitment to quality is unwavering. Each 【Zirconium Crucible Ø65×65mm For Thermal Processing】 undergoes:

- Chemical composition analysis

- Dimensional accuracy verification

- Surface finish inspection

- Thermal cycling tests

- Leak and pressure tests

- Non-destructive testing (NDT) for structural integrity

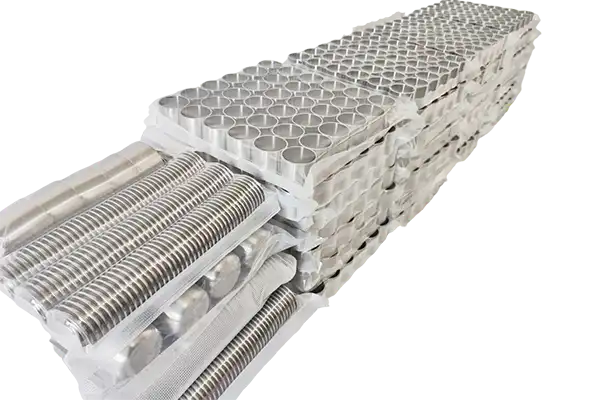

Packaging and Shipping

To ensure safe transit, we package our crucibles in:

- Custom-fitted foam inserts

- Shock-absorbent outer containers

- Moisture-resistant wrapping

- Clear labeling with handling instructions

We offer various shipping options, including express delivery for urgent requirements.

Why Choose Us

- Unmatched expertise in zirconium processing

- Consistent batch-to-batch quality

- Comprehensive technical support and consultation

- Flexible production capabilities for urgent orders

- Competitive pricing without compromising on quality

- Strong track record of on-time deliveries

OEM & Customization Services

We understand that one size doesn't fit all. Our OEM and customization services include:

- Custom dimensions and shapes

- Specialized surface treatments

- Integration of additional features (e.g., lids, handles)

- Material composition adjustments for specific applications

- Batch size flexibility to match your production needs

Certifications and Compliance

Our 【Zirconium Crucible Ø65×65mm For Thermal Processing】 meets or exceeds industry standards:

- ISO 9001:2015 certified manufacturing process

- REACH and RoHS compliant

- AS9100 aerospace quality management system

- Adherence to ASTM standards for zirconium materials

Customer Reviews and Case Studies

"Freelong's zirconium crucibles have significantly improved our alloy development process. Their consistent quality and excellent thermal properties have reduced our experiment times by 30%." - Dr. Sarah Chen, Materials Scientist, Advanced Alloys Inc.

Read more success stories on our website to see how our crucibles have benefited researchers and industries worldwide.

FAQs

- What is the expected lifespan of your zirconium crucibles?

With proper care, our crucibles can last for hundreds of thermal cycles, depending on the specific application and operating conditions. - Can these crucibles be used with reactive metals?

Yes, zirconium's excellent chemical resistance makes it suitable for use with many reactive metals. However, we recommend consulting our technical team for specific compatibility information. - Do you offer rush orders for urgent requirements?

Absolutely. We understand the critical nature of research and production timelines and can accommodate rush orders subject to our current production schedule. - How do I clean and maintain the crucible?

We provide detailed care instructions with each order. Generally, gentle cleaning with non-abrasive materials and proper storage in a dry environment are key to maintaining crucible performance. - Can you provide material certificates with each order?

Yes, we provide full material traceability and certification upon request.

Contact Information

Ready to elevate your thermal processing capabilities? Contact us today to discuss your 【Zirconium Crucible Ø65×65mm For Thermal Processing】 needs.

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Discover the Freelong difference – where precision meets performance in every crucible we craft.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1747983195995.webp)

_1752484362977.webp)

_1745572620134.webp)