- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Zirconium Crucible For Catalyst Testing Ø40mm

Brand: FRL Metal

Surface: polished surface

Grade: Zr702,Zr705,R60001,R60901

Volume:5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc,

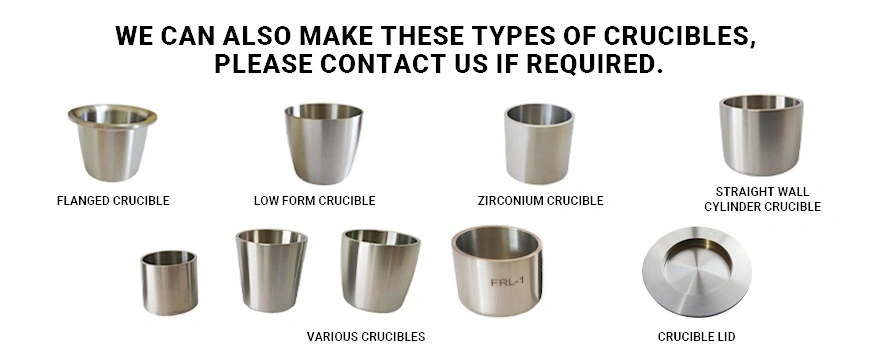

Type: Low form zirconiu crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible

Density: 6.51g/cm3

Minimum Order Quantity:1pc

Sample: available

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Zirconium Crucible For Catalyst Testing Ø40mm: Precision-Engineered for Advanced Research

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of high-quality Zirconium Crucible For Catalyst Testing Ø40mm. Our advanced manufacturing capabilities and deep expertise in non-ferrous metal processing enable us to produce crucibles that meet the exacting standards of catalyst research and development. With our Zirconium Crucible For Catalyst Testing Ø40mm, we offer unparalleled reliability, precision, and performance for your most demanding catalyst testing applications.

Zirconium Crucible For Catalyst Testing Ø40mm picture display

|

|

|

Product Introduction

Our Zirconium Crucible For Catalyst Testing Ø40mm is designed to meet the rigorous demands of chemical and petrochemical R&D labs, catalyst manufacturers, and research institutions. Crafted from high-purity zirconium (Zr≥99.5%), this crucible offers exceptional thermal and chemical resistance, making it ideal for a wide range of catalyst testing protocols.

Technical Specifications

- Diameter: 40mm

- Material: High-purity zirconium (Zr≥99.5%)

- Temperature resistance: Up to 2400°C

- Chemical resistance: Inert to most acids and alkalis

- Surface finish: ≤Ra 0.4μm

- Capacity: Customizable based on height

- Wall thickness: 2mm (standard, can be customized)

Key Features and Benefits

- Superior Purity: Our zirconium crucibles ensure minimal contamination, preserving the integrity of your catalyst samples.

- Exceptional Thermal Stability: Withstands high temperatures without deformation, allowing for consistent results across multiple tests.

- Chemical Inertness: Resistant to most acids and alkalis, preventing unwanted reactions during testing.

- Precision Machined: Uniform wall thickness and smooth surface finish for optimal heat distribution and easy cleaning.

- Durable Construction: Long-lasting performance, reducing the need for frequent replacements and lowering overall costs.

Applications and Industries Served

- Petrochemical catalyst development

- Environmental catalyst research

- Automotive emissions control testing

- Fine chemical synthesis

- Academic research in materials science and catalysis

- Pharmaceutical industry catalyst screening

Manufacturing Process

Our Zirconium Crucible For Catalyst Testing Ø40mm is manufactured using state-of-the-art techniques:

- Raw Material Selection: We source only the highest grade zirconium to ensure purity and consistency.

- Precision Machining: CNC lathes and mills are used to achieve exact dimensions and smooth surfaces.

- Heat Treatment: Carefully controlled processes enhance the crucible's structural integrity and performance.

- Surface Finishing: Advanced polishing techniques create an ultra-smooth interior for easy sample handling.

Quality Control and Testing

Every Zirconium Crucible For Catalyst Testing Ø40mm undergoes rigorous quality checks:

- X-ray fluorescence (XRF) analysis for material composition verification

- Dimensional inspection using high-precision measuring tools

- Surface roughness testing to ensure optimal finish

- Leak testing to guarantee integrity

- Random batch sampling for destructive testing to validate performance

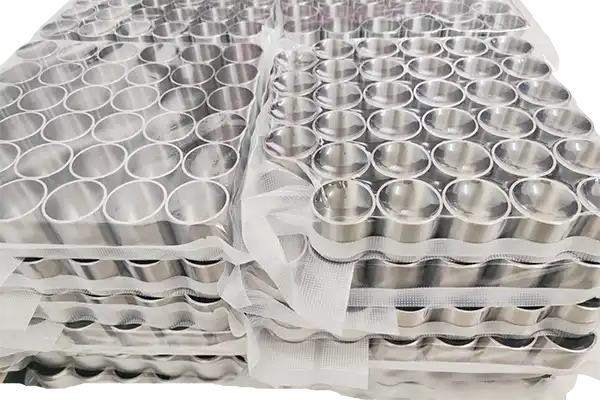

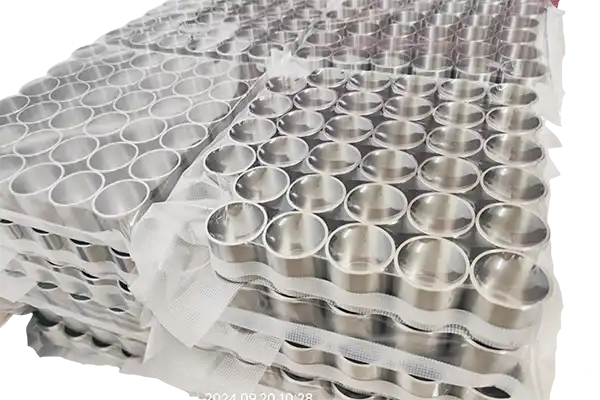

Packaging and Shipping

Our crucibles are individually wrapped in protective foam and placed in sturdy boxes to prevent damage during transit. We offer expedited shipping options to meet urgent research needs and can accommodate both small batch orders and large-scale procurement.

Why Choose Us

- Expertise in Zirconium Processing: With years of experience in non-ferrous metal fabrication, we understand the unique properties of zirconium and how to optimize it for catalyst testing applications.

- Customization Capabilities: Our in-house engineering team can modify designs to meet your specific research requirements.

- Consistent Quality: Our ISO 9001-certified quality management system ensures product reliability and consistency.

- Global Supply Chain: We have established relationships with customers worldwide, ensuring smooth international transactions and timely delivery.

- Technical Support: Our team of experts is available to assist with material selection, testing protocols, and troubleshooting.

OEM & Customization Services

We offer full OEM and customization services for your Zirconium Crucible For Catalyst Testing Ø40mm needs:

- Custom dimensions and shapes

- Specialized surface treatments

- Integration of additional features (e.g., handles, lids)

- Bulk packaging options for industrial users

Certifications and Compliance

- ISO 9001:2015 Quality Management System

- ASTM B523 Standard Specification for Zirconium and Zirconium Alloy Forgings

- RoHS Compliance for applicable products

Customer Reviews and Case Studies

"The Zirconium Crucible For Catalyst Testing Ø40mm from Baoji Freelong has significantly improved the consistency of our catalyst screening process. The precision and durability of these crucibles have allowed us to reduce variables in our experiments and accelerate our research timelines." - Dr. Sarah Chen, Lead Researcher at GreenCat Innovations

FAQs

- What is the typical lead time for Zirconium Crucible For Catalyst Testing Ø40mm?

Standard sizes are usually available within 2-3 weeks. Custom orders may take 4-6 weeks, depending on specifications. - Can you provide material certificates with each order?

Yes, we provide full material traceability and test certificates upon request. - Do you offer sample crucibles for testing before bulk orders?

Absolutely! We encourage customers to evaluate our crucibles in their specific testing environments. - What is the minimum order quantity (MOQ) for Zirconium Crucible For Catalyst Testing Ø40mm?

Our standard MOQ is 5 pieces, but we can accommodate smaller orders for specialized research needs. - How do I clean and maintain the zirconium crucible?

We recommend gentle cleaning with dilute acid solutions and thorough rinsing with deionized water. Avoid abrasive materials that could scratch the surface.

Contact Information

Ready to elevate your catalyst testing with our precision-engineered Zirconium Crucible For Catalyst Testing Ø40mm? Contact us today to discuss your research needs and how we can support your innovations.

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Baoji Freelong New Material Technology Development Co., Ltd. - Your Trusted Partner in Advanced Materials for Catalyst Research.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745570732744.webp)

_1745891086012.webp)

_1755509471954.png)

_1744793935501.webp)