- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

702 Zirconium Plate

Brand: FRL Metal

Density: 6.51g/cm3

Grade: Zr 60702

Purity: >99.5%

Standard: ASTM B551

Certification: ISO9001

Delivery Time:5~7days

Payment Terms:T/T

Packaging Details:Plywood case

What are the advantages of 702 zirconium plate?

702 zirconium plate and zirconium alloy have advantages in special chemical environments (mainly acetic acid and hydrochloric acid). The almost tightly adhering oxide forms the corrosion resistance of zirconium. Therefore, zirconium plates have been used to manufacture reactors and heat exchangers for specific applications. Zirconium products are also widely used in medicine, such as zirconium implants. Zirconium plates are also used as supports and structural members for high temperature applications due to their better mechanical strength at high temperatures. Zirconium has a passivating oxide layer (ZrO2) that renews itself when in contact with aqueous media, constantly telling itself. Among other advantages, Zirconium Zr702 is resistant to almost all organic acids, inorganic acids and alkaline solutions. Zirconium 702 is suitable for welding and is fully recyclable. It is also very ductile at low temperatures.

Application of 702 zirconium plate

702 zirconium plate is a rare metal with excellent corrosion resistance, absolute high melting point, ultra-high hardness and strength. Zirconium plate is mainly used in electronic industry, reaction and atomic energy fields, mainly for the characteristics of zirconium. Also used in valves, pipes, heat exchangers and pumps in chemical plants. These systems are, for example, equipment for the production of acetic acid, hydrochloric acid or urea. Zr702 is used even in the medical field because it is biocompatible and has no toxic effects. Another application of Zirconium 702 is in nuclear technology.

Corrosion resistance of titanium and zirconium

The corrosion resistance and high temperature resistance of titanium are far less than that of zirconium products. Its melting point is about 1600°C, while the melting point of zirconium is above 1800°C. The melting point of zirconium dioxide in the zirconium plate is above 2700 degrees, so the performance of zirconium as an aerospace material is much better than that of titanium in all aspects.

Zirconium sheet chemical composition according to ASTMB551

| Element | Grades | ||||

| / | R60702 | R60704 | R60705 | R60706 | R60700 |

| Zirconium+hafnium,min | 99.2 | 99.2 | 97.5 | 95.5 | 95.5 |

| Hafnium, max | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 |

| lron+chromium | 0.2 max | 0.2 max | 0.2 to 0.4 | 0.2 max | 0.2 max |

| Tin | ... | ... | 1.0 to 2.0 | ... | ... |

| Hydrogen,max | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| Nitrogen,max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

| Carbon,max | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Niobium | --- | 2.0 to 3.0 | 2.0 to 3.0 | ||

| Oxygen,max | 0.1 | 0.16 | 0.18 | 0.18 | 0.16 |

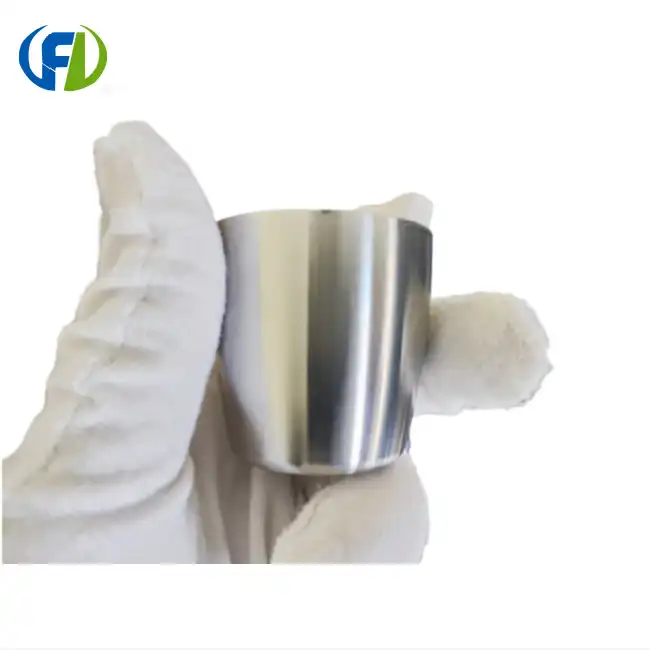

702 Zirconium Plate picture display

|

|

|

FAQ

A. Are you a factory or a trading company?

Our factory has 10 years of production experience.

B. Can you provide samples? MOQ?

Yes, we can provide you with free samples. MOQ: 5kg.

C. Do you accept customization?

Yes, we can process according to your unit weight or drawing.

D. Do you check the finished product?

Yes, every product will be checked by our QC before shipment.

E. How much is the shipping fee?

Mainly depends on weight, volume, package size and destination port.

F. What is your delivery time?

In stock, 7-15 days, if not, according to your quantity.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail: jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745572620134.webp)

_1748240821763.webp)

_1745897261591.webp)