- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

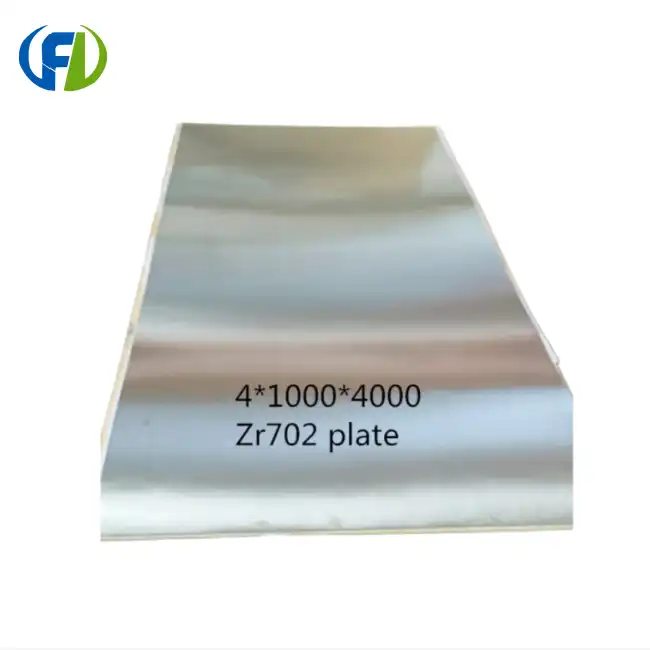

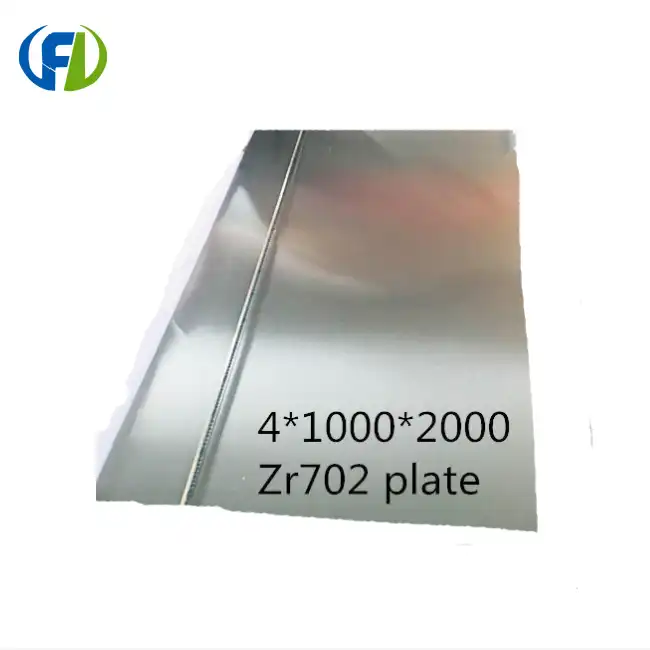

Zirconium 702 Sheet

Brand: FRL Metal

Density: 6.51g/cm3

Grade: Zr702

Standard: ASTM B551

Certification: ISO9001

Delivery Time:5~7days

Payment Terms:T/T

Packaging Details:Plywood case

Characteristics of zirconium 702 sheet

Zirconium 702 sheet have a series of characteristics such as low density, high specific strength, corrosion resistance, radiation resistance, excellent wear resistance, excellent processing performance, non-toxic, non-magnetic, and small thermal neutron absorption cross section.

Zirconium 702 sheet is widely used in those documents

(1) Glass coating and watch coating

(2) Marine and space equipment

(3) Medical use equipment

(4) Sewage treatment

In view of the excellent corrosion resistance of zirconium and zirconium alloys with traditional stainless steel, copper, nickel, titanium and other metal alloys, zirconium and zirconium alloys, they can resist the corrosion of most organic acids, inorganic acids, strong alkalis and some molten salts. In wastewater treatment, food processing, and strong acid production industries, it is mainly used for equipment and components that require high corrosion resistance, such as reactors, acid-resistant pumps, heat pumps, heat exchange tubes, immersion tanks, acid-resistant impellers, valves, etc. , agitators, nozzles and container liners. The zirconium equipment used by American chemical companies has been used for more than 25 years without obvious corrosion damage. The conversion rate is as high as 85%~90%, which greatly improves the production efficiency of the enterprise. In the process of deep-sea exploration, zirconium alloy can not only withstand the erosion of seawater and sand, seawater corrosion and fluid friction and wear, but also adapt to the alternating temperature environment of -200 ~ 200 °C. This is because zirconium has a low coefficient of thermal expansion and can be used stably and continuously. The absorption cross section is small. Greatly improve the production efficiency of enterprises. In the process of deep-sea exploration, zirconium alloy can not only withstand the erosion of seawater and sand, seawater corrosion and fluid friction and wear, but also adapt to the alternating temperature environment of -200 ~ 200 °C. This is because zirconium has a low coefficient of thermal expansion and can be used stably and continuously. The absorption cross section is small. Greatly improve the production efficiency of enterprises. In the process of deep-sea exploration, zirconium alloy can not only withstand the erosion of seawater and sand, seawater corrosion and fluid friction and wear, but also adapt to the alternating temperature environment of -200 ~ 200 °C. This is because zirconium has a low coefficient of thermal expansion and can be used stably and continuously. The absorption cross section is small.

Zirconium 702 Sheet picture display

|

|

|

Our Packaging

Testing Report

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail: jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745830365143.webp)

_1751005735586.webp)

_1745396656566.webp)

_1745570080041.webp)