- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Zr 704 Zirconium

Brand: FRL Metal

Density: 6.51g/cm3

Grade: Zr 60704

Certification: ISO9001

Delivery Time:5~7days

Payment Terms:T/T

Packaging Details:Plywood case

Product introduction

Zr704 zirconium is a silver-gray metal with a steel-like appearance and luster; it is easy to absorb hydrogen, nitrogen and oxygen; zirconium has a strong affinity for oxygen,at a temperature of 1000 °C, oxygen dissolved in zirconium can greatly increase its volume. Most people consider zirconium to be an uncommon metal. In fact, its content in the earth's crust is quite large, which is larger than the commonly used metals such as zinc, copper, and tin. Zirconium alloys can withstand very high temperatures and are used as the first protective shell for nuclear reactions

A layer of oxide film is easily formed on the surface, which is glossy, so the appearance is similar to that of steel. It resists corrosion but is soluble in aqua regia and hydrofluoric acid. At high temperatures, it can react with numerous metal elements as well as non-metallic elements to generate solid solutions. Zirconium is easily produced into plates, wires, and other materials and possesses good plasticity. Zirconium can be used to store hydrogen because it can absorb a lot of oxygen, hydrogen, nitrogen, and other gases when heated. Zirconium has corrosion resistance that is superior to titanium and comparable to that of niobium and tantalum. Hafnium and zirconium are two metals with symbiotic chemical relationships that contain radioactive elements. Zirconium ranks 19th in terms of abundance in the crust, practically on par with chromium. Zirconium-containing minerals with industrial value in nature mainly include zircon and baddeleyite.

The main alloying elements of Zr704 zirconium are tin, niobium, iron and so on. Zirconium alloy has good corrosion resistance, moderate mechanical properties, low atomic thermal neutron absorption cross section in high temperature and high pressure water and steam at 300-400 °C, and has good compatibility with nuclear fuel. Core structural material. In addition, zirconium has excellent corrosion resistance to various acids, alkalis and salts, and has a strong affinity with oxygen, nitrogen and other gases, so zirconium alloys are also used in the manufacture of corrosion-resistant parts and pharmaceutical machinery parts, in the electric vacuum and light bulb industry It is widely used as a non-evaporable getter.

Industrial production of zirconium alloys primarily focuses on the zirconium-tin series and zirconium-niobium series. The previous alloy grades are Zr-2 and Zr-4, whereas Zr-2.5Nb is a typical example of the latter. The alloying components tin, iron, chromium, and nickel can lessen the sensitivity of the surface state to corrosion and improve the strength, corrosion resistance, and thermal conductivity of the corrosion-resistant coating in zirconium-tin alloys. Typically, boiling water reactors employ Zr-2 alloys while pressurized water reactors use Zr-4 alloys. In zirconium-niobium-based alloys, when the addition amount of niobium reaches the solid solution limit of the crystal structure of zirconium at the service temperature, the corrosion resistance of the alloy is very good.When zirconium alloy is heated to a high temperature, its crystal structure is body-centered cubic, whereas when it is cooled to a low temperature, it has a hexagonal close-packed structure. With the help of plastic processing, zirconium alloy may be transformed into pipes, plates, bars, and wires. Its weldability is very good, thus it can be used for welding.

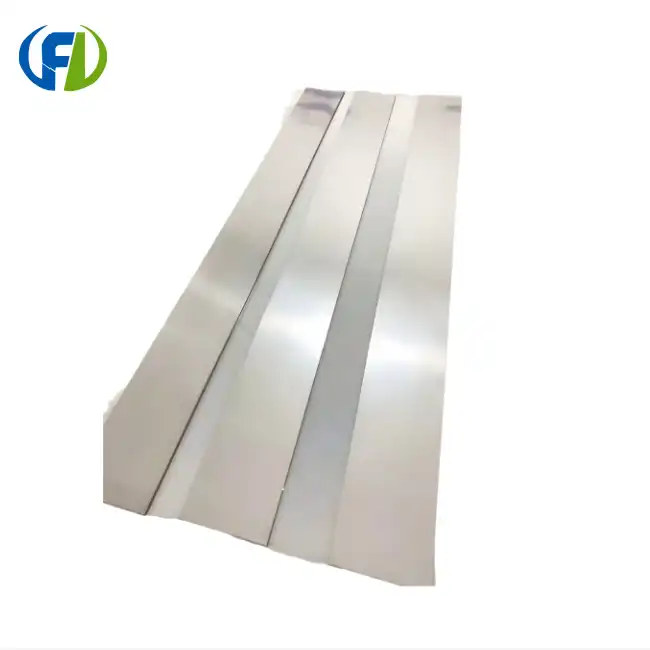

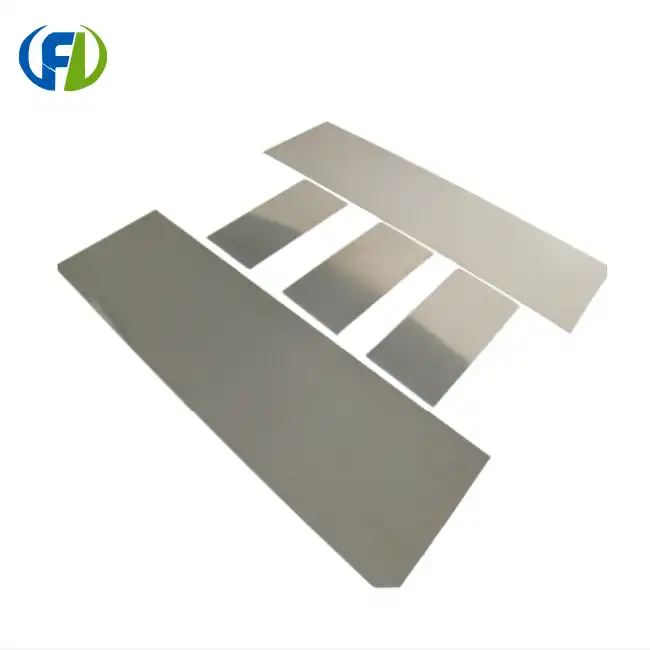

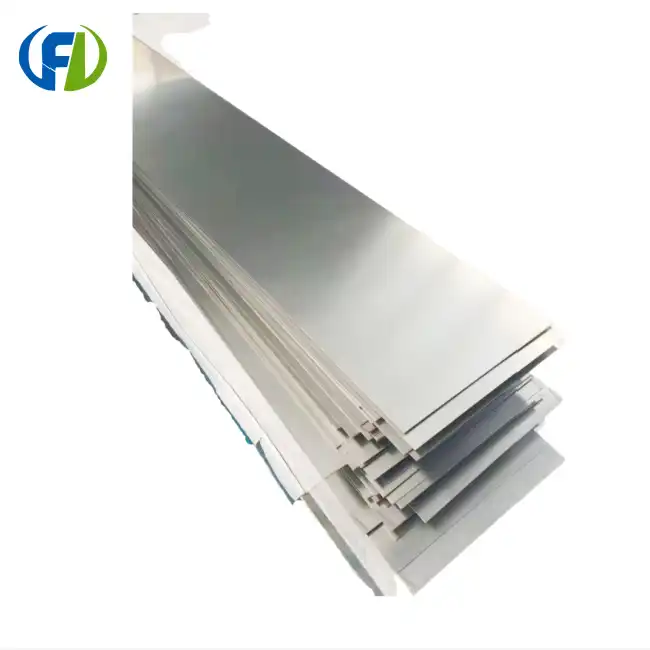

Product image presentation

|

|

|

Product use

Zr704 zirconium has a small thermal neutron capture section and has outstanding nuclear properties. It is an indispensable material for the development of the atomic energy industry and can be used as a reactor core structural material. Zirconium powder is easy to burn in the air and can be used as detonator and smokeless powder. Zirconium can be used as an additive for deoxidation and desulfurization of high-quality steel, and is also a component of armor steel, cannon steel, stainless steel and heat-resistant steel. Zirconium is an important alloying element of magnesium alloys, which can improve the tensile strength and processability of magnesium alloys. Zirconium is also a modifier of aluminum-magnesium alloys, which can refine grains. Zirconium dioxide and zircon are the most valuable compounds in refractory materials. Zirconium dioxide is the main material of new ceramics and cannot be used as a heating material that resists high temperature oxidation. Zirconium dioxide can be used as an additive for acid-resistant enamel and glass, which can significantly improve the elasticity, chemical stability and heat resistance of glass. Zircon has strong light reflection performance and good thermal stability, and can be used as sunscreen in ceramics and glass. Zirconium can absorb a large amount of oxygen, hydrogen, ammonia and other gases when heated, and is an ideal getter. For example, zirconium powder is used as a degassing agent in electronic tubes, and zirconium wire and zirconium sheets are used as grid supports and anode supports.

FAQ

A. Are you a factory or a trading company?

Our factory has 10 years of production experience.

B. Can you provide samples? MOQ?

Yes, we can provide you with free samples. MOQ: 5kg.

C. Do you accept customization?

Yes, we can process according to your unit weight or drawing.

D. Do you check the finished product?

Yes, every product will be checked by our QC before shipment.

E. How much is the shipping fee?

Mainly depends on weight, volume, package size and destination port.

F. What is your delivery time?

In stock, 7-15 days, if not, according to your quantity.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail: jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745715910120.webp)

_1745891337764.webp)

_1755845596126.png)

_1745383467615.webp)