- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

5ml 702 Zirconium Crucible Laboratory

Brand: FRL Metal

Surface: polished surface

Melting point: >=1800℃

Density: 6.51g/cm3

Sample:...

5ml 702 zirconium crucible product instructions

Zirconium crucibles are fragile! Handle with care during unpacking, shipping, handling and cleaning.

Zirconium exhibits excellent corrosion resistance in most organic and inorganic acids, salt solutions, strong bases and a few molten salts. Effective all-purpose crucible for melting using sodium carbonate and sodium peroxide.

Heating zirconium produces a milky white passive oxide film, a corrosion barrier that is stable under both reducing and oxidizing conditions. Check for micro-cracks before heating the crucible and replace with a new zirconium crucible.

Do not over load the zirconium crucible with material, this increases the likelihood of uneven heating.

Argon or helium zirconium crucibles can be heated to 1450°C under vacuum, otherwise use in air is limited to 450°C to 500°C.

It is strongly recommended to use slow heating and cooling rates to minimize thermal shock on the crucible. When heating up, special attention should be paid to two sensitive temperature ranges: 100°C~300°C and 1050°C~1200°C period not exceeding 3°C/MIN. The rate may be faster in other temperature ranges, but less than 5°C/MIN is recommended.

Do not take the zirconium crucible directly out of the furnace at high temperatures or it may break. It is recommended to remove from heat source when the temperature is below 100°C.

Zirconium crucibles should not be heated by torches or furnaces that cannot control the rate of temperature change. Uneven heating can cause cracks!

Picture display

Common problem

A. Are you a factory or a trading company?

Our factory has 10 years of production experience.

B. Can you provide samples? MOQ?

Yes, we can provide you with free samples. MOQ: 1kg.

C. Do you accept customization?

Yes, we can process according to your unit weight or drawing.

D. Do you check the finished product?

Yes, every product will be checked by our QC before shipment.

E. How much is the shipping fee?

Mainly depends on weight, volume, package size and destination port.

F. What is your delivery time?

In stock, 1-2 days, if not, according to your quantity.

Our Packaging

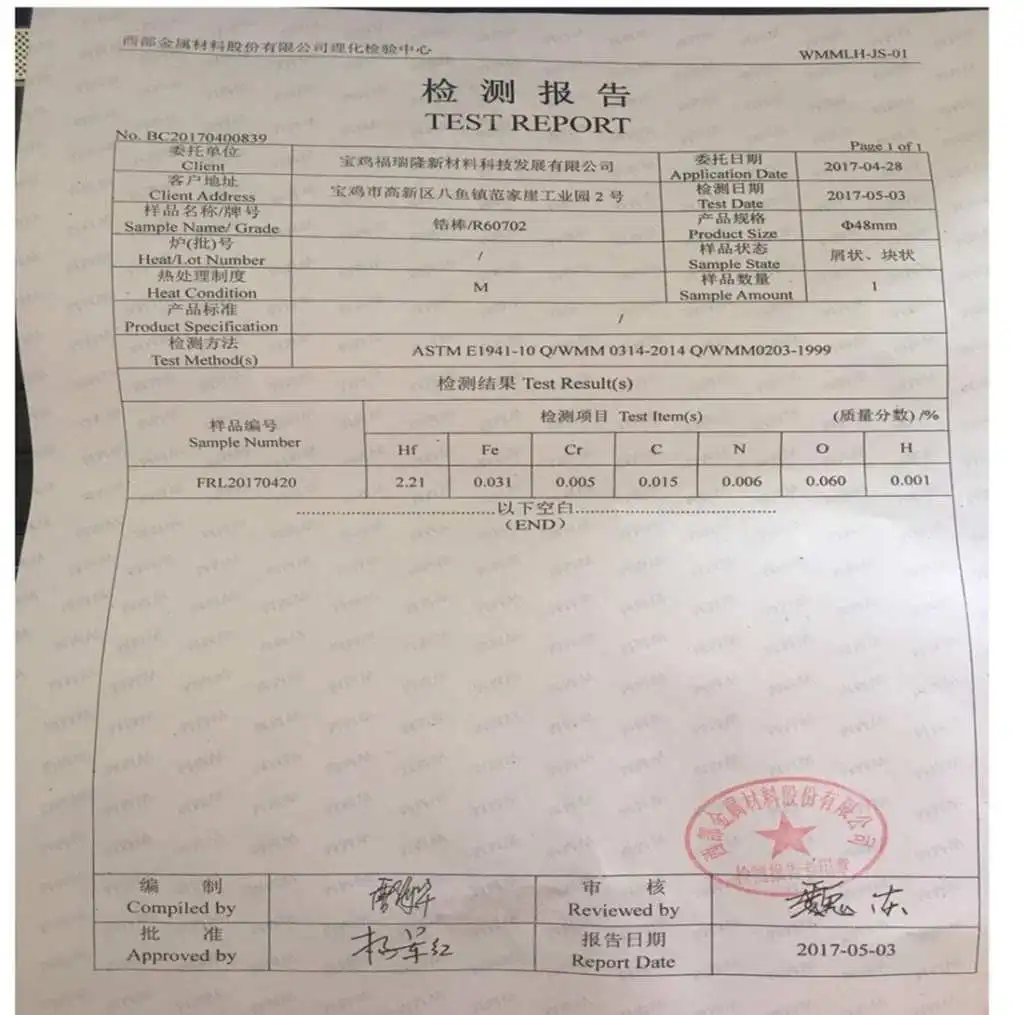

Testing Report

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum,Tungsten,Molybdenum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745288404903.webp)

_1745890101915.webp)

_1745571179057.webp)