- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

zirconium wire coil

Brand: FRL Metal

Density: 6.51g/cm3

Grade: Zr702 Zr705 Zr60001 Zr60804 Zr60901

Diameter: 0.25mm 0.3mm 0.4mm 0.5mm

Standard: ASTM B550

Certification:ISO9001

Delivery Time:5~7days

Payment Terms:T/T

Packaging Details:Plywood case

Zirconium Wire Coil: Premium Quality for High-Performance Applications

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of high-quality zirconium wire coil. With our advanced processing capabilities and years of experience, we deliver superior zirconium products that meet the stringent requirements of various industries. Our zirconium wire coil stands out for its exceptional corrosion resistance, high strength, and thermal stability, making it ideal for demanding applications in nuclear energy, chemical processing, and aerospace sectors.

Product Introduction

Our zirconium wire coil is a versatile and high-performance material designed to excel in challenging environments. Crafted from pure zirconium or zirconium alloys, this wire offers unparalleled resistance to corrosion and heat, making it an essential component in various industrial applications.

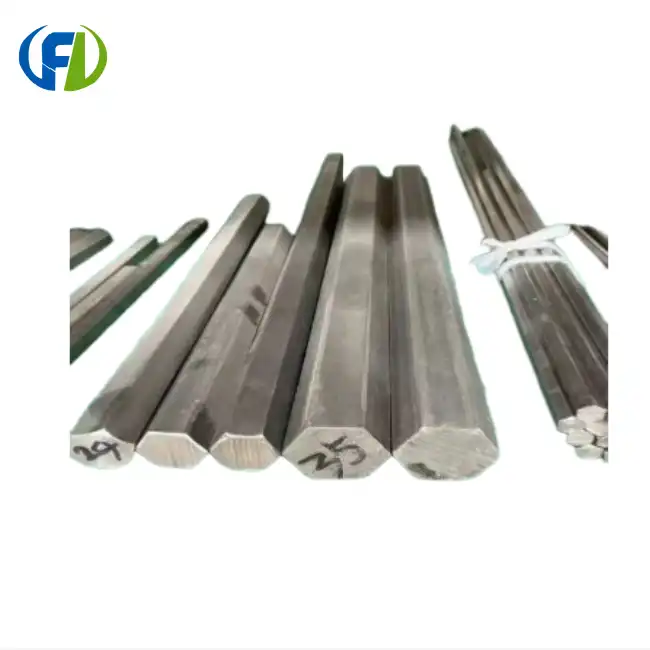

Zirconium wire coil picture display

|

|

|

Technical Specifications

- Material: Pure Zirconium or Zirconium Alloys (e.g., Zr702, Zr705)

- Diameter Range: 0.1mm to 5mm

- Purity: 99.2% to 99.8%

- Density: 6.51g/cm3

- Tensile Strength: 380-550 MPa

- Elongation: ≥20%

- Surface Finish: Bright or Matte

- Packaging: Spools or Custom Packaging

Key Features and Benefits

- Exceptional Corrosion Resistance: Withstands aggressive chemical environments

- High Temperature Stability: Maintains properties at elevated temperatures

- Low Neutron Absorption: Ideal for nuclear applications

- Biocompatibility: Suitable for medical implants and devices

- Customizable Dimensions: Available in various diameters and lengths

- Excellent Ductility: Easy to form and shape for specific applications

Applications and Industries Served

Our zirconium wire coil finds applications in:

- Nuclear Energy: Fuel rod spacers, reactor components

- Chemical Processing: Heat exchangers, piping systems

- Aerospace: High-temperature sensors, specialized components

- Medical Devices: Implants, surgical instruments

- Electronics: Vacuum tube getters, superconductor coatings

Manufacturing Process

We employ a state-of-the-art manufacturing process to ensure the highest quality:

- Raw Material Selection: Sourcing premium-grade zirconium

- Melting and Casting: Precision-controlled vacuum arc remelting

- Hot Working: Forging and rolling to achieve desired dimensions

- Cold Drawing: Multiple passes to attain specified diameter

- Heat Treatment: Optimizing mechanical properties

- Surface Treatment: Cleaning and finishing for superior performance

- Quality Control: Rigorous testing at each production stage

Quality Control and Testing

Our commitment to quality is unwavering. Every batch of zirconium wire coil undergoes:

- Chemical composition analysis

- Mechanical property testing (tensile strength, elongation)

- Dimensional accuracy checks

- Surface defect inspection

- Corrosion resistance testing

- Microstructure examination

Packaging and Shipping

We ensure safe and efficient delivery of our products:

- Vacuum-sealed packaging to prevent contamination

- Sturdy spools or custom packaging options

- Protective outer casing for damage-free transportation

- Detailed labeling for easy identification

- Flexible shipping options to meet your timeline

Why Choose Us

- Expertise: Years of experience in zirconium processing

- Quality Assurance: Strict quality control measures

- Customization: Tailored solutions to meet specific requirements

- Competitive Pricing: Excellent value for premium quality

- Reliable Delivery: On-time shipment and global logistics support

- Technical Support: Expert advice and after-sales service

OEM & Customization Services

We offer comprehensive OEM and customization services:

- Custom alloy compositions

- Specific dimensional requirements

- Special surface treatments

- Unique packaging solutions

- Material certification to meet industry standards

Certifications and Compliance

Our zirconium wire coil meets or exceeds industry standards:

- ISO 9001:2015 Certified

- ASTM B550 Compliant

- REACH Registered

Customer Reviews and Case Studies

"Baoji Freelong's zirconium wire coil has significantly improved the longevity of our chemical processing equipment. Their product quality and technical support are unmatched." - John D., Chief Engineer at XYZ Chemical Corp.

Case Study: A leading nuclear energy company reduced their reactor maintenance downtime by 30% after switching to our high-performance zirconium wire coil for fuel rod spacers.

FAQs

- What is the minimum order quantity for zirconium wire coil?

We offer flexible MOQs to accommodate various project sizes. Contact us for details. - Can you provide material certificates with each order?

Yes, we provide full material traceability and certificates upon request. - What is the lead time for custom orders?

Lead times vary based on specifications. Generally, we can deliver within 2-4 weeks for standard sizes. - Do you offer samples before bulk orders?

Yes, we provide samples for testing and evaluation. Contact our sales team to arrange this. - What industries commonly use zirconium wire coil?

Nuclear energy, chemical processing, aerospace, and medical device industries are primary users of our product.

Trust Baoji Freelong for all your zirconium wire coil needs. Let's innovate together!

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745293060413.webp)

_1745894099771.webp)

_1769676035515.png)