- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

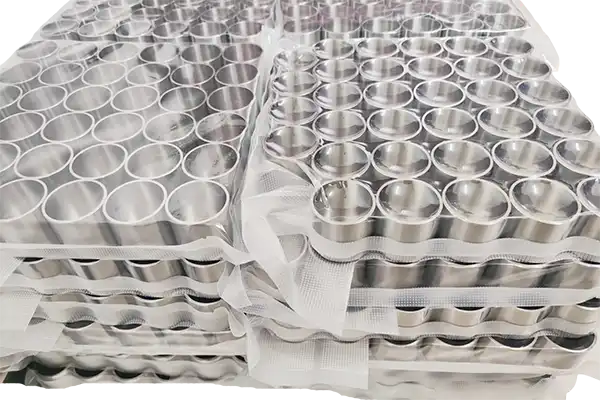

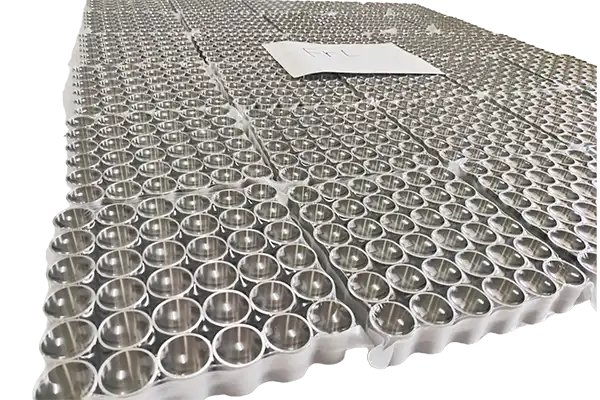

Nickel Crucible

Brand: FRL Metal

Material: pure nickel material (nickel 200)

Density: 8.902 g/cm³

Certification: ISO 9001

Delivery time: 7-15 days

Payment terms: L/C, T/T

Export port: any port in China

Express: Fedex, TNT, DHL and EMS shipping

Nickel crucibles are used in a wide range of laboratories and industries, including but not limited to:

1. High temperature experiment: used for chemical reaction and material property test under various high temperature conditions.

2. Melting test: suitable for melting experiments of molten metals, alloys and other high melting point materials.

3. Powder sintering: In powder metallurgy, it is used to sinter metal and ceramic powders.

4. Heat treatment: used in metal heat treatment process, such as annealing, quenching, etc.

5. High temperature storage: It can be used for storage and preservation of certain materials at high temperature.

Nickel Crucible Picture display

|

|

|

Advantages of nickel crucible:

1. High temperature resistance: Nickel crucible can work at a temperature up to 1300 degrees Celsius, suitable for most high temperature experiments and processes.

2. Good corrosion resistance: Nickel has good corrosion resistance and can resist the erosion of many chemical substances, making it suitable for handling various reagents and materials.

3. Excellent mechanical properties: Nickel material has high tensile strength, which helps to maintain the structural integrity of the crucible under high temperature and high pressure environments.

4. Good thermal conductivity: Nickel has high thermal conductivity, which helps to evenly distribute temperature and improve the efficiency of experiments and heating processes.

5. Easy to clean: The surface of the nickel crucible is smooth, not easy to adhere to material residue, easy to clean and maintain.

Nickel crucibles can be widely used in the following fields:

1. Laboratory research: high-temperature experiments and analysis in the fields of chemistry, physics, materials, etc.

2. Metallurgical industry: used for melting, casting and sintering of metals and alloys.

3. Materials science: for heat treatment, sintering and testing of materials.

4. Powder metallurgy: used in powder metallurgy process for sintering and forming.

5. High temperature storage: It can be used for storage of certain materials under high temperature conditions.

Characteristics and precautions of nickel crucible

1. Nickel crucible cannot be used for precipitate burning.

2. Nickel crucibles are suitable for melting samples in NaOH, Na2O2, Na2CO3, NaHCO3 and alkaline solvents containing KNO3, but not for melting samples in acidic solvents such as KHSO4 or NaHS04, K2S2O7 or Na2S2O7 and alkaline sulfide fluxes containing sulfur.

3. Molten metal salts such as Al, Zn, Pb, Sn, Hg, etc. can make nickel crucibles brittle. Borax cannot be melted in nickel crucibles either.

4. Nickel crucibles often contain trace amounts of chromium, so be careful when using them.

5. The melting point of nickel is 1455 degrees Celsius, and the melting temperature of nickel crucibles should not exceed 700°C, because nickel is easily oxidized at high temperatures.

6. Nickel crucibles often contain trace amounts of chromium, so be careful when using them. A new nickel crucible should first be burned in a muffle furnace to turn it blue-purple to remove oil stains on the surface, then boiled in 1:20 (volume ratio) hydrochloric acid for a while and then rinsed with water.

Summarize:

Nickel crucible is a laboratory and industrial tool with excellent high temperature resistance and corrosion resistance. It plays an important role in high temperature experiment, melting test, powder sintering, heat treatment and high temperature storage, etc. Excellent mechanical properties and thermal conductivity enable stability and high efficiency in high temperature environments. Pay attention to quality assurance when purchasing, and choose products with appropriate specifications and purity to ensure the smooth progress of experiments and industrial processes.

FAQ

Q: What does your company do?

A: We are a scientific and technological innovation enterprise, mainly producing high-end non-ferrous metal materials. The main products involve titanium and titanium alloy rods, wires, plates, pipes, flanges and other titanium industry chain products and other rare and precious metal products.

Q: What are the advantages of your company?

A:

(1): High quality and reasonable price.

(2): Rich experience in after-sales service.

(3): Every process will be inspected by the responsible QC to ensure the quality of every product.

(4): Professional packaging team to ensure the safety of each package.

(5): Trial order can be finished within one week.

(6): Samples are available upon your request.

Q: What about your price?

A: Due to our fine management and cost control, our price is very given. If you are interested, please feel free to contact us.

Q: How long is your delivery time?

A: Different products have different lead times. Usually the delivery time is within 7 to 15 days after we receive your deposit.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1769760390456.png)

_1767777386145.png)

_1745890135003.webp)

_1745738866000.webp)