- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

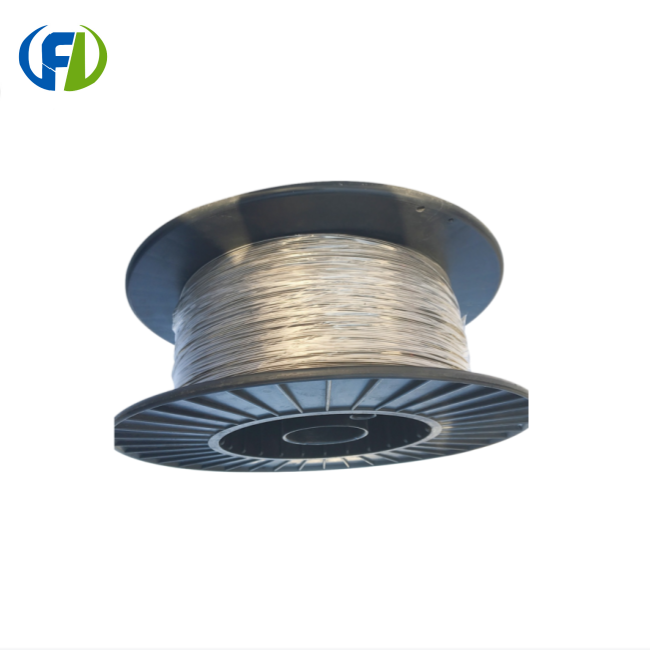

niobium sheet

Brand: FRL Metal

Thickness 0.05–2 mm, width ≤1000 mm.

Purity ≥99.95%,

Density 8.57 g/cm³.

Tensile strength ≥160 MPa, elongation ≥45%.

Used in fabrication of reactors and heaters.

Certification: ISO9001

Delivery Time:5~7days

Payment Terms:T/T

Technical Specifications

Our niobium sheets offer impressive technical characteristics:

Dimensional Range:

- Thickness: 0.05–2 mm

- Width: Up to 1000 mm

- Length: Customizable based on requirements

Material Properties:

- Purity: ≥99.95%

- Density: 8.57 g/cm³

- Fine grain size: ≤50 μm

- Tensile strength: ≥160 MPa

- Elongation: ≥45%

Surface Finish:

- Bright annealed

- Pickled and passivated

- Custom surface treatments available

|

|

|

Key Features and Benefits

Superior Corrosion Resistance

Your projects benefit from niobium's exceptional resistance to acids and high-temperature environments.

Excellent Formability

The fine grain structure ensures stable forming characteristics for complex fabrication requirements.

High-Temperature Performance

Maintains structural integrity and properties at elevated temperatures up to 1200°C.

Biocompatibility

Perfect for medical applications requiring non-toxic, hypoallergenic materials.

Long Service Life

Exceptional durability reduces replacement costs and maintenance requirements.

Applications and Industries Served

Chemical Processing

Reactor vessels, heat exchangers, and corrosion-resistant components.

Electronics Industry

Capacitor manufacturing, superconducting applications, and electronic components.

Medical Technology

Surgical instruments, implants, and medical device components.

Aerospace Applications

High-temperature structural components and specialized alloy production.

Nuclear Industry

Reactor components and nuclear fuel cladding materials.

Manufacturing Process

Our production facility employs advanced techniques to ensure consistent quality:

Raw Material Selection

We source the highest purity niobium ingots from certified suppliers.

Vacuum Melting

Electron beam melting ensures homogeneous microstructure and eliminates impurities.

Rolling Process

Precision cold rolling achieves exact thickness specifications with superior surface finish.

Heat Treatment

Controlled annealing optimizes mechanical properties and grain structure.

Quality Testing

Every batch undergoes comprehensive testing before shipment.

Quality Control and Testing

Your satisfaction depends on consistent quality. Our testing procedures include:

- Chemical composition analysis

- Mechanical property testing

- Dimensional inspection

- Surface quality evaluation

- Microstructure examination

- Non-destructive testing when required

Packaging and Shipping

We protect your investment with professional packaging:

- Wooden crates for large sheets

- Protective film covering

- Moisture-proof wrapping

- Custom packaging solutions available

- Worldwide shipping partnerships

- Fast delivery times

Why Choose Us

Proven Expertise

Over years of experience in refractory metals manufacturing gives you confidence in our capabilities.

Global Reach

We serve customers across Australia, Korea, Germany, US, UK, Malaysia, Middle East, and Taiwan.

Quality Commitment

We never compromise on quality. Your specifications are our minimum standard.

Competitive Pricing

Direct manufacturer pricing without middleman markups saves you money.

Technical Support

Our experienced team provides application guidance and technical assistance.

OEM & Customization Services

Every project has unique requirements. We offer:

- Custom dimensions and specifications

- Special surface treatments

- Alloy modifications

- Technical consultation

- Prototype development

- Volume production capabilities

Whether you need standard dimensions or specialized niobium sheet configurations, our team works closely with you to deliver exactly what your application demands.

Certifications and Compliance

Our manufacturing processes adhere to international standards. We maintain strict quality management systems to ensure consistent product performance.

FAQs

Q: What minimum order quantities do you accept?

A: We accommodate both small prototype orders and large production runs. Contact us to discuss your specific requirements.

Q: How long is the typical lead time?

A: Standard products ship within 2-3 weeks. Custom specifications may require additional time.

Q: Do you provide material certificates?

A: Yes, we provide complete material certificates with every shipment including chemical analysis and mechanical properties.

Q: Can you supply other niobium products?

A: Absolutely. We manufacture rods, wires, tubes, and custom-formed components.

Q: What payment terms do you offer?

A: We offer flexible payment terms including T/T, L/C, and other arrangements for qualified customers.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1770693283769.png)

_1771923661287.png)

_1745892287721.webp)