- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

titanium foil roll

Brand: FRL metal

Density: 4.51g/cm³

Grade: Gr1,Gr2,TA1,TA2,

Standard: ASTM B265

Thickness: 0.02mm to 0.3mm Or As Per Customer's Request

Processing technology: cold rolling/hot rolling

Advantages: high strength and corrosion resistance

Certification: ISO9001

Delivery time: 7-15 days

Packaging Details: Plywood case

Titanium Foil Roll - Premium Quality Metal Solutions

Product Introduction

Looking for a reliable titanium foil roll that delivers exceptional performance in your manufacturing processes? You've found the perfect solution. Our premium titanium foil roll comes from Baoji City, known as China's Titanium Valley, where we've perfected the art of metal processing for years. These rolls offer outstanding corrosion resistance, lightweight properties, and superior durability that make them ideal for your most demanding applications. Each roll features a bright surface finish and consistent thickness that ensures your projects meet the highest standards.

|

|

|

Technical Specifications

Our titanium foil delivers precise specifications that meet your exact requirements:

Dimensions:

- Continuous roll width: 100mm to 610mm

- Thickness range: 0.02mm to 0.3mm

- Custom lengths available upon request

Material Properties:

- Grade1 Grade2 pure titanium

- Bright surface finish

- Excellent formability

- Superior strength-to-weight ratio

Physical Characteristics:

- Density: 4.51 g/cm³

- Melting point: 1,668°C

- Excellent thermal conductivity

- Outstanding chemical resistance

Key Features and Benefits

When you choose our titanium products, you get unmatched advantages:

Superior Quality: Each roll undergoes strict quality control to ensure consistent thickness and surface quality throughout.

Easy Handling: Supplied on convenient spools that make unwinding and processing simple and efficient.

Versatile Applications: Perfect for complex forming operations, chemical processing, and precision manufacturing.

Cost-Effective: Our competitive pricing helps you reduce material costs without compromising quality.

Reliable Supply: Consistent availability ensures your production schedules stay on track.

Applications and Industries Served

Our titanium materials serve diverse industries where performance matters:

Aerospace Industry: Aircraft components, engine parts, and structural elements that require lightweight yet strong materials.

Battery Manufacturing: Electrode substrates and current collectors in advanced battery systems.

Chemical Processing: Reactor components, heat exchangers, and piping systems in corrosive environments.

Medical Devices: Surgical instruments and implantable devices where biocompatibility is crucial.

Electronics: Precision components in electronic devices and semiconductor applications.

Manufacturing Process

Our advanced production methods ensure consistent quality:

We start with high-purity titanium ingots that undergo careful melting and casting. The material then passes through precision rolling mills where thickness is controlled to exact specifications. Multiple rolling passes gradually reduce thickness while maintaining surface quality. Heat treatment processes optimize mechanical properties and stress relief.

Quality monitoring occurs at every step to ensure your titanium foil roll meets specifications.

Quality Control and Testing

Your success depends on consistent material quality. That's why we implement comprehensive testing:

- Dimensional accuracy verification

- Surface quality inspection

- Mechanical property testing

- Chemical composition analysis

- Corrosion resistance evaluation

Each batch receives certification documenting all test results before shipment.

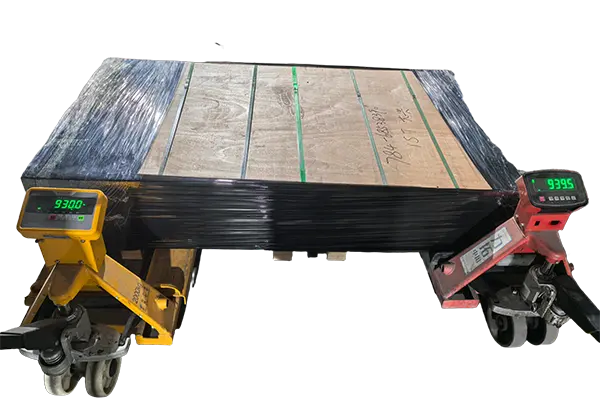

Packaging and Shipping

We protect your investment with careful packaging:

- Moisture-resistant wrapping prevents oxidation

- Protective cores prevent deformation

- Secure packaging ensures safe transport

- Clear labeling identifies specifications

- Efficient logistics minimize delivery time

Why Choose Us

Baoji Freelong New Material Technology Development brings decades of expertise to every order:

Location Advantage: Based in China's Titanium Valley, we have access to premium raw materials and specialized expertise.

Global Reach: We serve customers in Australia, Korea, Germany, US, UK, Malaysia, Middle East, Taiwan, and beyond.

Quality Commitment: We never compromise on quality and take full responsibility for product performance.

Technical Support: Our engineering team provides guidance for your specific applications.

OEM & Customization Services

Every application has unique requirements. We offer:

- Custom width and thickness specifications

- Special surface treatments

- Unique packaging requirements

- Modified alloy compositions

- Application-specific property optimization

Our technical team works closely with you to develop the perfect solution for your needs.

Certifications and Compliance

We maintain strict adherence to international standards and industry requirements. Our quality management system ensures consistent product quality and reliable supply chain performance.

FAQs

Q: What's the minimum order quantity?

A: We work with various order sizes. Contact us to discuss your specific requirements.

Q: Can you provide material certificates?

A: Yes, we provide complete material certification with every shipment.

Q: What's the typical lead time?

A: Lead times vary based on specifications and quantity. We'll provide accurate timing with your quote.

Q: Do you offer technical support?

A: Absolutely. Our engineering team provides application guidance and technical assistance.

Q: Can you customize specifications?

A: Yes, we specialize in custom solutions tailored to your exact requirements.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1768961726418.png)

_1745736483765.webp)

_1769762752724.png)