- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

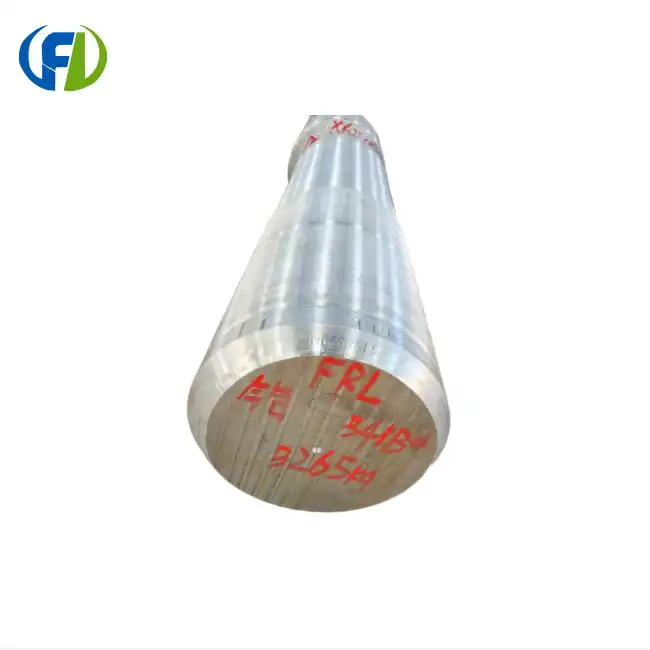

High Stability Zirconium Crucible 2100°C

Brand: FRL Metal

Surface: polished surface

Grade: Zr702,Zr705,R60001,R60901

Volume:5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc,

Type: Low form zirconiu crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible

Surface: bright

Density: 6.51g/cm3

Minimum Order Quantity:1pc

Sample: available

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

High Stability Zirconium Crucible 2100°C - Ultimate Solution for Extreme Temperature Applications

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of High Stability Zirconium Crucible 2100°C. Our advanced manufacturing capabilities and strict quality control ensure that our zirconium crucibles meet the highest industry standards. With years of experience in non-ferrous metal processing, we offer superior products that withstand extreme temperatures and corrosive environments.

|

|

|

Product Introduction

Our High Stability Zirconium Crucible 2100°C is designed for the most demanding high-temperature applications. These crucibles are essential tools in advanced materials research, semiconductor production, and metallurgy. They offer exceptional thermal stability, chemical inertness, and durability, making them ideal for processes requiring ultra-high temperatures and precision.

Technical Specifications

- Material: High-purity zirconium (99.9% Zr)

- Maximum operating temperature: 2100°C

- Melting point: 1855°C

- Density: 6.51 g/cm³

- Thermal conductivity: 22.7 W/m·K at 25°C

- Specific heat capacity: 278 J/kg·K at 25°C

- Available sizes: Custom dimensions upon request

Key Features and Benefits

- Extreme temperature resistance up to 2100°C

- Excellent chemical inertness against molten metals and corrosive materials

- High thermal shock resistance

- Low thermal expansion coefficient for dimensional stability

- Long service life, reducing replacement frequency and costs

- Customizable shapes and sizes to fit specific applications

Applications and Industries Served

Our High Stability Zirconium Crucible 2100°C finds applications in various high-tech industries:

- Semiconductor manufacturing

- Advanced materials research and development

- Aerospace and defense

- Optical fiber production

- Single crystal growth

- High-temperature metallurgy

Manufacturing Process

We employ state-of-the-art manufacturing techniques to produce our zirconium crucibles:

- Raw material selection and purification

- Powder preparation and pressing

- Sintering under controlled atmosphere

- Precision machining and finishing

- Rigorous quality control and testing

Quality Control and Testing

Every High Stability Zirconium Crucible 2100°C undergoes extensive testing:

- X-ray fluorescence (XRF) analysis for material composition

- Microstructure examination using scanning electron microscopy (SEM)

- Thermal cycling tests to ensure stability at extreme temperatures

- Dimensional accuracy checks

- Visual inspection for surface defects

Packaging and Shipping

We ensure safe delivery of your High Stability Zirconium Crucible 2100°C:

- Custom-designed protective packaging

- Shock-absorbent materials to prevent damage during transit

- Clear labeling and handling instructions

- Flexible shipping options to meet your timeline

Why Choose Us

- Expertise in non-ferrous metal processing

- Cutting-edge manufacturing facilities

- Strict quality control measures

- Customization capabilities

- Excellent customer support

- Competitive pricing

- On-time delivery

OEM & Customization Services

We offer full OEM and customization services for our High Stability Zirconium Crucible 2100°C:

- Custom dimensions and shapes

- Specialized coatings or surface treatments

- Integration of additional features (e.g., handles, pouring spouts)

- Tailored packaging solutions

Certifications and Compliance

Our products and processes meet international standards:

- ISO 9001:2015 certified quality management system

- ASTM B493 compliant for zirconium and zirconium alloy forgings

- RoHS and REACH compliant

Customer Reviews and Case Studies

"The High Stability Zirconium Crucible 2100°C from Baoji Freelong has significantly improved our semiconductor production process. Its exceptional thermal stability and longevity have reduced our downtime and increased overall efficiency." - Leading Semiconductor Manufacturer

"We've been using Baoji Freelong's zirconium crucibles for our advanced materials research, and the results have been outstanding. Their customization options allowed us to design crucibles that perfectly fit our unique experimental setups." - R&D Institute Director

FAQs

- What makes zirconium crucibles suitable for high-temperature applications?

Zirconium crucibles offer excellent thermal stability, chemical inertness, and resistance to thermal shock, making them ideal for extreme temperature environments. - Can you customize the size and shape of the crucibles?

Yes, we offer full customization services to meet your specific requirements. - How long do these crucibles typically last?

The lifespan depends on the specific application and usage conditions, but our High Stability Zirconium Crucible 2100°C is designed for extended service life. - Are these crucibles suitable for use with corrosive materials?

Yes, zirconium crucibles exhibit excellent resistance to many corrosive substances, including molten metals and aggressive chemicals. - What safety precautions should be taken when using these crucibles?

Always follow proper handling procedures for high-temperature equipment and wear appropriate personal protective equipment.

Experience the difference with Baoji Freelong's superior zirconium crucibles – where quality meets innovation in extreme temperature solutions.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1744789998889.webp)

_1745724202241.webp)

_1745545136936.webp)