- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

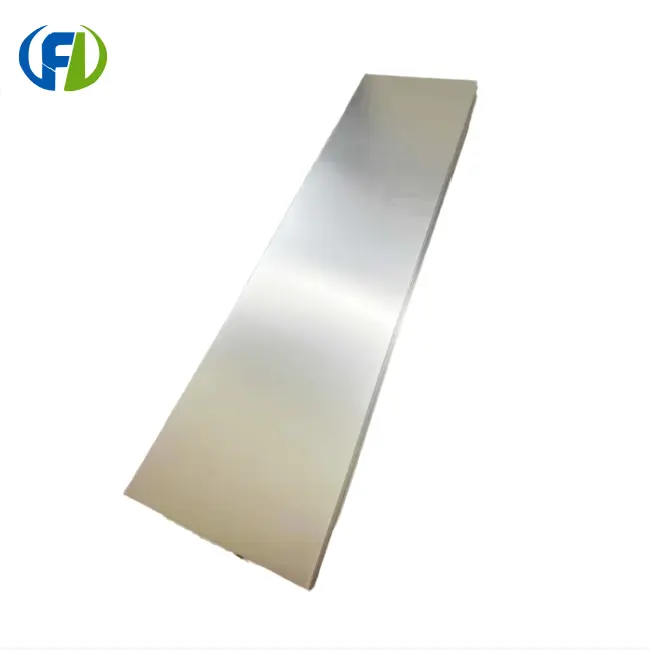

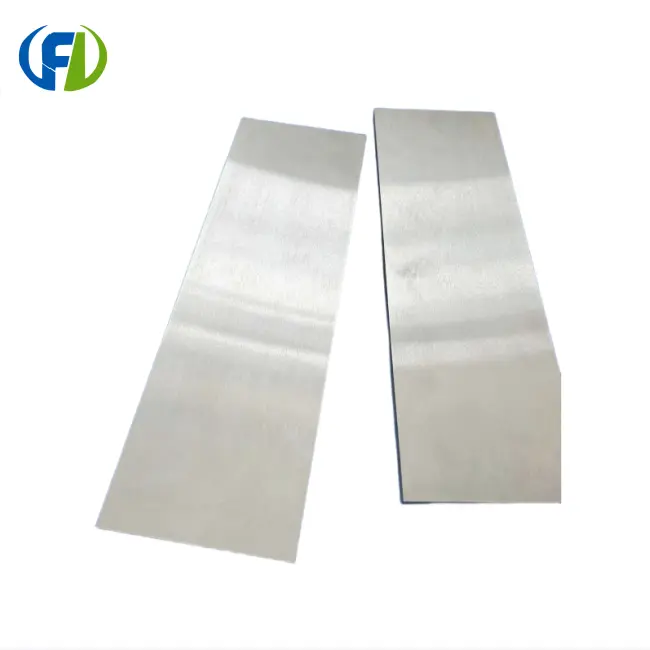

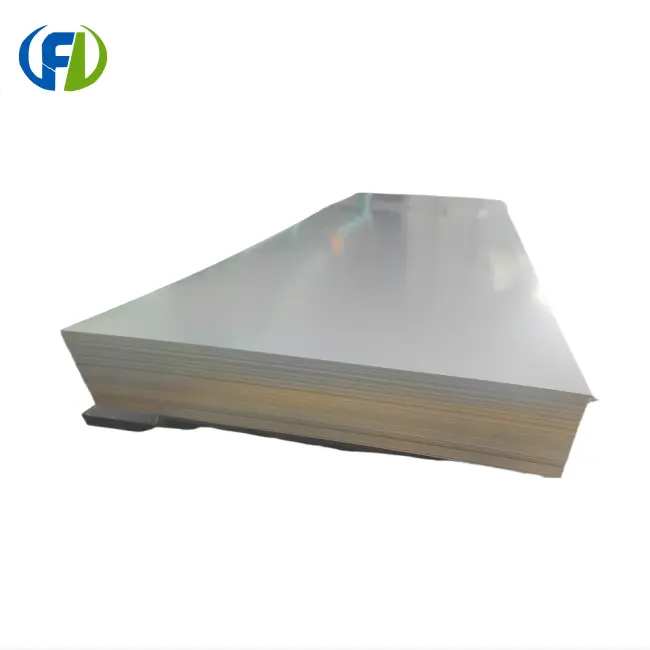

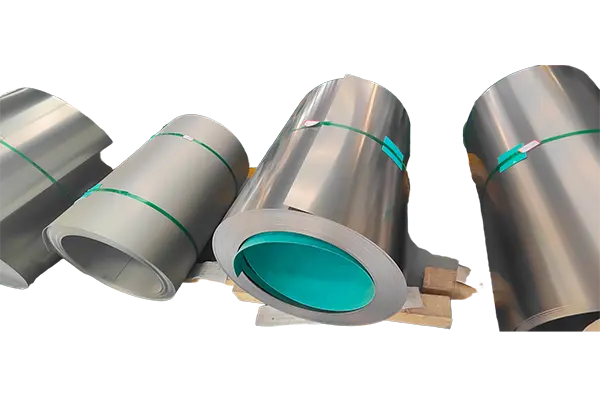

sheets of titanium

Brand: FRL metal

Density: 4.51g/cm³

Grade: Gr1,Gr2,Gr3,Gr4,Gr5,Gr7,Gr9,Gr12,TA1,TA2,TA3,TA9,TA18

Standard: ASTM B265 / ASME SB-265

Thickness: 0.5mm 0.6mm 1mm 2mm 3mm 4mm Or As Per Customer's Request

Processing technology: cold rolling/hot rolling

Advantages: high strength and corrosion resistance

Certification: ISO9001

Delivery time: 7-15 days

Packaging Details: Plywood case

Sheets of Titanium - Premium Quality for Industrial Applications

Looking for high-performance sheets of titanium that deliver exceptional corrosion resistance and strength? Baoji Freelong New Material Technology Development Co., Ltd. offers premium titanium sheets engineered for demanding industrial applications. Our titanium products combine superior durability with lightweight properties, making them perfect for marine environments, chemical processing, and aerospace applications. Located in China's renowned Titanium Valley, we specialize in manufacturing top-quality sheets of titanium that meet international standards and exceed customer expectations.

|

|

|

Technical Specifications

Our titanium sheets come with comprehensive specifications designed to meet your exact requirements:

Available Grades:

- Grade 1 (Gr1) - Commercially pure, maximum corrosion resistance

- Grade 2 (Gr2) - Most common grade, excellent formability

- Grade 3 (Gr3) - Higher strength than Gr2

- Grade 4 (Gr4) - Highest strength commercially pure grade

- Grade 5 (Gr5) - Titanium alloy with aluminum and vanadium

Dimensional Range:

- Width: 1000-1500 mm

- Thickness: 0.3-5 mm

- Length: Customizable based on your needs

Surface Finish:

- Polished surface for enhanced appearance

- Smooth finish reducing contamination risks

- Consistent quality across entire sheet surface

Chemical Of Titanium plate sheet:

| Grade | Ti | Al | V | Fe | C | N | H | O | Other Max |

| Grade1 | Balance | - | - | 0.2 | 0.8 | 0.03 | 0.015 | 0.18 | 0.4 |

| Grade2 | Balance | - | - | 0.3 | 0.8 | 0.03 | 0.015 | 0.25 | 0.4 |

| Grade3 | Balance | - | - | 0.3 | 0.8 | 0.05 | 0.015 | 0.35 | 0.4 |

| Grade4 | Balance | - | - | 0.5 | 0.8 | 0.05 | 0.015 | 0.4 | 0.4 |

| Grade5 | Balance | 5.5-6.75 | 3.5-4.5 | 0.4 | 0.8 | 0.05 | 0.015 | 0.5 | 0.4 |

| Grade7 | Balance | - | - | 0.03 | 0.8 | 0.03 | 0.015 | 0.25 | 0.4 |

| Grade9 | Balance | - | - | 0.25 | 0.8 | 0.03 | 0.015 | 0.15 | 0.4 |

| Grade12 | Balance | - | - | 0.3 | 0.8 | 0.03 | 0.015 | 0.25 | 0.4 |

Key Features and Benefits

Superior Corrosion Resistance

Your titanium sheets withstand harsh chemical environments without degradation. This exceptional resistance extends product lifespan significantly.

Lightweight Yet Strong

You get materials that are 40% lighter than steel while maintaining comparable strength. This weight reduction improves efficiency in your applications.

Excellent Formability

Our sheets bend, shape, and weld easily without cracking. You can create complex geometries with confidence.

Biocompatibility

These materials are safe for medical and food-grade applications. You never compromise on safety standards.

Applications and Industries Served

Marine Industry

Ship hulls, propeller shafts, and offshore equipment benefit from titanium's saltwater resistance. Your vessels operate longer with minimal maintenance.

Chemical Processing

Heat exchangers, reactor vessels, and piping systems perform reliably in corrosive environments. You reduce downtime and replacement costs.

Aerospace Sector

Aircraft components, engine parts, and structural elements require titanium's strength-to-weight ratio. Your aircraft achieve better fuel efficiency.

Medical Field

Surgical instruments, implants, and medical devices rely on titanium's biocompatibility. You ensure patient safety and device longevity.

Manufacturing Process

We employ advanced manufacturing techniques to produce consistent, high-quality products. Our process begins with premium raw materials sourced from certified suppliers. Hot rolling and cold rolling operations create precise thickness specifications.

Annealing treatments optimize mechanical properties and grain structure. Surface polishing removes imperfections and creates the desired finish. Each production step follows strict quality protocols ensuring reliable performance.

Quality Control and Testing

Every batch undergoes comprehensive testing before shipment. Chemical composition analysis verifies grade specifications. Mechanical testing confirms tensile strength and elongation values.

Dimensional inspection ensures thickness and width tolerances. Surface quality examination identifies any defects. Ultrasonic testing detects internal discontinuities. You receive materials that meet or exceed industry standards.

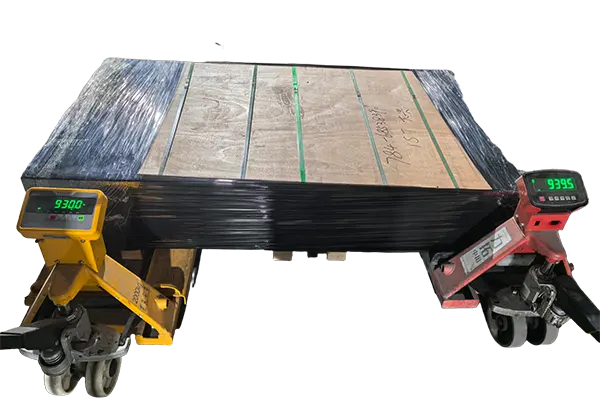

Packaging and Shipping

Your orders receive careful packaging protecting against damage during transit. Protective films prevent surface scratches. Wooden crates provide structural support for larger quantities.

We coordinate with reliable shipping partners ensuring timely delivery. Export documentation includes material certificates and test reports. Tracking information keeps you informed throughout shipping.

Why Choose Us

Strategic Location Advantage

Based in Baoji City, China's Titanium Valley, we access the best raw materials and manufacturing expertise. This location advantage translates to better quality and competitive pricing for you.

Global Partnership Network

We maintain strong relationships with clients across Australia, Korea, Germany, United States, United Kingdom, Malaysia, and Middle East regions. Our international experience helps us understand your specific requirements.

Quality-First Philosophy

Quality remains our primary responsibility. We never compromise on specifications or accept quality failures. This commitment ensures you receive reliable products every time.

Responsive Service

Our team responds quickly to inquiries and provides technical support throughout your project. You get the assistance needed for successful implementation.

OEM & Customization Services

We understand that standard sizes might not fit every application. Our customization capabilities include specific dimensions, surface treatments, and grade modifications.

Whether you need unique specifications or special packaging requirements, our engineering team works with you to develop solutions. Custom orders receive the same quality attention as standard products.

Certifications and Compliance

Our manufacturing processes comply with international quality standards. We maintain certifications ensuring consistent product quality and reliable supply chain management.

Regular audits verify continued compliance with industry requirements. Documentation packages include material certificates, test reports, and compliance statements supporting your quality systems.

FAQs

What minimum quantities do you supply?

We accommodate both small prototype orders and large production volumes. Contact us to discuss your specific quantity requirements.

Can you provide custom dimensions?

Yes, we offer customization services for width, length, and thickness specifications beyond our standard ranges.

What lead times should I expect?

Standard products typically ship within 2-3 weeks. Custom orders may require 4-6 weeks depending on specifications.

Do you provide technical support?

Our experienced team offers comprehensive technical assistance including material selection guidance and application recommendations.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745906604708.webp)

_1750667302331.webp)

_1763520346907.png)

_1745889501501.webp)