- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

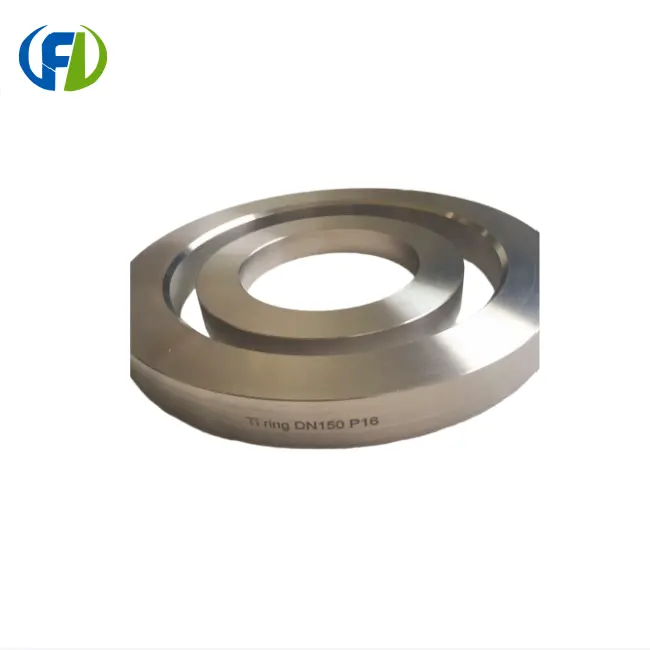

Gr5 Titanium Ring

Brand: FRL metal

Material: titanium

Density: 4.51g/cm³

Grade: Gr5

Surface: Bright

Size: Customizable

Surface: polished/pickling

Certification: ISO9001

Delivery Time: 5~7days

Packaging Details: Plywood case

Technical Parameters of Gr5 Titanium Ring

The technical parameters of titanium ring vary according to specific uses and industry needs, mainly including the following aspects:

Material

Common materials: titanium alloy (such as Gr5).

Chemical composition: in line with international standards such as ASTM B381 or GB/T 3621.

Dimensions

Outer diameter: 100mm–3000mm (customizable).

Inner diameter: 50mm–2800mm (customizable).

Thickness: 5mm–500mm.

Mechanical properties

Tensile strength: ≥350 MPa (pure titanium), ≥900 MPa (titanium alloy).

Yield strength: ≥275 MPa (pure titanium), ≥800 MPa (titanium alloy).

Elongation: ≥20%.

Process requirements

Heat treatment: annealing or solution treatment.

Surface treatment: mechanical polishing, pickling or sandblasting.

Gr5 Titanium Ring display picture

|

|

|

Gr5 Titanium Ring Advantages

1. Lightweight and high strength

The density of titanium is only 60% of that of steel, but it has the same strength as steel.

2. Strong corrosion resistance

Titanium exhibits excellent corrosion resistance in seawater, chlorine, strong acids and alkalis.

3. Excellent high and low temperature performance

The titanium ring can still maintain good mechanical properties at temperatures up to 600°C and show extraordinary toughness in low temperature environments.

4. Good biocompatibility

Non-toxic, no allergic reaction, can be in contact with organisms for a long time.

5. Long life

The durability of titanium products under extreme conditions makes their service life far exceed that of traditional materials in many fields.

Gr5 Titanium Ring Applications

Titanium rings are widely used in many industries, including:

1. Aerospace

Used in the manufacture of aircraft engine parts, such as annular connectors and fasteners, and are favored for their high specific strength and high temperature resistance.

2. Chemical equipment

As sealing rings or connectors in reactors, heat exchangers and piping systems, they can cope with strong acid and alkali environments due to their excellent corrosion resistance.

3. Medical devices

Used in accessories for artificial joints and orthopedic implants, the biocompatibility of titanium materials ensures their long-term stability in the human body.

4. Marine engineering

Used in the manufacture of fasteners and structural parts for submarines and offshore platforms, they can maintain stable performance in high salinity environments.

5. Other fields

Such as automobile manufacturing, sports equipment, nuclear industry, etc.

Our advantage

Baoji Freelong New Material Technology Development Co., Ltd. located in "China Titanium Valley - Baoji". We specialize in the production and export of various non-ferrous metals from China, such as commercially pure titanium and titanium alloys, zirconium, tantalum, niobium and nickel products. Our products are exported to Southeast Asia, Europe, and North America, and are well received by customers. Our motto is "Good Quality, Favorable Price, Fast Delivery". We are always ready to be your sincere friend first, and then your trustworthy business partner!

Our Packaging

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745741768272.webp)

_1745894478073.webp)

_1753152338201.webp)

_1745739563300.webp)