- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High Density Zirconium Crucible For Arc Furnace

Brand: FRL Metal

Surface: polished surface

Density: 6.51g/cm3

Minimum Order Quantity:1pc

Sample: available

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

High Density Zirconium Crucible For Arc Furnace: Superior Performance for Extreme Conditions

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of High Density Zirconium Crucible For Arc Furnace. Our advanced crucibles offer unparalleled thermal stability, corrosion resistance, and longevity, making them ideal for high-temperature metallurgical processes. With years of expertise in non-ferrous metal processing, we deliver premium quality crucibles that meet the stringent demands of various industries.

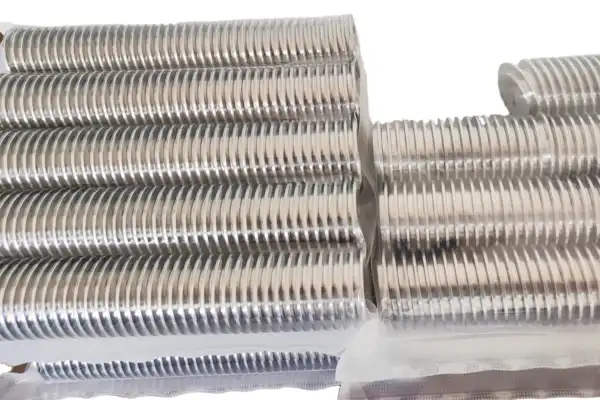

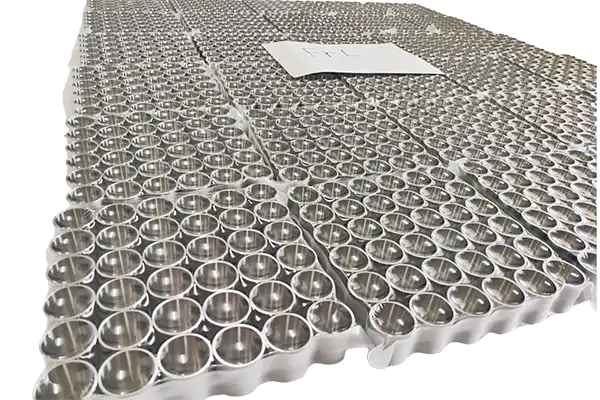

High Density Zirconium Crucible For Arc Furnace picture display

|

|

|

Product Introduction

Our High Density Zirconium Crucible For Arc Furnace is engineered to withstand extreme temperatures and harsh operating conditions. These crucibles are essential components in arc furnaces, enabling the melting and processing of high-purity metals and alloys. Crafted from premium-grade zirconium, our crucibles offer exceptional performance and reliability for demanding industrial applications.

Technical Specifications

- Material: High-density zirconium (99.9% purity)

- Temperature resistance: Up to 2,200°C

- Density: ≥6.0 g/cm³

- Thermal shock resistance: Excellent

- Chemical inertness: Superior

- Available sizes: Custom dimensions to fit your arc furnace

- Wall thickness: Optimized for thermal efficiency

Key Features and Benefits

- Exceptional thermal stability

- Superior corrosion resistance

- Extended service life

- High purity maintenance

- Excellent thermal shock resistance

- Customizable designs

- Consistent performance under cyclic heating

Applications and Industries Served

Our High Density Zirconium Crucible For Arc Furnace finds applications in:

- High-purity metal smelting

- Specialty alloy production

- Rare earth element refining

- Semiconductor manufacturing

- Advanced ceramics production

- Nuclear technology research

- Aerospace material development

Manufacturing Process

We employ state-of-the-art manufacturing techniques to ensure the highest quality:

- Raw material selection and testing

- Precision molding and shaping

- Controlled sintering process

- Surface finishing and quality inspection

- Custom treatments (if required)

Quality Control and Testing

Every High Density Zirconium Crucible For Arc Furnace undergoes rigorous testing:

- X-ray fluorescence (XRF) analysis for material purity

- Density measurements

- Thermal shock resistance tests

- Dimensional accuracy checks

- Visual inspections for defects

Packaging and Shipping

We ensure safe delivery of your crucibles:

- Custom-designed protective packaging

- Shock-absorbing materials

- Sealed containers for moisture protection

- Detailed handling instructions

- Flexible shipping options (air, sea, or land)

Why Choose Us

- Proven track record in non-ferrous metal processing

- Customization capabilities to meet specific requirements

- Strict quality control measures

- Fast turnaround times and reliable delivery

- Competitive pricing for premium products

- Expert technical support and after-sales service

OEM & Customization Services

We offer tailored solutions to meet your unique needs:

- Custom dimensions and shapes

- Specialized coatings or treatments

- Material composition adjustments

- Performance optimization for specific applications

Certifications and Compliance

Our High Density Zirconium Crucible For Arc Furnace meets international standards:

- ISO 9001:2015 certified manufacturing process

- ASTM and ISO material compliance

- RoHS and REACH compliant

- Full material traceability

Customer Reviews and Case Studies

"Freelong's zirconium crucibles have significantly improved our titanium smelting efficiency. Their durability and performance are unmatched." - Chief Engineer, Leading Aerospace Materials Manufacturer

"We've seen a 30% increase in production uptime since switching to Freelong's crucibles. Their technical support is excellent." - Production Manager, Specialty Alloys Company

FAQs

Q: What is the typical lifespan of your High Density Zirconium Crucible For Arc Furnace?

A: Under normal operating conditions, our crucibles can last for hundreds of melting cycles, significantly outperforming traditional alternatives.

Q: Can you provide crucibles for experimental or small-scale operations?

A: Yes, we offer crucibles in various sizes, including those suitable for research and development purposes.

Q: How do you ensure the purity of the zirconium used in your crucibles?

A: We source only the highest grade zirconium and conduct rigorous purity tests throughout the manufacturing process.

Contact Information

Ready to elevate your arc furnace operations with our High Density Zirconium Crucible For Arc Furnace? Contact us today for expert advice and quotations.

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Discover the Freelong difference – where quality meets innovation in high-temperature metallurgy.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745906604708.webp)

_1768468826104.png)

_1744860224255.webp)

_1745829409942.webp)