- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Zirconium Alloy Crucible

Brand: FRL Metal

Surface: polished surface

Density: 6.51g/cm3

Minimum Order Quantity:1pc

Sample: available

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Zirconium Alloy Crucibles: High-Performance Solutions for Extreme Environments

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of high-quality 【Zirconium Alloy Crucibles】. Our expertise in non-ferrous metal processing, coupled with our state-of-the-art facilities in Baoji, China's "Titanium Valley," allows us to deliver superior products that meet the most demanding industry standards. With our commitment to quality, customization capabilities, and global reach, we're your trusted partner for all your zirconium alloy needs.

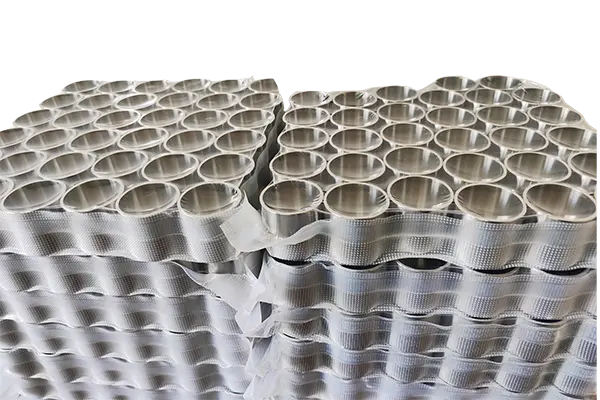

Zirconium Alloy Crucible picture display

|

|

|

Technical Specifications

- Material: High-purity zirconium alloys (Zr702, Zr704, Zr705)

- Temperature resistance: Up to 2400°C (4352°F)

- Sizes: Custom dimensions available (standard sizes from 5mm to 500mm diameter)

- Wall thickness: 1mm to 10mm (customizable)

- Purity: 99.2% (higher purity available upon request)

- Surface finish: As-cast or machined to specification

Key Features and Benefits

- Superior corrosion resistance against most acids and alkalis

- Excellent thermal stability and low thermal expansion

- High strength-to-weight ratio

- Non-magnetic properties

- Low neutron absorption cross-section

- Biocompatibility for medical applications

- Long service life and cost-effectiveness

Applications and Industries Served

Our 【Zirconium Alloy Crucibles】 find applications in various high-tech sectors, including:

- Nuclear energy and research

- Semiconductor manufacturing

- Advanced ceramics production

- Specialty chemical processing

- Medical and pharmaceutical industries

- Optical fiber production

Manufacturing Process

We employ advanced manufacturing techniques to ensure the highest quality:

- Raw material selection and testing

- Precision casting or forging

- Heat treatment for optimal microstructure

- CNC machining for exact dimensions

- Surface finishing and polishing

- Final inspection and quality control

Quality Control and Testing

Our rigorous quality control process includes:

- X-ray fluorescence (XRF) analysis for material composition

- Ultrasonic testing for structural integrity

- Dimensional accuracy checks

- Helium leak testing for sealed crucibles

- Surface roughness measurements

- Thermal cycling tests for stress resistance

Packaging and Shipping

We ensure safe delivery of your 【Zirconium Alloy Crucibles】 through:

- Custom-designed protective packaging

- Vacuum-sealed bags for moisture protection

- Shock-absorbing materials for transit safety

- Wooden crates for large shipments

- Comprehensive shipping documentation

- Flexible shipping options (air, sea, or express courier)

Why Choose Us

- Expertise in zirconium alloy processing

- Customization capabilities to meet your specific needs

- Strict quality control and compliance with international standards

- Quick response times and excellent customer service

- Competitive pricing and on-time delivery

- Long-term partnerships with global clients

OEM & Customization Services

We offer full OEM/ODM services, including:

- Custom alloy formulations

- Unique crucible designs and dimensions

- Special surface treatments or coatings

- Integration of additional features (e.g., pouring spouts, handles)

- Prototype development and small batch production

Certifications and Compliance

Our 【Zirconium Alloy Crucibles】 meet or exceed industry standards:

- ISO 9001:2015 Quality Management System

- ASTM B550 for zirconium and zirconium alloy ingots

- RoHS and REACH compliance

Customer Reviews and Case Studies

"Baoji Freelong's zirconium crucibles have significantly improved our semiconductor production process. Their custom designs and excellent quality control have made them an invaluable partner." - Leading Semiconductor Manufacturer, USA

"We've been using Freelong's crucibles in our nuclear research facility for over five years. Their products consistently meet our strict specifications and have never let us down." - Nuclear Research Institute, Europe

FAQs

Q: What is the typical lead time for custom 【Zirconium Alloy Crucibles】?

A: Lead times vary based on specifications, but we generally deliver within 4-6 weeks for custom orders.

Q: Can you provide material certificates for traceability?

A: Yes, we provide full material certifications and traceability documentation with every order.

Q: Do you offer sample crucibles for testing?

A: Absolutely! We can provide sample crucibles for your evaluation before larger orders.

Q: What is the minimum order quantity (MOQ)?

A: Our MOQ varies depending on the product specifications. Please contact us for details.

Q: Can you help with crucible design optimization?

A: Yes, our engineering team can assist in optimizing your crucible design for maximum performance and efficiency.

Contact Information

Ready to experience the superior quality of our 【Zirconium Alloy Crucibles】? Contact us today!

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Let Baoji Freelong be your trusted partner in high-performance zirconium alloy solutions. Reach out now to discuss your specific requirements and discover how we can elevate your operations with our top-tier products and services.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745716446475.webp)

_1745897261591.webp)

_1744361865881.webp)

_1745829389116.webp)