- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

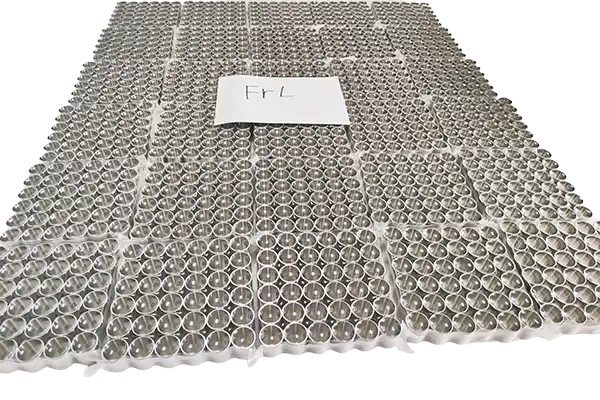

Zirconium Crucible Ø55mm With Smooth Interior

Brand: FRL Metal

Grade: Zr702,Zr705,R60001,R60901

Volume:5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc,

Type: Low form zirconiu crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible

Surface: polished surface

Density: 6.51g/cm3

Minimum Order Quantity:1pc

Sample: available

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Zirconium Crucible Ø55mm With Smooth Interior: Precision-Engineered for High-Purity Processing

At Baoji Freelong New Material Technology Development Co., Ltd., we take pride in manufacturing top-quality 【Zirconium Crucible Ø55mm With Smooth Interior】 solutions. Our advanced processing capabilities and years of experience in rare metals position us as a leading supplier for industries demanding the highest standards. With our smooth interior design and precise Ø55mm specifications, these crucibles offer unparalleled performance for your most critical applications.

Zirconium Crucible Ø55mm With Smooth Interior picture display

|

|

|

Product Introduction

Our 【Zirconium Crucible Ø55mm With Smooth Interior】 is the ideal choice for professionals in semiconductor manufacturing, advanced materials research, and high-temperature chemical processing. Engineered for exceptional purity and durability, this crucible meets the exacting needs of industries where contamination control and thermal stability are paramount.

Technical Specifications:

- Diameter: 55mm (±0.1mm tolerance)

- Material: High-purity zirconium (99.9% min.)

- Interior Finish: Mirror-smooth (<0.4μm Ra)

- Max Operating Temperature: 1800°C

- Corrosion Resistance: Excellent against most acids and alkalis

- Thermal Shock Resistance: Superior

Key Features and Benefits:

- Ultra-Smooth Interior: Minimizes material adhesion and enhances purity of processed materials.

- Precision Diameter: Ensures consistent fit and optimal performance in standardized equipment.

- High-Purity Zirconium Construction: Provides excellent chemical inertness and high-temperature stability.

- Exceptional Durability: Withstands repeated thermal cycling and aggressive chemical environments.

- Low Contamination Risk: Ideal for processes requiring ultra-high purity standards.

Applications and Industries Served:

- Semiconductor crystal growth

- High-temperature metal alloy refining

- Advanced ceramics production

- Nuclear fuel processing

- Chemical vapor deposition (CVD)

- Specialized laboratory research

Manufacturing Process:

Our 【Zirconium Crucible Ø55mm With Smooth Interior】 undergoes a rigorous production process:

- Raw material selection and testing

- Precision casting and forming

- CNC machining for exact dimensions

- Advanced polishing techniques for interior smoothness

- Ultrasonic cleaning and contaminant removal

- Final inspection and quality assurance

Quality Control and Testing:

Every crucible undergoes:

- Dimensional accuracy verification

- Surface roughness measurements

- Chemical composition analysis

- Thermal cycling tests

- Hydrostatic pressure testing

- Visual and microscopic inspections

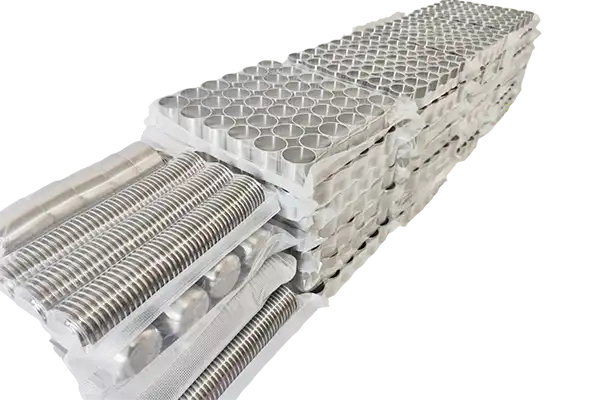

Packaging and Shipping:

- Individual foam-lined protective cases

- Vacuum-sealed in inert gas atmosphere

- Shock-absorbing outer packaging

- Express shipping options available worldwide

- Full tracking and insurance provided

Why Choose Us:

- Industry-leading expertise in zirconium processing

- Customization capabilities to meet unique specifications

- Rigorous quality control exceeding industry standards

- Responsive technical support and customer service

- Competitive pricing without compromising on quality

- Fast turnaround times and reliable delivery

OEM & Customization Services:

We offer full customization options for our 【Zirconium Crucible Ø55mm With Smooth Interior】, including:

- Custom dimensions and shapes

- Specialized coatings or surface treatments

- Integration of additional features (e.g., pouring spouts, handles)

- Material grade adjustments for specific applications

Certifications and Compliance:

- ISO 9001:2015 Quality Management System

- RoHS Compliant

- ASTM B550 Standard for Zirconium and Zirconium Alloy Ingots

- Adherence to SEMI standards for semiconductor industry

Customer Reviews and Case Studies:

"The smooth interior of Freelong's zirconium crucibles has significantly improved our crystal growth yields. A game-changer for our R&D efforts." - Dr. Sarah Chen, Advanced Materials Research Institute

"We've seen a 30% reduction in contamination levels since switching to Freelong's Ø55mm crucibles. Their precision and quality are unmatched." - John Smith, Quality Manager at TechSemi Inc.

FAQs:

- What makes your 【Zirconium Crucible Ø55mm With Smooth Interior】 unique?

Our crucibles feature an ultra-smooth interior finish and precise dimensions, ensuring minimal contamination and optimal performance in high-purity applications. - How long can I expect these crucibles to last?

With proper care, our zirconium crucibles can withstand hundreds of thermal cycles, often lasting several years in typical laboratory or production environments. - Are custom sizes available?

Yes, we offer full customization services to meet your specific requirements. Contact us for details on custom dimensions or features. - What's the lead time for orders?

Standard sizes are typically available within 2-3 weeks. Custom orders may require 4-6 weeks, depending on specifications. - Do you provide technical support for integration and use?

Absolutely. Our team of experts is available to assist with implementation, troubleshooting, and best practices for maximizing crucible performance.

Contact Information:

Ready to elevate your high-purity processing capabilities? Contact us today to discuss how our 【Zirconium Crucible Ø55mm With Smooth Interior】 can meet your precise needs.

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Experience the Freelong difference – where precision meets purity in every crucible we craft.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745572620134.webp)

_1744874965770.webp)

_1745219223121.webp)

_1747983195995.webp)