- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ASTM B551 Zirconium And Zircnoium Alloy Plate

Brand: FRL metal

Advantages: corrosion resistance, high temperature resistance

Grades: R60700, R60702, R60704, R60705,...

Product description

The performance of zirconium in organic acid is better than that of stainless steel, nickel alloy and titanium. This alloy is considered for these applications at high temperatures, and its remarkable advantages lead to clear economical advantages. Zirconium has poor resistance to concentrated sulfuric acid, hydrofluoric acid, concentrated phosphoric acid, ferric chloride, copper chloride, wet chlorine, and other oxidizing chloride environments. Zirconium plates also have a very high melting point, melting at only 1,855°C. Therefore, while many other metals are completely liquid, pure zirconium plate remains solid, making it ideal for use in high temperature environments.

Picture display

Advantages of Zirconium

No single metal or alloy is resistant to corrosion in all chemical environments. Zirconium is no exception, but it does have excellent resistance to a wide range of chemicals. Zirconium has outstanding resistance to alkaline media such as hydrochloric acid, sulfuric acid, organic acids and sodium hydroxide. Its resistance to nitric acid is only comparable to noble metals such as tantalum.

The most common areas of application for cast zirconium equipment are hydrochloric, sulfuric and hot organic acids. Zirconium exhibits excellent corrosion resistance to all concentrations of hydrochloric acid, even at temperatures above the normal boiling point. However, zirconium is not resistant to oxidizing substances containing hydrochloric acid such as copper chloride, ferric chloride or wet chlorine. Zr 702C is resistant to sulfuric acid concentrations up to 70% and Zr 705C is resistant to concentrations up to 55% of the normal boiling point of sulfuric acid. Even at room temperature, the higher the concentration, the worse the resistance.

Zirconium outperforms stainless steel, nickel alloys and titanium in organic acids. This alloy is considered for these applications at high temperatures, and its remarkable advantages lead to clear economical advantages. Zirconium has poor resistance to concentrated sulfuric acid, hydrofluoric acid, concentrated phosphoric acid, ferric chloride, copper chloride, wet chlorine, and other oxidizing chloride environments.

Zirconium plates also have a very high melting point, melting at only 1,855°C. Therefore, while many other metals are completely liquid, pure zirconium plate remains solid, making it ideal for use in high temperature environments.

FAQ

Q: What is the advantage of your company?

A: We have many professional technicians. We have more competitive price and better after-sales service than other companies.

Q:Can you provide samples? MOQ?

A:Yes, we can provide you with free samples. MOQ: 1 kg.

Q:Do you accept customization?

A:Yes, we can process according to your unit weight or drawing.

Q:Do you inspect the finished products?

A:Yes, every product will be inspected by our QC before shipment.

Our Packaging

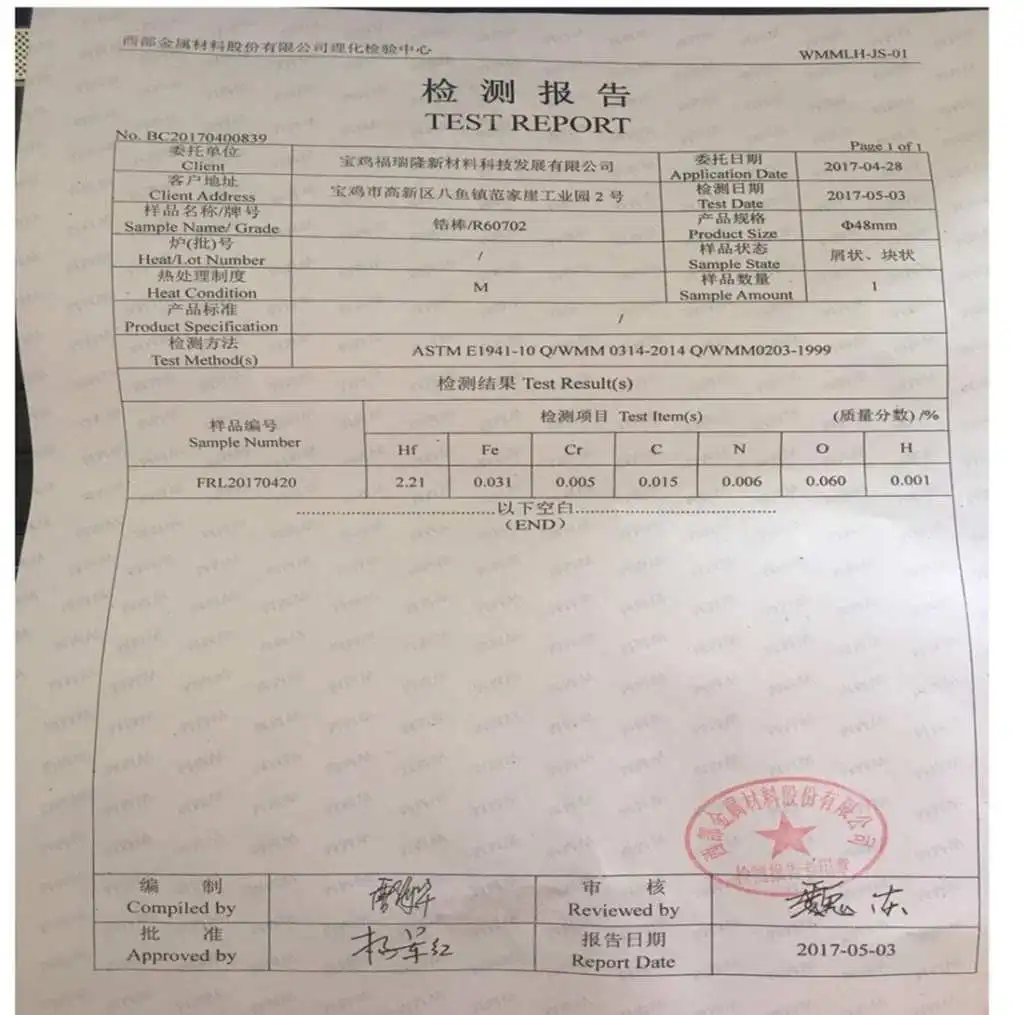

Testing Report

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum,Tungsten,Molybdenum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1744601338161.webp)

_1745897376668.webp)

_1745390650457.webp)

_1745737142626.webp)