- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

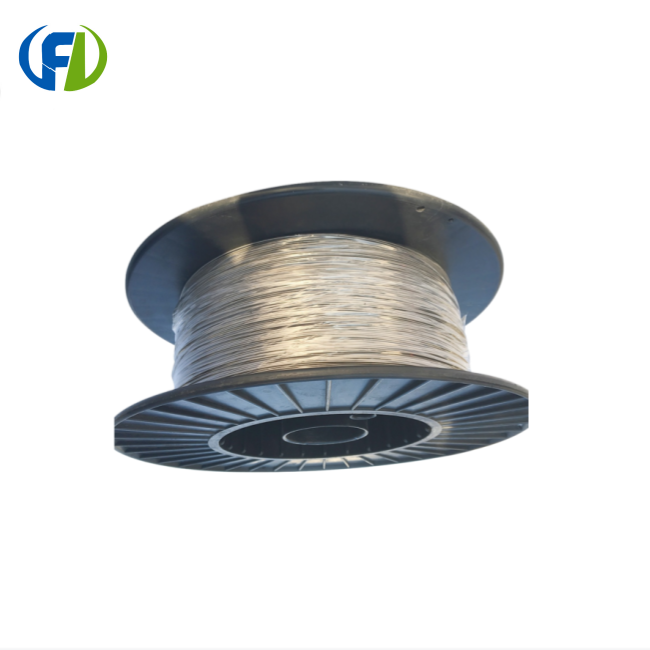

705 Zirconium Rod

Brand: FRL Metal

Grade: Zr60705

Density: 6.51g/cm3

Purity: >99.7%

Standard: ASTM B550

Certification: ISO 9001

Delivery time: 7- 15 days

Express: Fedex, TNT, DHL and EMS shipping

705 zirconium rods have the following main uses:

Chemical equipment: The corrosion resistance of 705 zirconium rod makes it an ideal material for chemical equipment manufacturing. It can be used to manufacture equipment such as storage tanks, heat exchangers, reactors and pipelines, which can operate safely under various corrosive media.

Marine engineering: 705 zirconium rods have excellent corrosion resistance in marine environments, so they are widely used in the field of marine engineering. It can be used to manufacture seawater treatment equipment, offshore platforms, ship accessories, etc., and can effectively resist corrosion and erosion in seawater.

Petroleum industry: Due to its good resistance to acidic and high temperature environments, 705 zirconium rods are widely used in the petroleum industry. It can be used to manufacture oil well equipment, oil and gas pipelines, oil well casing, etc., and can run stably for a long time in the harsh oil field environment.

705 Zirconium Rod Description

Because of its corrosion resistance and electrical conductivity, zirconium products are mainly used in industries such as the chemical and electronic industries.

Zirconium has a wide range of applications, mainly in the form of zirconium silicate and zirconium oxide in ceramics, refractories and other fields. Only 3%-4% of zirconium ore is processed into metal zirconium (or sponge zirconium), which is further processed into various zirconium materials. Due to the small thermal neutron absorption cross section of metal zirconium, metal zirconium has excellent nuclear properties. Shell etc. Nuclear grade zirconium can be regarded as an important strategic metal for the country and is closely related to the development of the nuclear industry.

What are the advantages of 705 zirconium rods?

Good corrosion resistance: 705 zirconium rod is a material with excellent corrosion resistance. It can resist the erosion of acid, alkali, salt and other corrosive media, and is not easily damaged by corrosion. This enables the 705 zirconium rod to operate stably for a long time in many corrosive environments, prolonging the service life of the equipment.

High strength: 705 zirconium rods have high strength and hardness, and can withstand certain mechanical loads and impact loads. This makes it useful in engineering for parts and devices that need to withstand high strength demands.

Good high-temperature performance: 705 zirconium rods have good high-temperature stability and can work in high-temperature environments without losing their mechanical properties and corrosion resistance. This gives 705 zirconium rods an important advantage in high temperature processes and applications.

Lightweight: Zirconium alloy is a lightweight material with a low relative density. Compared with other common metal materials such as steel, copper, etc., 705 zirconium rod has a lighter weight, which makes it very useful in occasions where equipment weight needs to be reduced, such as in the aerospace field.

Good thermal conductivity: 705 zirconium rod has good thermal conductivity, which can effectively transfer and dissipate heat, and improve the thermal stability and heat dissipation effect of the equipment.

705 Zirconium Rod picture display

|

|

|

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail: jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1767857938400.png)

_1747987650698.webp)

_1744853844074.webp)