- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

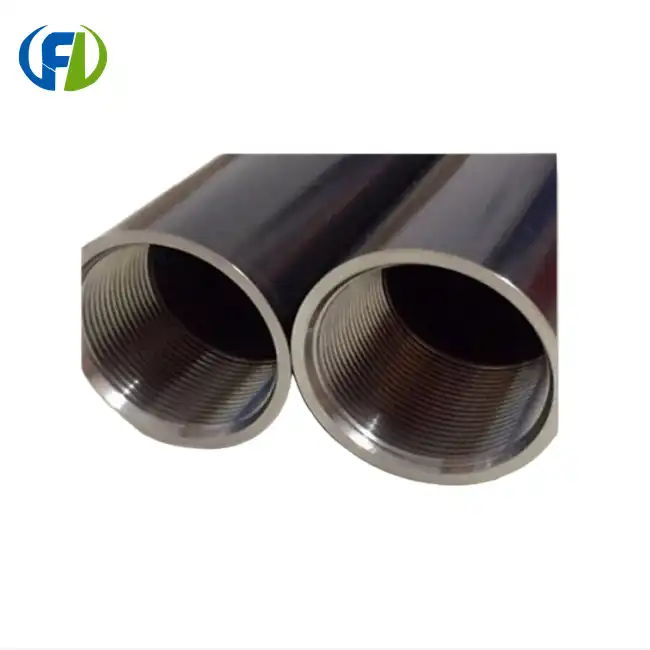

zirconium rod

Brand: FRL Metal

Grade: Zr702, Zr705, RO60804, RO60001,RO60901

Density: 6.51g/cm3

Standard: ASTM B550

Purity: >99.7%

Diameter: 2-100mm

Length: <12000mm

Packing: inner vacuum packing, outer plywood box

Certification: ISO 9001:2015

Delivery time: 7- 15 days

Express: Fedex, TNT, DHL and EMS shipping

Zirconium Rods: High-Performance Materials for Advanced Industries

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of high-quality zirconium rods. With our advanced processing capabilities and years of experience, we offer superior zirconium rods that meet the stringent requirements of various industries. Our commitment to excellence, customization options, and global market presence make us your ideal partner for all your zirconium needs.

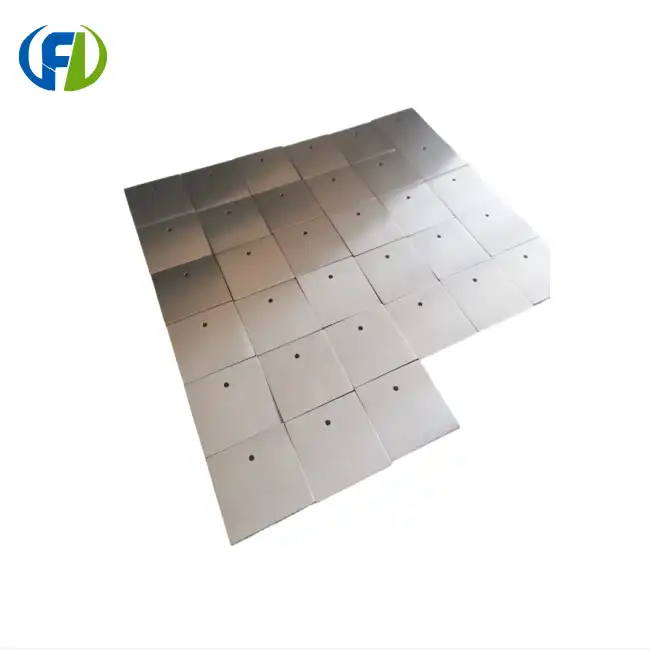

zirconium rod picture display

|

|

|

Product Introduction

Our zirconium rods are engineered to deliver exceptional performance in demanding applications. These versatile materials offer a unique combination of corrosion resistance, high-temperature strength, and excellent biocompatibility. Whether you're in the nuclear energy, chemical processing, aerospace, or medical device industry, our zirconium products are designed to meet your specific needs.

Technical Specifications

- Purity: 99.2% to 99.8%

- Diameter range: 3mm to 200mm

- Length: Custom lengths available

- Alloy options: Pure zirconium, Zircaloy-2, Zircaloy-4, and custom alloys

- Surface finish: As-rolled, ground, or polished

- Mechanical properties: Tensile strength, yield strength, and elongation tailored to customer requirements

Key Features and Benefits

- Exceptional corrosion resistance in harsh environments

- High strength-to-weight ratio for efficient designs

- Excellent neutron transparency for nuclear applications

- Biocompatible for medical implants and devices

- Low thermal expansion for stable performance

- Customizable dimensions and properties to suit specific needs

Applications and Industries Served

Our zirconium rods find applications across various high-tech industries:

- Nuclear Energy: Fuel rod cladding, reactor components

- Chemical Processing: Pumps, valves, heat exchangers

- Aerospace: Engine components, structural parts

- Medical Devices: Implants, surgical instruments

- Electronics: Sputtering targets, semiconductor manufacturing

Manufacturing Process

We employ state-of-the-art manufacturing techniques to ensure the highest quality:

- Raw material selection and testing

- Melting and ingot formation

- Hot working and cold working processes

- Heat treatment for optimal properties

- Precision machining and finishing

- Rigorous quality control at each stage

Quality Control and Testing

Our commitment to quality is unwavering:

- 100% material traceability

- In-house laboratory for chemical and mechanical testing

- Non-destructive testing (NDT) for internal defects

- Dimensional inspection using advanced measurement tools

- Compliance with ASTM, ASME, and other international standards

Packaging and Shipping

We ensure safe delivery of your zirconium rods:

- Custom packaging options to prevent damage

- Secure crating for international shipments

- Full documentation and certification

- Flexible shipping methods to meet your timeline

Why Choose Us

- Extensive experience in zirconium processing

- Customization capabilities to meet unique specifications

- Strict quality control measures

- Competitive pricing and reliable delivery

- Excellent customer support and technical assistance

OEM & Customization Services

We specialize in tailoring our zirconium rods to your exact requirements:

- Custom alloy compositions

- Specific dimensions and tolerances

- Special surface treatments or coatings

- Prototype development and small batch production

Certifications and Compliance

Our operations and products meet rigorous industry standards:

- ISO 9001:2015 certified quality management system

- ASTM and ASME material compliance

- RoHS and REACH compliant for environmental safety

- Nuclear-grade certifications for reactor components

Customer Reviews and Case Studies

"Baoji Freelong's zirconium rods have consistently met our strict quality standards for nuclear applications. Their technical support and on-time delivery are outstanding." - Leading Nuclear Energy Company

"We've relied on Freelong's custom zirconium alloys for our chemical processing equipment. Their products have significantly extended the lifespan of our reactors." - Global Chemical Manufacturer

FAQs

Q: What is the minimum order quantity for zirconium rods?

A: We can accommodate both small and large orders. Please contact us for specific requirements.

Q: Can you provide material certificates with each order?

A: Yes, we provide full material certifications and test reports with every shipment.

Q: What is the typical lead time for custom zirconium rods?

A: Lead times vary based on specifications and quantity. Generally, we can deliver within 4-8 weeks for custom orders.

Q: Do you offer samples before bulk orders?

A: Yes, we can provide samples for testing and approval before large-scale production.

Trust Baoji Freelong New Material Technology Development Co., Ltd. for all your zirconium needs. Let's innovate together!

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745485194426.webp)

_1744959568232.webp)