- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Zr702 Zirconium Tube

Brand: FRL Metal

Grade: Zr702

Density: 6.51g/cm3

Surface: Bright

Shape: Customizable

Packing details: Plywood box

Export port: Any port in China

Certification: ISO 9001

Express: FedEx, TNT, DHL and EMS shipping

Product description of Zr702 zirconium tube

Zr702 zirconium tube is an alloy tubular material made of metal zirconium and other metals. Due to the excellent properties and corrosion resistance of zirconium, zirconium alloy tubes are often used in fuel assemblies and internal structures of water-cooled reactors, and are important materials. Pure zirconium tubes are mainly used to manufacture chemical equipment, because they are expensive and not much used. The chemical composition of the commonly used zirconium tubes and their uses are shown in the table, among which the amount of zirconium-tin alloy tubes and rods is more.

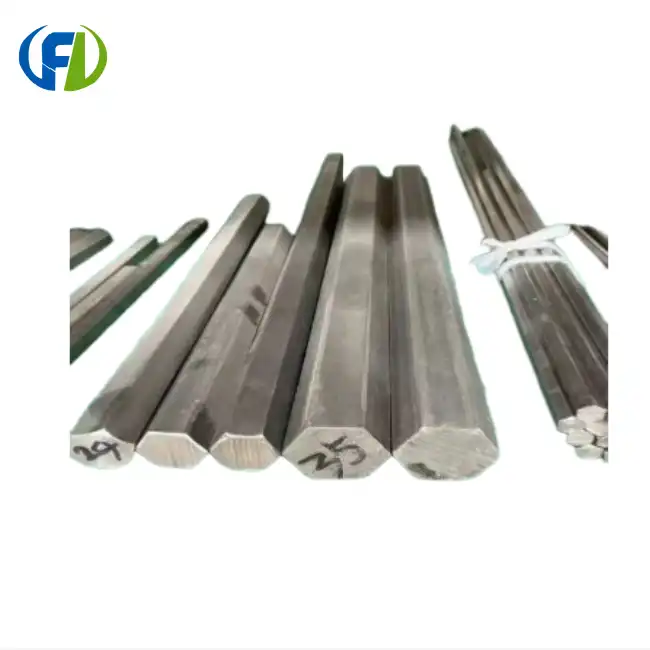

Zr702 Zirconium Tube picture display

|

|

|

Zr702 Zirconium Tube Chemical Composition Requirements

| Element | ASTM B523 / B658 Seamless & Welded Pipe and Tubes | ||

| R60702 | R60704 | R60705 | |

| Zirconium(+Hf) | ≥99.2 | ≥97.5 | ≥95.5 |

| Hafnium | ≤4.5 | ≤4.5 | ≤4.5 |

| Iron+Chromium | ≤0.2 | 0.2~0.4 | ≤0.2 |

| Tin | - | 1.0~2.0 | - |

| Hydrogen | ≤0.005 | ≤0.005 | ≤0.005 |

| Nitrogen | ≤0.025 | ≤0.025 | ≤0.025 |

| Carbon | ≤0.05 | ≤0.05 | ≤0.05 |

| Niobium | - | - | 2.0~3.0 |

| Oxygen | ≤0.16 | ≤0.18 | ≤0.18 |

ZR702 ZIRCONIUM TUBE Mechanical Properties Requirements

| ASTM B550/B658 | Tensile Strength, min. | Yield Strength, min | Elongation | ||

| Grade | ksi | MPa | ksi | MPa | min. % |

| R60702 | 55 | 380 | 30 | 205 | 16 |

| R60704 | 60 | 415 | 35 | 240 | 14 |

| R60705 | 80 | 550 | 55 | 380 | 16 |

Process characteristics of Zr702 zirconium tube

(1) Zirconium has a strong affinity with gas. It reacts with oxygen, hydrogen and nitrogen at about 200, 300 and 400 °C, respectively. The reaction is rapid at higher temperatures, so casting and heat treatment must be carried out in a vacuum furnace. When hot working in the atmosphere, proper protection should be taken and the operating time at high temperature should be shortened.

(2) The friction coefficient between zirconium and the mold is high, and it is easy to adhere to the surface of the mold; the thermal effect of plastic deformation is good, and good lubrication conditions are required during processing.

(3) The processing specification has a more sensitive influence on the performance of the product. Special attention should be paid to controlling the cold working and heat treatment process before the finished product to meet the requirements of use.

(4) The dimensional accuracy and surface quality of the pipe and bar are very high. Therefore, the process equipment should have good precision, and the tooling and mold design and production should be reasonable.

|

Grade |

R60702 |

|

Standard |

ASTM B523 |

|

Applications |

Chemical processing, medical instruments etc. Aerospace, Industry, Navigation, Smelting, Chemical plants, and so on. |

|

Packaging |

Standard export plywood case or as per order |

|

Payment |

T/T.L/C,Western union, PayPal. Prepaid30% T/T against PI, pay for balance before delivery. |

|

Delivery time |

Within 7-15 days after you confirmed. |

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745487678013.webp)

_1744358111987.webp)

_1768468411457.png)