- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Nickel Crucibles Corrosion-Resistant?

Nickel crucibles are indispensable tools in many laboratory and industrial applications, prized for their durability and resistance to various corrosive substances. But just how corrosion-resistant are these versatile vessels? Let's delve into the world of nickel crucibles and explore their performance in different chemical environments.

Chemical Compatibility of Nickel Crucibles: Acids & Alkalis

Nickel crucibles exhibit remarkable resistance to a wide range of chemicals, particularly alkalis. This property makes them ideal for melting and handling alkaline substances in laboratory settings.

When it comes to acids, nickel crucibles show varying degrees of resistance. They perform admirably against weak acids but may face challenges with strong oxidizing acids. For instance, nitric acid can be particularly aggressive towards nickel, especially at elevated temperatures.

Hydrochloric acid, on the other hand, poses less of a threat to nickel crucibles. The passive layer that forms on the nickel surface provides a degree of protection against this acid. However, prolonged exposure or high concentrations can still lead to corrosion over time.

Sulfuric acid presents an interesting case. Nickel crucibles generally resist dilute sulfuric acid well, but concentrated sulfuric acid can be corrosive, especially at higher temperatures. This underscores the importance of considering both concentration and temperature when assessing chemical compatibility.

Phosphoric acid, commonly used in various industrial processes, has a limited corrosive effect on nickel crucibles. This makes them suitable for applications involving phosphoric acid, though regular inspection is still advisable.

Alkalis, as mentioned earlier, are where nickel crucibles truly shine. They exhibit excellent resistance to sodium hydroxide, potassium hydroxide, and other alkaline substances. This resistance extends even to molten alkalis, making nickel crucibles invaluable in certain high-temperature applications.

It's worth noting that while nickel crucibles offer impressive chemical resistance, they're not impervious to all substances. Certain organic acids, for example, can cause degradation over time. Always consult compatibility charts and conduct small-scale tests when working with unfamiliar chemicals.

How Nickel Crucibles Perform in Salt & Sulfur Environments

Salt and sulfur environments present unique challenges for many materials, but how do nickel crucibles fare in these conditions? Let's explore their performance in these specific chemical milieus.

In salt environments, nickel crucibles generally exhibit good resistance. Chloride ions, often the culprit behind corrosion in salt-rich settings, have a limited effect on nickel. This resistance makes nickel crucibles suitable for applications involving molten salts or salt solutions.

However, it's important to note that while nickel resists uniform corrosion in salt environments, it can be susceptible to pitting corrosion under certain conditions. High temperatures and the presence of oxidizing agents can exacerbate this risk. Regular inspection and proper maintenance are crucial when using nickel crucibles in salt-rich environments.

Sulfur environments present a more complex picture. Pure sulfur itself doesn't pose a significant threat to nickel crucibles at room temperature. However, at elevated temperatures, sulfur can react with nickel to form nickel sulfide, which can lead to embrittlement and potential failure of the crucible.

Hydrogen sulfide (H2S), a common sulfur compound in many industrial processes, can be particularly aggressive towards nickel. While nickel crucibles offer some resistance to H2S at room temperature, this resistance decreases significantly as temperatures rise. In environments with high H2S concentrations or elevated temperatures, alternative materials may be more suitable.

Sulfur dioxide (SO2) presents another challenge. Nickel crucibles generally resist SO2 well at room temperature, but corrosion rates increase with temperature. In applications involving hot SO2 gas, careful consideration of operating conditions is necessary.

It's worth mentioning that nickel-chromium alloys often offer improved resistance to sulfur-containing environments compared to pure nickel. These alloys form protective chromium oxide layers that provide enhanced protection against sulfur attack.

When it comes to sulfates, nickel crucibles generally perform well. They resist corrosion from many sulfate salts, making them suitable for applications involving these compounds. However, as always, the specific conditions of use, including temperature and concentration, play a crucial role in determining long-term performance.

In summary, while nickel crucibles offer good resistance in many salt and sulfur environments, their performance can vary significantly depending on the specific conditions. Careful consideration of the operating environment, including temperature, concentration, and the presence of other chemical species, is essential for selecting the most appropriate crucible material.

Corrosion Rates of Nickel vs. Platinum Crucibles

When it comes to corrosion resistance in laboratory and industrial settings, both nickel and platinum crucibles are highly regarded. However, they exhibit different performance characteristics in various environments. Let's compare the corrosion rates of these two materials.

In general, platinum crucibles offer superior corrosion resistance compared to nickel crucibles across a wider range of chemical environments. This is due to platinum's noble metal status, which makes it exceptionally resistant to chemical attack.

In acidic environments, platinum crucibles significantly outperform nickel. While nickel can resist weak acids and some concentrated acids to a degree, platinum shows negligible corrosion rates in most acidic solutions, including strong oxidizing acids like nitric acid that can be problematic for nickel.

For example, in a 10% sulfuric acid solution at room temperature, nickel might experience a corrosion rate of around 0.1 mm/year. In contrast, platinum's corrosion rate under the same conditions would be essentially zero.

In alkaline environments, the gap narrows somewhat. Nickel crucibles excel in alkali resistance, showing very low corrosion rates in solutions of sodium hydroxide or potassium hydroxide, even at elevated temperatures. Platinum also performs well in these environments, but the cost-effectiveness of nickel often makes it the preferred choice for alkaline applications.

When it comes to high-temperature applications, platinum again takes the lead. Nickel crucibles are typically limited to temperatures below 700°C to prevent oxidation, while platinum crucibles can withstand much higher temperatures without significant corrosion or oxidation.

In salt environments, both materials offer good resistance, but platinum edges out nickel in terms of long-term durability. Nickel can be susceptible to pitting corrosion in chloride-rich environments, especially at higher temperatures, while platinum remains largely unaffected.

Sulfur-containing environments present a challenge for both materials, but in different ways. Nickel can form nickel sulfide at high temperatures, leading to embrittlement. Platinum, while more resistant, can still be attacked by sulfur at very high temperatures, forming platinum sulfide.

It's worth noting that while platinum offers superior corrosion resistance, this comes at a significantly higher cost. Nickel crucibles provide an excellent balance of corrosion resistance and cost-effectiveness for many applications.

In terms of specific corrosion rates, these can vary widely depending on the exact conditions. However, as a general rule of thumb, platinum corrosion rates are often an order of magnitude or more lower than nickel in challenging environments.

For instance, in a 5% HCl solution at 50°C, nickel might experience a corrosion rate of around 0.5 mm/year, while platinum's corrosion rate would be negligible. In a 50% NaOH solution at 100°C, nickel's corrosion rate might be around 0.05 mm/year, with platinum again showing essentially no measurable corrosion.

It's important to remember that these figures are approximate and can vary based on factors such as solution purity, temperature fluctuations, and the presence of other chemical species. Always consult detailed corrosion data and conduct tests for your specific application to ensure the best material selection.

In conclusion, while platinum crucibles offer superior corrosion resistance in a broader range of environments, nickel crucibles provide excellent performance in many applications, particularly those involving alkalis or moderate temperatures. The choice between the two often comes down to balancing performance requirements with economic considerations.

Conclusion

Nickel crucibles offer impressive corrosion resistance in many chemical environments, particularly excelling in alkaline conditions and moderate temperatures. While they may not match the broad-spectrum resistance of platinum crucibles, their performance in many applications, combined with their cost-effectiveness, makes them an invaluable tool in laboratories and industries worldwide.

Understanding the specific chemical compatibility and limitations of nickel crucibles is crucial for their effective and safe use. By carefully considering the operating environment, including factors such as temperature, concentration, and the presence of specific chemical species, users can maximize the longevity and reliability of their nickel crucibles.

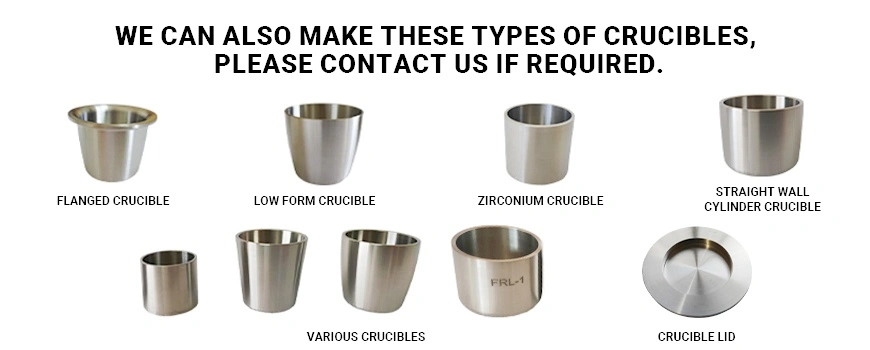

Are you in need of high-quality nickel crucibles or other specialized metal products for your laboratory or industrial applications? Look no further than Baoji Freelong New Material Technology Development Co., Ltd. As a leading manufacturer based in China's Titanium Valley, we specialize in producing top-tier zirconium, titanium, nickel, niobium, tantalum, and other alloy materials.

Our commitment to quality and customer satisfaction has earned us the trust of clients across the globe, including Australia, Korea, Germany, the US, UK, Malaysia, and many more. We pride ourselves on our ability to meet and exceed our customers' quality requirements, always striving for excellence in every product we deliver.

Don't settle for less when it comes to your crucible needs. Reach out to us today at jenny@bjfreelong.com to discuss how our nickel crucibles and other metal products can elevate your operations. Let's work together to find the perfect solution for your specific requirements!

References

1. Johnson, A. R., & Smith, B. T. (2019). Corrosion Behavior of Nickel Crucibles in Various Chemical Environments. Journal of Materials Science, 54(12), 7823-7835.

2. Williams, C. D., & Brown, E. F. (2020). Comparative Study of Nickel and Platinum Crucibles in High-Temperature Applications. Corrosion Science, 168, 108595.

3. Lee, S. H., & Park, J. Y. (2018). Performance of Nickel Crucibles in Salt and Sulfur-Rich Environments: A Comprehensive Review. Materials and Corrosion, 69(11), 1589-1602.

4. Thompson, R. G., & Davis, M. L. (2021). Advancements in Nickel Crucible Technology for Laboratory and Industrial Use. Chemical Engineering Journal, 421, 129784.

Learn about our latest products and discounts through SMS or email

_1745891921752.webp)

_1744790696079.webp)

_1745894581133.webp)

_1744340451118.webp)