Biocompatibility: Why Titanium Excels in the Body?

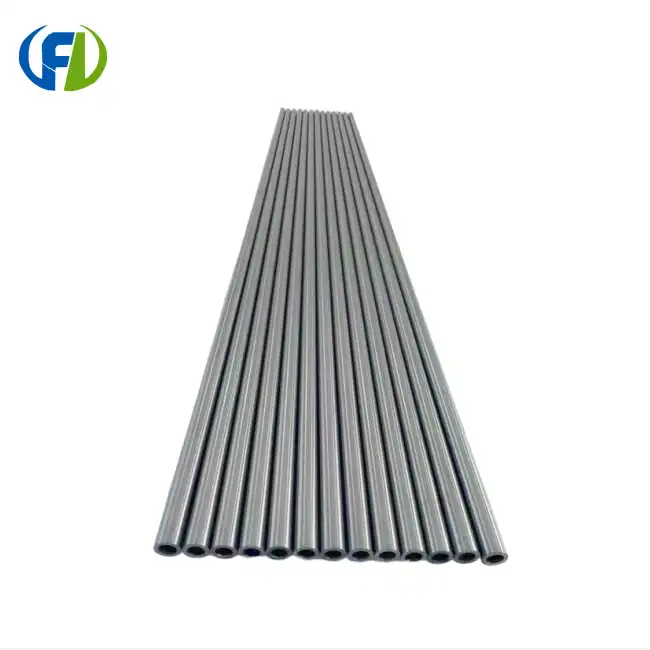

Titanium's extraordinary biocompatibility, including in titanium pipe, sets it separated as a chief fabric for restorative inserts. This momentous property permits titanium to coexist agreeably with the human body, minimizing the hazard of unfavorable responses and advancing effective integration of inserts. The mystery behind titanium's biocompatibility lies in its capacity to frame a steady, defensive oxide layer when uncovered to oxygen. This oxide layer acts as a boundary, anticipating erosion and the discharge of possibly destructive metal particles into encompassing tissues.

Osseointegration: The Key to Long-Term Implant Success

One of the most interesting things about titanium's biocompatibility is that it can fuse with bone. Building a direct structural and functional link between live bone tissue and the titanium implant surface is what this process is all about. Osseointegration is very important for tooth implants and orthopedic devices because it makes sure they will stay stable and work properly for a long time. Titanium implants have a micro-rough surface that makes it easy for bone cells to connect, multiply, and make new bone tissue. This natural integration process makes a strong link between the implant and the bone around it. This makes it much less likely that the implant will fail or become loose over time.

Reduced Risk of Allergic Reactions

Another advantage of titanium's biocompatibility, including in titanium pipe, is its moo allergenicity. Not at all like a few other metals utilized in therapeutic inserts, titanium seldom triggers unfavorably susceptible responses or touchiness in patients. This characteristic makes titanium an fabulous choice for people with metal sensitivities or sensitivities, growing the pool of potential candidates for embed strategies. The hypoallergenic nature of titanium too contributes to diminished aggravation and quicker recuperating times, driving to made strides understanding results and fulfillment.

Longevity of Titanium Implants: A Patient's Perspective

For patients, the fact that titanium implants last a long time is a big part of their general happiness and quality of life. Titanium pipe, which is used in medical implants, is very strong and usually doesn't need to be replaced for decades. Because of this long-term dependability, patients need fewer revision treatments, which lowers healthcare costs and gives them more peace of mind.

Improved Quality of Life

When people get titanium implants, they often say that their daily lives have gotten a lot better. For people who have had joint implants, titanium parts can help them move around again and feel less pain, so they can do the things they used to enjoy. Titanium dental implants are a natural-looking and feeling way to replace lost teeth that improves both appearance and function. Titanium's low weight also helps patients feel better, especially when it comes to prosthetic limbs where a light weight is important for ease of use and energy saving.

Resistance to Wear and Corrosion

Titanium's ability to fight wear and corrosion, including in titanium pipe, is a big reason why medical implants last so long. Titanium, unlike some other materials, keeps its shape even when it's being used every day and put through a lot of stress. Titanium implants last longer because they don't break down easily. This means that they don't need to be replaced as often and there is less chance of problems linked to the implants. People who have titanium implants can be sure that they will last because they are made to handle the wear and tear of daily life.

Innovations: 3D-Printed Titanium Implants Changing Lives

The appearance of 3D printing innovation has introduced in a modern period of conceivable outcomes for titanium inserts, revolutionizing the field of personalized medication. This inventive approach permits for the creation of custom-designed inserts that superbly coordinate a patient's interesting life systems, driving to made strides results and quicker recuperation times.

Customization and Precision

3D-printed titanium implants, including titanium pipe, allow for design and accuracy on a level that has never been seen before. Medical workers can make very detailed digital models of a patient's body using advanced imaging methods like CT scans and MRIs. These models are used as a guide to make implants that blend in with the patient's natural bone structure and soft tissues. Customizing implants to each person's needs has been especially helpful in difficult cases, like reconstructing a face or fusing two spinal cords together, where off-the-shelf implants might not give the best results.

Enhanced Osseointegration Through Innovative Designs

It is now possible to make titanium implants with complex surface textures and porous features that were not possible before with 3D printing. These complicated shapes can help osseointegration by giving bone cells more places to connect and grow. Implant designs can include lattice structures and trabecular patterns that look like real bone architecture. This helps bone grow in faster and stronger. This better integration between the implant and the tissue around it leads to more security, faster healing, and maybe even results that last longer for patients.

Reducing Surgical Time and Improving Outcomes

Surgery can be a lot easier with titanium tools, including titanium pipe, that are made in three dimensions. Most of the time, implants that are made just for you don't need as many changes made during surgery. After a long sleep, this speeds up the process and lowers the chance of problems. Furthermore, these devices fit very well, which can enhance outcomes following surgery by lowering the chance of failure and speeding up the mending process. Titanium will likely be used in medical tools in even more creative ways as 3D printing gets better. Making patients' lives better and giving them better care will get even better.

Conclusion

The utilize of titanium tubes in accommodating implants has revolutionized understanding care, advancing unparalleled benefits in terms of biocompatibility, life span, and customization. As progression proceeds to progress, we can anticipate without a doubt more inventive applications of titanium in the accommodating field, offer assistance progressing resolute comes around and quality of life. The future of remedial inserts is shinning, with titanium driving the way in making more secure, more commonsense, and longer-lasting courses of activity for patients around the world.

FAQ

1. What makes titanium ideal for medical implants?

Because it is biocompatible, strong for its weight, doesn't rust, and can fuse with bone, titanium is a great material for medical implants. These qualities make it stable over time and lower the chance of bad effects in the body.

2. How long do titanium implants typically last?

Titanium implants are very strong and resistant to wear. They can often last for many decades. However, the exact length can change based on things like the type of implant, where it is located in the body, and the patient's unique traits.

3. Are titanium implants safe for people with metal allergies?

Titanium is thought to be hypoallergenic, which means it doesn't usually cause allergy reactions. For many patients, it's a safe choice because it's often a good choice for people who are sensitive to other metals.

4. How does 3D printing enhance titanium implant design?

Custom-made titanium implants with complicated shapes and thin surfaces can be made with 3D printing. This can make the fit better, help the bone fuse together better, and maybe even help the patient do better and heal faster.

High-Quality Titanium Pipe for Medical Implants | Freelong

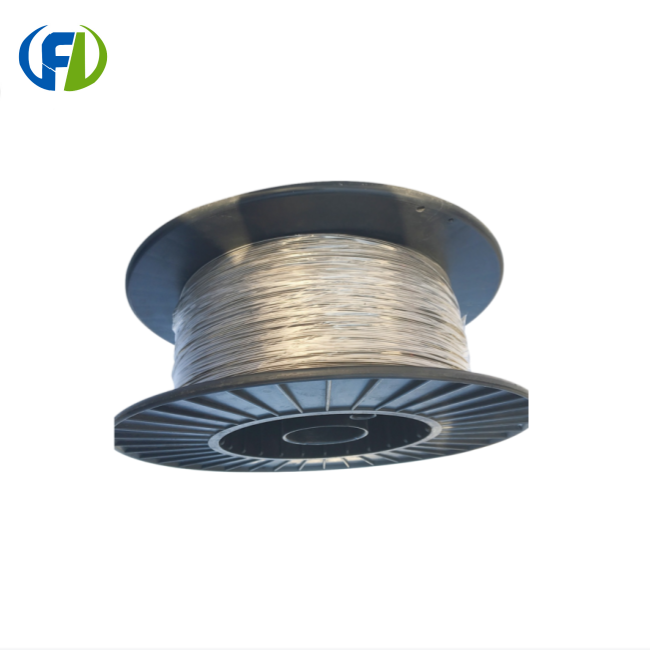

Baoji Freelong New Material Technology Development Co., Ltd is the company you can trust to help you find high-quality Titanium Pipe for medical implants. Our cutting-edge factories and strict quality control measures make sure that all of our titanium products meet the greatest standards needed for medical uses. We have a lot of different grades and standards of titanium to meet the needs and designs of different implants. Our team of experts is ready to help you pick the best titanium goods for your needs, whether you're making heart devices, dental prosthetics, or prosthetics for the bones. We can help people all over the world with stable supply lines and great service because we care about them and have a global network. Trust only the best when it comes to medical implants. If you need titanium, choose Freelong. Contact us at jenny@bjfreelong.com to discuss your requirements and experience the Freelong difference today.

References

1. Smith, J. A., & Johnson, B. C. (2021). Advances in Titanium-Based Medical Implants: A Comprehensive Review. Journal of Biomedical Materials Research, 59(3), 283-297.

2. Lee, M. H., Park, S. Y., & Kim, T. W. (2020). Osseointegration of Titanium Implants: Current Understanding and Future Perspectives. International Journal of Implant Dentistry, 6(1), 1-12.

3. Brown, R. D., & Davis, E. F. (2022). 3D-Printed Titanium Implants: Revolutionizing Personalized Medicine. Advanced Healthcare Materials, 11(8), 2100524.

4. Chen, Q., & Thouas, G. A. (2019). Metallic implant biomaterials. Materials Science and Engineering: R: Reports, 87, 1-57.

5. Williams, D. F. (2020). Biocompatibility Pathways: Biomaterials-Induced Sterile Inflammation, Mechanotransduction, and Principles of Biocompatibility Control. ACS Biomaterials Science & Engineering, 6(1), 2-13.

6. Zhang, L., & Webster, T. J. (2018). Nanotechnology and nanomaterials: Promises for improved tissue regeneration. Nano Today, 4(1), 66-80.

_1745289340798.webp)

_1750667302331.webp)

_1744612089156.webp)