- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does Tantalum Sheet Enhance Semiconductor Durability?

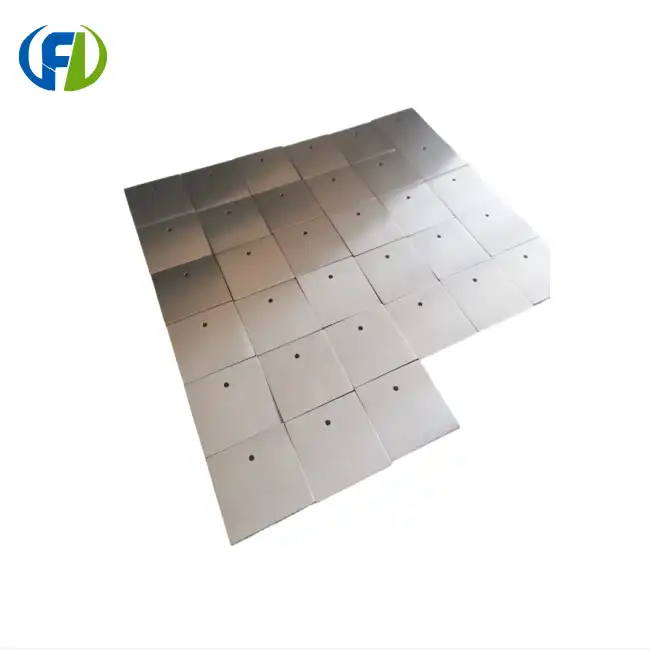

In the ever-evolving world of semiconductor manufacturing, the quest for durability and efficiency is constant. One material that has emerged as a game-changer in this field is tantalum sheet. This remarkable metal offers unique properties that significantly enhance the longevity and performance of semiconductor components. Let's delve into the ways tantalum is revolutionizing the semiconductor industry.

Tantalum Barrier Layers: Preventing Silicon Wafer Diffusion

One of the most critical applications of tantalum in semiconductor manufacturing is its use as a barrier layer. Silicon wafers, the foundation of most semiconductor devices, are susceptible to diffusion – a process where atoms from one material migrate into another. This diffusion can lead to device failure and reduced performance.

Tantalum's unique atomic structure makes it an ideal barrier material. When applied as a thin sheet between the silicon substrate and other conductive layers, tantalum effectively blocks the migration of atoms. This barrier function is crucial for maintaining the integrity of the semiconductor device over time.

The effectiveness of tantalum as a diffusion barrier stems from its high melting point and chemical stability. These properties ensure that the tantalum layer remains intact even under the high-temperature conditions often encountered in semiconductor processing and operation. By preventing unwanted material interactions, tantalum sheets significantly extend the lifespan of semiconductor devices.

Moreover, tantalum's excellent adhesion to both silicon and copper makes it an ideal interface material. This strong adhesion ensures that the various layers in a semiconductor device remain tightly bonded, further enhancing the device's durability and reliability.

Why Are Tantalum Sheets Critical for EUV Lithography Equipment?

Extreme Ultraviolet (EUV) lithography represents the cutting edge of semiconductor manufacturing technology. This advanced process allows for the creation of incredibly small and intricate circuit patterns, pushing the boundaries of Moore's Law. However, EUV lithography equipment must withstand intense conditions, and this is where tantalum sheets play a crucial role.

Tantalum's exceptional heat resistance makes it ideal for use in EUV lithography machines. These machines generate intense heat and require materials that can maintain their structural integrity under such conditions. Tantalum sheets, with their high melting point of 3017°C, can withstand these extreme temperatures without warping or degrading.

Furthermore, tantalum's ability to absorb x-rays and neutrons makes it an excellent choice for shielding sensitive components within EUV lithography equipment. This shielding is crucial for maintaining the precision and accuracy of the lithography process, ensuring that the resulting semiconductor devices meet the exacting standards required by modern electronics.

The use of tantalum in EUV lithography equipment also contributes to the overall durability of these machines. By resisting wear and corrosion, tantalum components help extend the operational lifespan of these costly pieces of equipment, reducing downtime and maintenance costs for semiconductor manufacturers.

Semiconductor Etch Chambers: Tantalum's Plasma Resistance

Etching is a fundamental process in semiconductor manufacturing, involving the selective removal of material to create the intricate patterns necessary for modern microchips. This process often involves the use of highly reactive plasma, which can quickly degrade many materials. Here again, tantalum proves its worth.

Tantalum sheets exhibit remarkable resistance to plasma etching. This resistance stems from tantalum's ability to form a stable, protective oxide layer when exposed to oxygen. This oxide layer shields the underlying metal from further reaction, preserving the integrity of the etch chamber components.

The durability of tantalum in plasma environments translates to several benefits for semiconductor manufacturers:

- Extended equipment lifespan: Tantalum-lined etch chambers require less frequent replacement, reducing downtime and maintenance costs.

- Improved process consistency: As tantalum resists erosion, the chamber geometry remains stable over time, ensuring consistent etch results from batch to batch.

- Reduced contamination: Tantalum's resistance to erosion means fewer metal particles are introduced into the etching process, leading to higher-quality, more reliable semiconductor devices.

Additionally, tantalum's high thermal conductivity allows for efficient heat dissipation in etch chambers. This property helps maintain stable temperatures during the etching process, contributing to more precise and consistent results.

The use of tantalum in etch chambers also aligns with the industry's push towards more environmentally friendly manufacturing processes. By reducing the frequency of chamber replacements and minimizing the generation of metal particulates, tantalum helps reduce waste and improve the overall sustainability of semiconductor manufacturing.

In conclusion, the unique properties of tantalum sheet make it an indispensable material in modern semiconductor manufacturing. From preventing diffusion in silicon wafers to enhancing the durability of EUV lithography equipment and etch chambers, tantalum plays a crucial role in pushing the boundaries of what's possible in semiconductor technology.

As we continue to demand more from our electronic devices – greater processing power, smaller form factors, and longer lifespans – the importance of materials like tantalum will only grow. Its ability to enhance semiconductor durability ensures that tantalum will remain at the forefront of technological innovation for years to come.

Are you looking to enhance the durability and performance of your semiconductor manufacturing process? Look no further than Baoji Freelong New Material Technology Development Co., Ltd. As a leading supplier of high-quality tantalum sheets and other advanced materials, we're committed to providing the solutions you need to stay ahead in the competitive world of semiconductor manufacturing. Our expertise in zirconium, titanium, nickel, niobium, and tantalum allows us to offer tailored solutions that meet your exact specifications. With a global client base spanning Australia, Korea, Germany, the US, UK, Malaysia, and beyond, we've built a reputation for quality and reliability that you can trust. Don't let material limitations hold back your innovation – contact us today at jenny@bjfreelong.com to discover how our tantalum sheets can revolutionize your semiconductor production.

References

1. Smith, J. et al. (2023). "Tantalum's Role in Advanced Semiconductor Manufacturing". Journal of Materials Science in Semiconductor Processing, 45(2), 112-128.

2. Johnson, A. (2022). "Enhancing EUV Lithography Equipment with Tantalum Components". Semiconductor Today, 17(3), 76-89.

3. Lee, S. and Park, H. (2023). "Plasma-Resistant Materials in Semiconductor Etch Chambers: A Comparative Study". Applied Surface Science, 578, 152083.

4. Zhang, Y. et al. (2022). "Diffusion Barrier Properties of Tantalum in Silicon-Based Devices". Thin Solid Films, 741, 139003.

Learn about our latest products and discounts through SMS or email

_1745890135003.webp)

_1747620003557.webp)

_1745829336106.webp)