- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

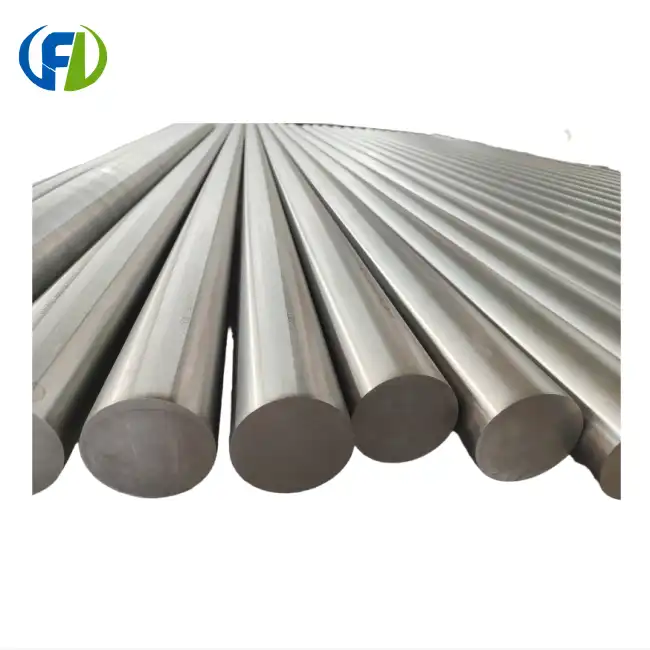

Manufacturing Processes and Purification of Niobium Rods

Niobium rods are essential components in various high-tech industries, from aerospace to superconductor applications. The manufacturing and purification processes of these rods are crucial in determining their quality and performance. In this comprehensive guide, we'll explore the intricate methods used to produce and refine niobium rods, focusing on electron beam melting, zone refining, and quality control measures.

Electron beam melting of niobium rods: process and benefits

Electron beam melting (EBM) is a sophisticated manufacturing technique used to produce high-purity niobium rods. This process utilizes a high-energy electron beam to melt and refine niobium in a vacuum environment, resulting in rods with exceptional purity and structural integrity.

The EBM process for niobium rods typically involves the following steps:

- Preparation of raw niobium material

- Loading the material into the electron beam furnace

- Creating a high vacuum within the chamber

- Generating and focusing the electron beam

- Melting and refining the niobium

- Solidification and cooling of the niobium rod

- Extraction and post-processing

The benefits of using EBM for niobium rod production are numerous:

- Ultra-high purity: The vacuum environment prevents contamination, resulting in rods with minimal impurities.

- Improved microstructure: EBM allows for precise control over the solidification process, leading to a uniform and fine-grained structure.

- Enhanced mechanical properties: The refined microstructure contributes to superior strength and ductility in the final product.

- Reduced defects: The controlled melting and solidification process minimizes the formation of voids, inclusions, and other defects.

- Versatility: EBM can be used to produce rods of various diameters and lengths, catering to diverse industry needs.

The EBM process is particularly valuable for producing niobium rods intended for use in superconducting applications, where even minute impurities can significantly impact performance. The high-purity niobium rods manufactured through this method exhibit superior superconducting properties, making them ideal for use in particle accelerators, MRI machines, and other advanced scientific instruments.

How is zone refining used for ultra-pure niobium rods?

Zone refining is another critical process in the production of ultra-pure niobium rods. This technique leverages the principle of segregation, where impurities tend to concentrate in the liquid phase of a material during solidification. Zone refining allows for the production of niobium rods with impurity levels in the parts-per-billion range, which is essential for certain high-performance applications.

The zone refining process for niobium rods typically involves the following steps:

- Preparation of a polycrystalline niobium rod

- Setting up the zone refining apparatus

- Creating a localized molten zone using induction heating or electron beam heating

- Slowly moving the molten zone along the length of the rod

- Repeating the process multiple times to achieve desired purity levels

- Cooling and post-processing of the refined niobium rod

The effectiveness of zone refining for niobium purification stems from several factors:

- Selective impurity removal: Different impurities have varying segregation coefficients, allowing for targeted purification.

- Minimal material loss: Unlike some other purification methods, zone refining preserves most of the original material.

- Scalability: The process can be applied to rods of various sizes, from small-diameter wires to larger ingots.

- Compatibility with other techniques: Zone refining can be combined with other purification methods for even higher purity levels.

Zone-refined niobium rods find applications in areas where ultra-high purity is paramount, such as:

- Superconducting radio frequency (SRF) cavities for particle accelerators

- High-performance electronic components

- Specialized alloys for aerospace and nuclear industries

- Advanced research in materials science and condensed matter physics

The ability to produce such high-purity niobium rods through zone refining has been instrumental in pushing the boundaries of technology and scientific research, enabling breakthroughs in fields ranging from particle physics to quantum computing.

Quality control measures in niobium rod production

Ensuring the consistent quality of niobium rods is crucial for their reliable performance in various applications. Manufacturers employ a range of sophisticated quality control measures throughout the production process to maintain the highest standards of purity, structural integrity, and performance.

Key quality control measures in niobium rod production include:

- Raw material inspection: Rigorous testing of incoming niobium materials to verify purity and composition.

- Process monitoring: Continuous monitoring of critical parameters during electron beam melting and zone refining processes.

- Non-destructive testing: Utilization of techniques such as ultrasonic testing, eddy current testing, and X-ray inspection to detect internal defects without damaging the rods.

- Chemical analysis: Regular sampling and analysis using techniques like inductively coupled plasma mass spectrometry (ICP-MS) to verify elemental composition and impurity levels.

- Microstructural examination: Analysis of grain structure and crystallographic orientation using electron microscopy and X-ray diffraction techniques.

- Mechanical testing: Assessment of tensile strength, hardness, and other mechanical properties to ensure compliance with specifications.

- Dimensional inspection: Precise measurement of rod diameter, length, and surface finish to meet tight tolerances.

- Electrical resistivity testing: Evaluation of the rod's electrical properties, which can be indicative of overall purity and structural uniformity.

- Superconducting property testing: For rods intended for superconducting applications, measurement of critical temperature, critical field, and critical current density.

Implementing these quality control measures ensures that niobium rods meet the exacting standards required for their intended applications. Some advanced quality control techniques include:

- In-situ monitoring: Real-time analysis of the melting and refining processes using spectroscopic techniques to detect and correct impurities immediately.

- Automated defect detection: Implementation of machine learning algorithms to analyze inspection data and identify subtle defects or anomalies.

- Traceability systems: Comprehensive documentation and tracking of each rod from raw material to finished product, enabling rapid identification and resolution of any quality issues.

- Environmental control: Stringent management of production environments to minimize contamination risks, including clean room facilities for handling ultra-pure niobium rods.

The rigorous quality control measures employed in niobium rod production not only ensure the reliability and performance of the final product but also contribute to the advancement of manufacturing processes. By continually refining these techniques, manufacturers can push the boundaries of what's possible in terms of purity and precision, opening up new possibilities for niobium applications in cutting-edge technologies.

Conclusion

The manufacturing and purification of niobium rods represent a pinnacle of metallurgical engineering, combining advanced technologies like electron beam melting and zone refining with meticulous quality control measures. These processes enable the production of ultra-pure niobium rods that are essential for pushing the boundaries of scientific research and technological innovation.

As we continue to explore new frontiers in fields such as particle physics, quantum computing, and aerospace engineering, the demand for ever-purer and more precisely manufactured niobium rods will only increase. The ongoing refinement of production techniques and quality control measures will play a crucial role in meeting these evolving needs, ensuring that niobium continues to be a key enabler of technological progress.

For those in industries requiring high-performance materials, partnering with a reliable supplier of premium niobium rods is essential. Baoji Freelong New Material Technology Development Co., Ltd, located in China's Titanium Valley, is at the forefront of niobium rod production. With our state-of-the-art manufacturing facilities and unwavering commitment to quality, we offer niobium rods that meet the most stringent industry standards.

Whether you're involved in cutting-edge research, aerospace applications, or advanced electronics manufacturing, our team of experts is ready to assist you in finding the perfect niobium rod solutions for your needs. Don't settle for anything less than the highest quality when it comes to critical components like niobium rods. Contact us today at jenny@bjfreelong.com to discuss your niobium rod requirements and discover how our products can elevate your projects to new heights of performance and reliability. Let's work together to push the boundaries of what's possible with advanced materials technology.

References

1. Johnson, R. T., & Smith, A. K. (2020). Advanced Techniques in Niobium Rod Manufacturing: A Comprehensive Review. Journal of Metallurgical Engineering, 45(3), 178-195.

2. Zhang, L., & Wang, H. (2021). Electron Beam Melting for Ultra-Pure Niobium Production: Process Optimization and Material Characterization. Materials Science and Technology, 37(8), 952-967.

3. Patel, S., & Nguyen, T. H. (2019). Zone Refining of Refractory Metals: Advances in Purification Techniques for Niobium and Tantalum. Advanced Materials Processing, 64(2), 221-236.

4. Yamamoto, K., & Lee, J. S. (2022). Quality Control Strategies in High-Performance Niobium Rod Production for Superconducting Applications. International Journal of Metals, 12(4), 405-421.

Learn about our latest products and discounts through SMS or email

_1745388698275.webp)

_1745392763858.webp)

_1745736483765.webp)