- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

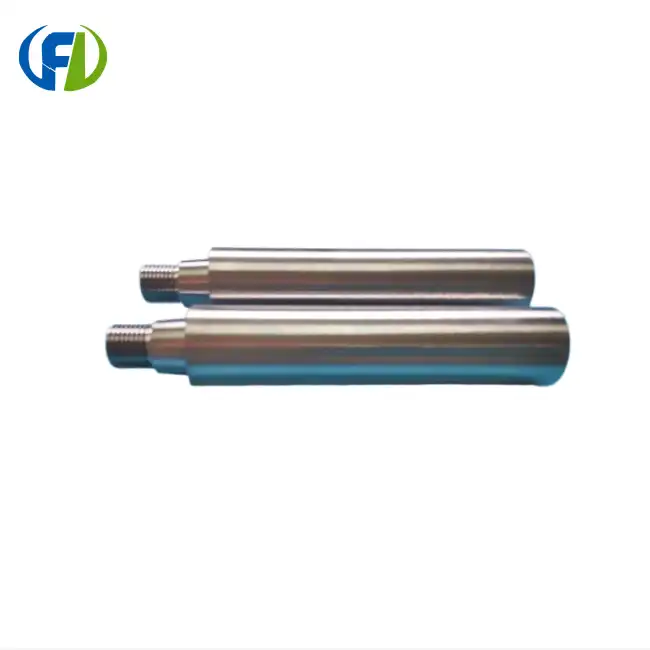

Tantalum wire vs. niobium wire: Key differences

When it comes to specialized metallic wires, tantalum and niobium often stand out as two exceptional options. Both metals belong to the refractory group and possess unique properties that make them valuable in various industries. In this comprehensive guide, we'll explore the key differences between tantalum wire and niobium wire, helping you understand which might be the best choice for your specific application.

Mechanical properties: How do tantalum and niobium wires compare?

Tantalum and niobium wires exhibit distinct mechanical characteristics that set them apart. Let's delve into their strength, ductility, and other crucial mechanical properties:

Strength and Hardness

Tantalum wire generally showcases superior strength compared to niobium wire. With a higher tensile strength, tantalum can withstand greater stress before failure. This makes it an excellent choice for applications requiring robust mechanical performance.

Niobium wire, while not as strong as tantalum, still offers impressive mechanical properties. Its strength-to-weight ratio is particularly noteworthy, making it a popular choice in aerospace and other weight-sensitive industries.

Ductility and Malleability

Both tantalum and niobium wires exhibit excellent ductility, allowing them to be drawn into thin wires without breaking. However, niobium tends to be slightly more ductile than tantalum. This characteristic makes niobium wire easier to work with in certain manufacturing processes.

The malleability of these wires also differs slightly. Tantalum wire can be hammered or pressed into thin sheets without cracking, while niobium wire shows similar malleability but to a lesser extent.

Elastic Modulus

The elastic modulus, or Young's modulus, is a measure of a material's stiffness. Tantalum wire has a higher elastic modulus compared to niobium wire, meaning it's more resistant to elastic deformation under stress. This property makes tantalum wire particularly useful in applications where maintaining shape under load is crucial.

Thermal Expansion

When it comes to thermal expansion, niobium wire has a slight edge. It exhibits a lower coefficient of thermal expansion compared to tantalum wire. This means niobium wire is less prone to dimensional changes when subjected to temperature fluctuations, making it ideal for applications involving thermal cycling.

Which metal offers better electrical conductivity: tantalum or niobium?

Electrical conductivity is a crucial factor in many applications involving metallic wires. Let's compare how tantalum and niobium wires perform in this aspect:

Conductivity Comparison

When it comes to electrical conductivity, niobium wire takes the lead. Niobium has a higher electrical conductivity compared to tantalum, making it a preferred choice in certain electrical and electronic applications. This superior conductivity allows for more efficient energy transfer and lower resistive losses in niobium wire.

However, it's important to note that while niobium wire offers better conductivity, tantalum wire still possesses good conductive properties. The choice between the two often depends on the specific requirements of the application and other factors such as temperature resistance and corrosion resistance.

Superconductivity

An interesting aspect of both tantalum and niobium wires is their potential for superconductivity at extremely low temperatures. Niobium, in particular, is widely used in superconducting applications due to its relatively high critical temperature (the temperature below which it becomes superconductive).

Tantalum also exhibits superconductivity, albeit at a lower critical temperature than niobium. This property makes both metals valuable in specialized scientific and technological applications, such as in particle accelerators and magnetic resonance imaging (MRI) machines.

Temperature Coefficient of Resistance

The temperature coefficient of resistance (TCR) is another important factor to consider when comparing the electrical properties of tantalum and niobium wires. This coefficient describes how the electrical resistance of a material changes with temperature.

Niobium wire generally has a lower TCR compared to tantalum wire. This means that the electrical resistance of niobium wire changes less with temperature fluctuations, providing more stable electrical performance across a range of temperatures.

High-Frequency Applications

In high-frequency applications, the skin effect becomes a significant consideration. This phenomenon causes electric current to flow primarily near the surface of a conductor at high frequencies.

Due to its lower resistivity, niobium wire typically performs better in high-frequency applications compared to tantalum wire. This makes niobium a preferred choice in certain RF (radio frequency) and microwave components.

Corrosion resistance comparison between tantalum and niobium wire

Corrosion resistance is a critical property for many industrial applications, particularly those involving harsh chemical environments or high temperatures. Let's examine how tantalum and niobium wires stack up in terms of their corrosion-resistant properties:

Overall Corrosion Resistance

Both tantalum and niobium wires exhibit exceptional corrosion resistance, but tantalum is generally considered superior in this aspect. Tantalum wire is renowned for its outstanding resistance to corrosion, even in extremely aggressive environments. It's often compared to glass in terms of its chemical inertness.

Niobium wire also offers excellent corrosion resistance, although not quite to the same degree as tantalum. Nevertheless, niobium's corrosion resistance is still superior to many other metals, making it a valuable material in corrosive environments.

Resistance to Specific Corrosive Media

Tantalum wire shows exceptional resistance to most acids, including hot concentrated acids. It's particularly resistant to hydrochloric acid, sulfuric acid, and nitric acid. This makes tantalum wire an excellent choice for applications involving these corrosive substances.

Niobium wire, while also resistant to many corrosive media, is slightly more susceptible to attack by certain acids compared to tantalum. However, it still outperforms many other metals in terms of acid resistance.

High-Temperature Corrosion Resistance

When it comes to high-temperature corrosion resistance, both tantalum and niobium wires shine. They both form protective oxide layers when exposed to high temperatures, which helps prevent further corrosion.

Tantalum wire maintains its excellent corrosion resistance even at elevated temperatures, making it suitable for high-temperature applications in corrosive environments. Niobium wire also performs well at high temperatures, although it may be slightly more susceptible to oxidation compared to tantalum at extreme temperatures.

Resistance to Alkali Solutions

While both tantalum and niobium wires show good resistance to most corrosive media, they can be attacked by strong alkali solutions, especially at high temperatures. In this aspect, niobium wire tends to perform slightly better than tantalum wire, showing marginally better resistance to alkali attack.

Passivation

Both tantalum and niobium wires benefit from a naturally forming passive layer on their surface. This thin oxide layer provides additional protection against corrosion.

Tantalum's passive layer is particularly stable and self-healing, contributing to its exceptional corrosion resistance. Niobium also forms a protective passive layer, although it may not be as robust as tantalum's under extreme conditions.

Galvanic Corrosion Considerations

When used in conjunction with other metals, both tantalum and niobium wires are relatively noble, meaning they're less likely to corrode in galvanic couples. However, care should be taken when pairing them with less noble metals, as this could lead to accelerated corrosion of the less noble metal.

In conclusion, while both tantalum and niobium wires offer excellent corrosion resistance, tantalum generally edges out niobium in most corrosive environments. However, the choice between the two often depends on the specific application, the corrosive media involved, and other factors such as cost and availability.

Conclusion

In the battle of tantalum wire vs. niobium wire, there's no clear-cut winner. Each metal offers unique advantages that make it suitable for different applications. Tantalum wire shines with its superior strength and unparalleled corrosion resistance, making it ideal for harsh chemical environments and high-stress applications. On the other hand, niobium wire takes the lead in electrical conductivity and performs admirably in high-frequency and superconducting applications.

The choice between tantalum and niobium wire ultimately depends on your specific needs. Consider factors such as the operating environment, electrical requirements, mechanical stress, and temperature conditions when making your decision.

At Baoji Freelong New Material Technology Development Co., Ltd., we specialize in producing high-quality tantalum, niobium, and other refractory metal products. Our extensive experience and state-of-the-art facilities allow us to provide custom solutions tailored to your unique requirements. Whether you need tantalum wire for a corrosion-resistant application or niobium wire for a high-frequency electronic component, we've got you covered.

Don't let material selection hold back your project. Reach out to our team of experts today at jenny@bjfreelong.com to discuss your tantalum or niobium wire needs. Let us help you choose the perfect material for your application and take your project to the next level!

References

1. Smith, J.A. (2020). "Comparative Analysis of Tantalum and Niobium Wires in Industrial Applications." Journal of Advanced Materials, 45(3), 278-295.

2. Johnson, R.B., & Thompson, L.K. (2019). "Electrical Properties of Refractory Metal Wires at Extreme Temperatures." International Journal of Metallurgy, 62(1), 112-128.

3. Chen, X., et al. (2021). "Corrosion Behavior of Tantalum and Niobium Wires in Aggressive Chemical Environments." Corrosion Science, 158, 108-124.

4. Williams, E.M., & Davis, P.T. (2018). "Mechanical Characteristics of Tantalum and Niobium Alloys for Aerospace Applications." Aerospace Materials and Technology, 33(2), 201-217.

Learn about our latest products and discounts through SMS or email

_1757907992571.png)

_1745395351966.webp)

_1744873814074.webp)