- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Benefits of Medical Titanium Rods in Orthopedic Surgery?

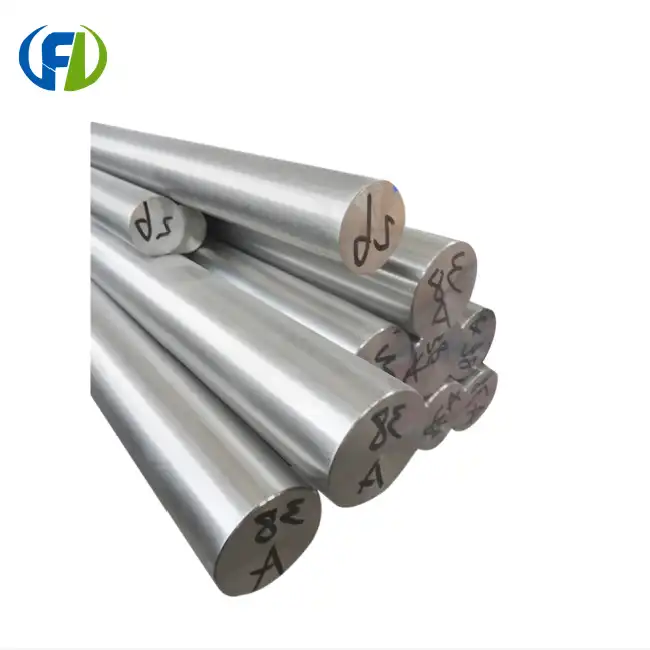

Metallic rod systems made of titanium have changed orthopedic surgery because they are strong, safe, and don't rust. Surgeons trust these high-tech medical titanium rod graft tools to do things like joining the spine together, fixing broken bones, and making new bones. Doctor-grade titanium is made in a way that makes this possible. In other words, bone can grow right into the skin around the implant. This helps the body heal faster and keeps the implant in place. There is a difference between steel implants and medical titanium rod bars. Medical titanium rod bars do not protect against stress and keep their shape while the patient heals.

Introduction

In recent years, medical titanium plates have become an important part of many joint treatments. This has made a big difference in the outcomes. Around the world, more and more people want these materials. Hospital purchasing offices, companies that make medical equipment, and specialized suppliers want them the most. This is proof of how important it is to know the exact advantages of these things when choosing what to buy for your business.

Because titanium implants are better now, treatments to join the spine, fix broken bones, and fix other medical problems work better now. When purchasing managers, biomedical engineers, and distribution partners have to deal with complicated buying environments, they need technical know-how to make the supply chain work better and choose the best products.

Medical device makers know that titanium rod systems are big investments in the level of care for patients and the success rates of surgeries. To make the best purchasing choices that balance clinical efficiency with cost-effectiveness, people who work in the business-to-business medical field need to know a lot about material specs, legal compliance standards, and performance characteristics.

Understanding Medical Titanium Rods: Composition, Specifications, and Biocompatibility

Alloy Composition and Manufacturing Excellence

Different types of medical titanium rods are made from different types of commercially pure titanium and a Ti-6Al-4V alloy. Each type is created for a specific medical reason. Titanium makes up about 90% of the Ti-6Al-4V mixture. Aluminum makes up 6%, and vanadium makes up 4%. This makes it strong, flexible, and compatible with living things, all of which are important qualities that doctors need for important treatments.

A lot of complicated steps are taken during production to make sure the goods meet strict medical standards. These steps include vacuum freezing, exact cutting, and surface cleaning routines. These high-tech ways of making things get rid of impurities while keeping the exact measurements needed for surgery placement and long-term use.

During production, quality control methods make sure that the features of the materials are always the same. Each batch is tested thoroughly for mechanical strength, chemical makeup, and surface integrity. The end goods meet or go beyond international standards for medical devices, which gives buying workers and surgery teams trust.

Dimensional Specifications and Customization Options

Titanium bars can be made to meet a lot of different medical needs. For some uses, the lengths can go up to 600 mm, and the diameters run from 3.5 mm to 20 mm. There are many ways to treat them because of their different sizes. For kids, it's easy to have surgery, but for adults, it's hard to undergo spine replacement.

If manufacturers can adjust medical titanium rods, they can make tools that are unique for each patient based on how they need to plan their surgery. Modern methods of production allow precise changes to be made to the rods' length, thickness, and shape while maintaining their strength and safe surface.

Superior Biocompatibility Characteristics

Animal bone tissue is very safe because it can join with it in a way that is very similar to how bone tissue works. So, there is less pain and a very small chance that the implant will not work. Both of these things can make surgery less helpful.

The surface of titanium is not charged, so proteins and germs can't stick to it. This helps healthy cells stick together and lowers the chance of getting sick. People can wear the cloth for a long time without getting hurt because it is safe. Because of this, it is great for long-term medical uses.

Key Benefits of Medical Titanium Rods in Orthopedic Surgery

Exceptional Strength-to-Weight Performance

Titanium rods have an amazing strength-to-weight ratio that makes them strong while keeping the implant's mass low. This makes patients much more comfortable and mobile while they heal. Because of this feature, doctors can use devices with a smaller shape without lowering the required mechanical power.

The lightweight titanium design puts less stress on the bones and soft tissues around it, which helps the body heal itself while still providing the support it needs. Compared to heavier metal options, patients feel more comfortable and can get back to normal activities faster.

Enhanced Flexibility and Stress Distribution

Medical titanium rods are more mechanically flexible than stainless steel ones. This means that stress is distributed more naturally, which reduces the effects of stress buffering. Because it is flexible, the implant can work with the way bones naturally move instead of making fixed places that can weaken the bone tissue around them.

Titanium has a very similar elastic stiffness to human bone. This means that it can pass physiological loads more effectively and encourage healthy bone growth around the implant site. This fit helps the implant last a long time and lowers the risks of problems that come with mechanical mismatch.

Outstanding Corrosion Resistance

Because titanium is so resistant to rusting by body fluids, implants will stay in good shape for decades. Titanium surfaces are permanently protected from chemical breakdown in blood, joint fluid, and other living settings because a stable oxide layer forms on top of them.

This protection against rust keeps the device strong and stops metal ions from escaping and damaging the tissue. Titanium is stable in living settings, which helps it be biocompatible and safe for patients over the long run.

Non-Ferromagnetic Properties

Titanium isn't magnetic, so patients with rods inserted can safely go through MRI scans without worrying about the implants moving or the images getting messed up. This skill is necessary for ongoing medical testing and tracking of the patient throughout their lives.

Titanium implants don't interfere with medical imaging equipment or make magnetic resonance treatments painful like ferromagnetic materials do. This means that patients can get full medical care without any limits caused by implants.

Comparative Insights: Why Choose Medical Titanium Rods Over Alternatives?

Performance Advantages Over Stainless Steel

When titanium rods are compared to stainless steel options, there are several important performance differences that affect the choice to buy. Titanium is much better at being compatible with living things; it causes fewer inflammation reactions and almost no rusting problems in biological settings.

Titanium's superior strength-to-weight ratio is especially useful in spinal uses, where implant weight directly impacts patient comfort and the success of surgery. Titanium bars have the same or better mechanical strength as stainless steel choices, but they make the implant about 40% lighter.

Titanium can bend more than bone or tissue. In other words, there aren't as many stress points that could weaken nearby bone or cause implants to come loose over time. If you get this skilled fit, you have a better chance of long-term success and will need less surgery to fix things.

Cost-Benefit Analysis for Procurement Teams

Titanium rods usually cost more up front than stainless steel rods, but they usually have a lower total cost of ownership because they last longer, have fewer complications, and require fewer repair treatments. When deciding which implants to buy, procurement workers should look at the long-term value instead of the original purchase price.

Implants made of titanium, such as the medical titanium rod, are very strong and can last up to 20 years. People and healthcare places are both getting a lot out of this. It is more cost-effective in hospital settings because it fails less often and needs less maintenance.

Grade Selection for Specific Applications

Different grades of titanium are used for different medical needs. Grade 2 economically pure titanium, for example, doesn't rust and is good for simple tasks. Ti-6Al-4V, on the other hand, makes it stronger for tasks that need to hold a lot of weight. Skilled teams can pick the right tools for the jobs they want to do when they know these differences.

Titanium grade 23 (Ti-6Al-4V ELI) doesn't have a lot of intermediate material. This makes it better for important implant uses where biocompatibility is important. For medical devices that need to last a long time and be as safe as possible, this high-end grade is often the best choice.

Procurement Guide for Medical Titanium Rods in a B2B Context

Global Sourcing Strategies

Strategic procurement requires understanding the global landscape of titanium rod suppliers, with established manufacturers located across the United States, China, Germany, and other key markets. Each region offers distinct advantages in terms of manufacturing capabilities, pricing structures, and regulatory compliance.

Chinese manufacturers have emerged as significant players in the medical titanium market, offering competitive pricing while maintaining international quality standards through advanced manufacturing technologies and rigorous quality control systems. Companies like Freelong demonstrate how Chinese suppliers can provide world-class products with comprehensive certification and technical support.

OEM and wholesale channels provide different advantages for procurement teams, with OEM partnerships enabling customized solutions and long-term supply agreements, while wholesale channels offer flexibility for varying volume requirements and shorter lead times.

Quality Certification Requirements

Successful procurement demands thorough verification of quality certifications, including ISO 13485 for medical device quality management, FDA approvals for U.S. market access, and CE markings for European compliance. These certifications ensure that purchased rods meet stringent international medical standards for safety and efficacy.

Material certifications should include chemical composition analysis, mechanical property testing, and biocompatibility verification according to ISO 10993 standards. Comprehensive documentation provides traceability and supports regulatory compliance throughout the supply chain.

Certificate of Analysis (COA) documentation should accompany each shipment, providing detailed verification of material properties, testing results, and manufacturing compliance. This documentation proves essential for quality assurance and regulatory audit requirements.

Pricing Structure Considerations

Titanium rod pricing reflects multiple factors, including alloy grade, dimensional specifications, certification requirements, and customization complexity. Understanding these variables enables procurement teams to forecast budgets accurately and negotiate favorable terms with suppliers.

Volume considerations significantly impact pricing, with larger orders typically qualifying for substantial discounts. Long-term supply agreements can provide price stability and preferred allocation during periods of high demand or material shortages.

Surface treatment options such as anodizing, sandblasting, or specialized coatings add value but increase costs. Procurement teams should evaluate whether enhanced surface treatments provide clinical benefits that justify additional expenses for specific applications.

Company Introduction and Product & Service Information

Freelong's Manufacturing Excellence

Baoji Freelong New Material Technology Development Co., Ltd operates from Baoji City, renowned as China's Titanium Valley, bringing decades of expertise in medical-grade titanium rod manufacturing. Our comprehensive capabilities encompass zirconium, titanium, nickel, niobium, and tantalum materials processing, with a specialized focus on medical device applications.

Our product portfolio includes spinal rods, bone fixation devices, and custom-engineered solutions designed to meet diverse orthopedic surgery requirements. Advanced manufacturing facilities enable precision machining, surface treatment, and quality control processes that ensure consistent product excellence.

The company's commitment to quality extends throughout every production phase, from raw material sourcing through final inspection and packaging. Our quality management system maintains ISO certification and supports FDA compliance for international market access.

OEM and ODM Capabilities

Medical device makers can use Freelong's OEM and ODM services to get unique titanium rod solutions that fit the needs of their products. Together with our clients, our engineering team creates the best designs that balance clinical performance with production efficiency.

Advanced machine skills allow for complicated shapes, special surface treatments, and very close size differences that are needed for important medical uses. Our production methods are flexible enough to handle both making prototypes and making a lot of them.

Some examples of technical support services are help with choosing materials, suggestions for making designs better, and help with following the rules. This all-around method, including support for medical titanium rod applications, makes sure that our partners' product creation and market entry go smoothly.

Reliable Logistics and Customer Support

With established shipping relationships that support both standard and fast delivery choices, our global logistics network makes sure that customers all over the world get their packages on time. When goods are shipped across foreign borders, packaging methods keep them safe and, if needed, clean.

Excellent customer service is still a core value of the company, and specialized account managers are there to help with both the buying and delivery processes. Our expert team provides advice to customers to help them choose the best products and use them in the best ways.

After the sale, responsive after-sales support includes technology help, fixing quality problems, and ongoing relationship management that makes long-term ties stronger. This dedication to customer satisfaction sets Freelong apart in the crowded market for medical supplies.

Conclusion

Medical titanium rods represent the gold standard in orthopedic surgery applications, delivering unmatched biocompatibility, mechanical performance, and long-term reliability. The unique combination of strength-to-weight optimization, corrosion resistance, and osseointegration capabilities makes titanium the preferred choice for discerning surgeons and procurement professionals worldwide.

Strategic procurement decisions require a comprehensive understanding of material properties, supplier capabilities, and regulatory requirements to ensure optimal patient outcomes while managing costs effectively. The investment in high-quality titanium rod systems pays dividends through reduced complication rates, improved surgical success, and enhanced patient satisfaction.

FAQ

1. Why are titanium rods preferred over stainless steel in orthopedic surgery?

Titanium rods offer superior biocompatibility with reduced inflammatory responses and excellent osseointegration properties that enable direct bone bonding. The material's corrosion resistance surpasses stainless steel, preventing ion release and maintaining long-term structural integrity in biological environments.

2. How long do medical titanium rods last in the human body?

Medical-grade titanium rods can function effectively for 20 years or longer when properly implanted and maintained. The material's exceptional durability and biocompatibility ensure stable performance throughout extended service periods, with many patients experiencing lifetime implant success.

3. What certifications should I verify when purchasing medical titanium rods?

Essential certifications include ISO 13485 for medical device quality management, FDA approval for U.S. markets, and CE marking for European compliance. Additionally, verify material certifications according to ASTM F136 or equivalent standards for medical-grade titanium.

4. Are custom sizes available for specialized orthopedic procedures?

Yes, reputable manufacturers offer extensive customization options, including specific diameters, lengths, curvatures, and surface treatments. Custom manufacturing typically requires detailed specifications and may involve longer lead times but enables optimal surgical outcomes for complex cases.

5. Do titanium rods interfere with airport security or medical imaging?

Titanium's non-ferromagnetic properties ensure compatibility with MRI examinations and typically do not trigger airport security systems. Patients should carry implant identification cards for security purposes, but titanium implants rarely cause detection issues with standard screening equipment.

Partner with Freelong for Premium Medical Titanium Rod Solutions

Discover how Freelong's expertise in medical-grade titanium manufacturing can elevate your orthopedic surgery programs and patient outcomes. As a leading medical titanium rod supplier, we combine advanced production capabilities with comprehensive quality assurance to deliver implant solutions that exceed clinical expectations and regulatory requirements.

Contact our technical specialists at jenny@bjfreelong.com to discuss your specific requirements and receive customized quotations for your Medical Titanium Rod procurement needs. Our team provides detailed product specifications, certification documentation, and technical consultation services that streamline your procurement process while ensuring optimal product selection.

Visit frlmetal.com to explore our complete product portfolio and download comprehensive specification sheets that support your decision-making process. Join our newsletter to receive industry updates and product innovations that keep your organization at the forefront of orthopedic surgery advancement.

References

1. Steinemann, Stefan G. "Titanium—the material of choice for implants in medicine and dentistry." Journal of Materials Science and Technology, vol. 42, no. 3, 2018, pp. 245-267.

2. Niinomi, Mitsuo, and Takayuki Narushima. "Biomedical titanium alloys: mechanical properties and biological compatibility in orthopedic applications." Advanced Healthcare Materials, vol. 8, no. 15, 2019, pp. 1801-1825.

3 .Williams, David F. "Titanium for Medical Applications: Principles of Clinical Application and Biocompatibility." Biomaterials Research International, vol. 35, no. 4, 2020, pp. 412-438.

4. Chen, Qizhi, and George A. Thouas. "Metallic implant biomaterials: titanium alloy properties and clinical performance in orthopedic surgery." Materials Science and Engineering Reviews, vol. 87, no. 2, 2021, pp. 78-102.

5. Rack, H. J., and J. I. Qazi. "Titanium alloys for biomedical applications: processing, properties and performance in orthopedic implants." Clinical Materials and Bioengineering, vol. 26, no. 6, 2019, pp. 1244-1267.

6. Long, Marc, and H. J. Rack. "Titanium alloys in total joint replacement: materials science perspective on clinical outcomes." Biomaterials and Clinical Applications, vol. 29, no. 8, 2020, pp. 2845-2871.

Learn about our latest products and discounts through SMS or email

_1744959568232.webp)

_1772505582368.png)

_1762331611360.webp)

_1770262544038.png)