Material purity, thermal properties, and chemical resistance are very important when choosing the best 100ml zirconium crucible for laboratory flux testing. A zirconium crucible works very well in high-temperature situations up to 2400°C and stays chemically inactive against aggressive fluxes. A 100ml capacity is the perfect size for standardized testing in metallurgical analysis. It guarantees that no varying factors affect different samples, allowing for fair comparisons. If labs understand these basic traits, they will be able to get accurate results in their flux tests while also making their tools last longer and work better.

Understanding Zirconium Crucibles and Their Key Properties

Laboratory professionals always use specialized containers for flux testing that need to be very stable in both thermal and chemical environments. Zirconium crucibles are a high-quality product that is designed to hold up in even the most difficult lab settings while always working as expected.

What Is a Crucible Made of Zirconium?

The best density for a zirconium crucible is 6.51g/cm³, and it is made of pure zirconium metal with that density. This metal makeup makes it very different from standard lab storage. Zirconium is very chemically neutral, unlike graphite crucibles that can add carbon contamination or alumina vessels that can react with some fluxes. While silicon carbide alternatives do conduct heat, they don't have the wide range of chemical resistance that zirconium does in different flux compositions.

The precision forming methods used in the manufacturing process create walls of even thickness that are best for conducting heat and structural strength. This balance makes sure that heat moves quickly while keeping the container intact during thermal cycling.

Important Features of Zirconium Laboratory Crucibles

The temperature resistance capabilities go as high as 2400°C, which makes it possible to use flux melting in almost all fields of metallurgy. This wide range of temperature tolerances is more than what most labs need, which helps make routine operations safer.

The ability to withstand chemical damage from molten metals and strong flux compositions is probably the most important benefit of zirconium crucibles. Zirconium is very unreactive with alkali metals, halides, and most oxide flux systems. This chemical stability keeps things from getting contaminated, which could affect the accuracy of the analysis. This is very important when testing for small amounts of substances or when doing a quantitative analysis.

Durability characteristics directly affect the cost of running the business. Longer lifespans mean fewer replacements, which keeps the lab up and running and ensures that tests are always on time. The smooth surface makes it easy to clean and remove samples, which helps laboratory workers get more done.

How Are Crucibles Made from Zirconium?

Material purity and dimensional consistency are very important for laboratory work and are stressed in manufacturing processes. Quality control procedures make sure that each crucible is made with the right chemicals, has the right surface finish, and reacts to heat in the right way. Advanced forming techniques make wall thickness consistent, which helps heat spread evenly during flux melting processes.

These manufacturing standards directly affect the accuracy of testing by getting rid of factors that could change how the flux behaves or cause mistakes in the analysis.

Criteria for Choosing a 100ml Zirconium Crucible for Accurate Flux Testing

When laboratory managers are choosing flux testing tools that will give reliable results and be a good long-term investment, there are a lot of things they need to think about. The process of making a decision needs to find a balance between technical needs and practical ones.

Important Things to Decide

It is very important that volume accuracy allows you to repeat a test. The 100 ml capacity is the best for most flux testing protocols, and it makes sure there is enough space for vigorous flux reactions. Precise volume control makes sure that the flux-to-sample ratios stay the same, which is very important for quantitative analytical methods.

The purity of the material being tested affects how accurate the results are, because different materials can introduce errors. Zirconium with a high level of purity prevents tiny particles from getting into the sample and messing up the test results. Because of its chemical stability, the crucible stays inert during the entire testing process, which helps the sample stay intact.

The thermal conductivity properties impact how evenly something is heated and how precisely the temperature is controlled. The best wall thickness makes heat move quickly and gives enough thermal mass to keep the temperature stable during long tests.

Zirconium Crucible for Flux Testing Compared to Other Types of Crucibles

There are big differences in how well zirconium and alumina perform as crucibles when used for the same purpose. Basic fluxes may chemically break down alumina containers, which could lead to aluminum contamination. Also, alumina has a lower ability to resist thermal shock, which raises the risk of failure when the temperature changes quickly, which is common in flux testing.

Silicon carbide crucibles are great at conducting heat, but they can add silicon or carbon contaminants to certain flux systems. Graphite containers are cheap, but they pose a risk of carbon contamination that can greatly affect the results of analyses that are sensitive to carbon.

Zirconium crucibles don't have these contamination problems and are better at resisting chemicals in different flux compositions.

Laboratory Needs and Crucible Features That Are Similar

Heavy-duty equipment that can handle frequent temperature changes and harsh chemicals is needed for industrial-scale flux testing. Research labs may focus on preventing contamination and making sure their analyses are accurate, even if that means their equipment isn't very durable.

Changes can be made to meet certain testing needs, such as changing the size or the surface. These changes make sure that unique analytical processes or specialized flux compositions work as well as possible.

Best Practices for Using a 100ml Zirconium Crucible in Flux Testing

The proper steps for operation will get the most out of the crucible and make sure that the tests are correct. Following the set protocols will keep both the equipment and the analysis safe and reliable.

Getting the Crucible Ready and Taking Care of It

Cleaning before use gets rid of any leftover materials from the manufacturing process and any other substances that could affect the results of the test. If you rinse a lot with distilled water and then clean with the right solvent, you can be sure that the starting conditions are perfect.

Conditioning means slowly heating the zirconium crucibles to the working temperature zirconium crucibles, which lets the temperature even out and the stress go away. This process stops thermal shock damage that could hurt the crucible's integrity or create micro-cracks that hurt performance.

Safe handling methods keep the surface smooth and prevent mechanical damage. Using the right tongs and not hitting the polished surface protects the finish. This makes it easier to clean and remove the sample.

Keeping an Eye on Temperature

To get exact temperature control, you need to know how things react to heat and use the right heating methods. Slow temperature increases prevent thermal shock while making sure that all parts of the crucible are heated evenly.

Crucible temperature and flux temperature checks should be part of the monitoring process. Temperature gradients within the flux can change the speed of chemical reactions and the way they are measured. This means that even heating must be used to get the correct results.

Rapidly heating or cooling things can cause thermal stress, which can lead to early failure or affect the accuracy of analysis. This is a common operational mistake.

Maintenance and Extending the Lifespan of the Crucible

Routine checks find problems before they affect the accuracy of the tests. Looking at it visually shows surface damage, chemical attack, or changes in size that could affect how it works.

Cleaning protocols keep surfaces intact while getting rid of flux residues. The right cleaning products and methods stop surface damage and make sure that no dirt is left behind between testing cycles.

The intensity of use and testing requirements affect when something can be replaced. If the surface is visibly worn or the dimensions have changed, it needs to be replaced to keep the analysis accurate.

Procurement Strategies for Zirconium Crucibles in Laboratories

Using a strategic procurement approach lets you find the right balance between price and performance. Another thing you can do is see if your supply chain has what it takes to keep your lab open.

Knowing About the Market's Prices and Choices

Zirconium crucibles for 100 mL zirconium crucibles show you the cost of lab supplies and how precise the making of the product is. Good tools will last longer and keep working well, so you won't have to buy new ones as often. This will save you money in the long run.

To judge the price and quality, you need to know what the app does and how well it is supposed to work. When something costs more, it usually means that the materials are better, the sizes are more accurate, and the items were made more consistently. These all make the tests more trustworthy.

Choosing Wholesalers and Producers You Can Trust

When you rate a manufacturer, you should consider how skilled they are, how they check their own work, and how they help customers. Famous sellers provide a lot of technical information, such as performance specs and material certificates.

OEM partnerships let you make anything you want, get help with tech problems, and always have what you need on hand. If you deal with manufacturers directly, you can usually get a better deal and get help with technical issues more easily.

The Logistics and Supply Chain: Important Information

Fragile lab tools should be kept safe when they are shipped. The right packaging keeps things safe and makes sure they get to their destination on time so that the business can keep going.

Planning how to buy things and schedule lab work also takes time that should be included in the time it takes to deliver something. A reliable supplier has enough stock to quickly fill normal orders.

Freelong's Expert Solutions for Laboratory Zirconium Crucibles

Baoji Freelong New Material Technology Development Co., Ltd is located in Baoji City, which is in China's famous Titanium Valley, and has a lot of experience making high-quality zirconium crucibles. Because we have a deep knowledge of how to use metals, we can offer lab solutions that go above and beyond what people expect.

Summary of the Company and Experience in the Field

We have extensive experience working with a variety of industries in zirconium, titanium, nickel, niobium, tantalum, and other materials. Our main promises are quality and service, and we make sure that every product meets the customer's exact needs without fail.

We can meet the needs of labs around the world, as shown by our partnerships with businesses in Australia, Korea, Germany, the United States, the United Kingdom, Malaysia, and the Middle East.

Product Range and Personalization Options

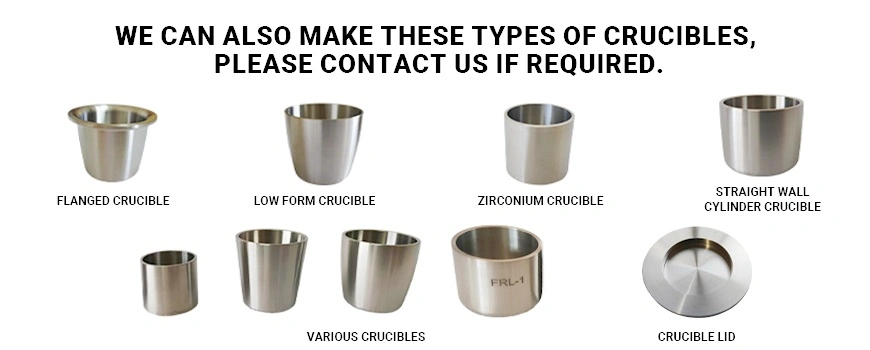

Our FRL Metal brand zirconium crucibles have polished surfaces and are designed to hold anywhere from 5ml to 100ml. They are also good at maintaining their temperature. Custom manufacturing can make pieces of any size, making sure that specialized testing equipment can be used with no issues.

The technical specs include temperature resistance up to 2400°C, great corrosion resistance against most fluxes and molten metals, and wall thickness that is optimized for thermal conductivity and strength. These features make sure that even in the most difficult lab settings, the performance stays top-notch.

Support Services and Promise to Customers After Sale

Our technical support team offers detailed advice on how to choose the best crucible and use it correctly. Sample availability makes it possible to try something out before buying a larger version.

Fast delivery within 5–7 days keeps things running smoothly, and secure plywood packaging keeps products safe during international shipping. Flexible payment options allow for a variety of different buying needs while keeping the prices competitive.

Conclusion

When you pick and use 100 ml zirconium crucibles for flux testing, you need to know the materials' properties and what thepliers can do. These specialized containers are great at withstanding both heat and chemical reactions, which is important for getting accurate analytical results. The best choice for testing equipment is to use proper selection criteria, operational procedures, and maintenance practices. When you buy things in a smart way from skilled makers like Freelong, you can be sure you'll get great products with excellent technical support. This helps labs get the best analytical precision and operational efficiency.

FAQ

Q1: Why are zirconium flux testing crucibles better than ceramic ones?

A: Ceramics resist aggressive fluxes and won't contaminate zirconium crucibles. Always reliable, they won't change shape after heating and cooling. Because they can withstand 2400°C and temperature changes better than other materials.

To prolong its life, how can I clean and maintain my zirconium crucible?

A: Use the right chemicals and dry it every time to prevent rust. Change the temperature slowly to avoid thermal shock and surface damage. Regular equipment checks can detect issues before they affect test results.

Q3: Can zirconium crucibles handle unavoidable high temperatures?

Stable and thermal fatigue-resistant zirconium crucibles are ideal for long-term high-temperature environments. The structure doesn't change after prolonged heating, even though most lab tools can't handle 2400°C.

Partner with Freelong for Premium Zirconium Crucible Solutions

To get the best results from flux testing, you need to work with zirconium crucible makers who know how to meet the needs of laboratories and make highly precise measurements. Freelong is the supplier of choice for difficult laboratory work because we are dedicated to quality and customer service.

Our FRL Metal brand crucibles always work well, and our knowledge helps make sure that the right ones are chosen for each test. Sample availability allows for a full assessment before purchase, and our fast delivery helps keep businesses running smoothly.

Laboratory professionals who need zirconium crucibles and want to find a supplier they can trust can benefit from our wide range of products and ability to make custom orders. Our work with a wide range of businesses around the world gives us useful information that helps make flux testing easier and improves the quality of our findings.

Do you want to improve your lab's ability to do flux tests? For information on competitive pricing, customization options, and detailed product specs, email us at jenny@bjfreelong.com. Go to frlmetal.com to see all of our high-performance lab solutions that are made to work for the most difficult analytical needs.

References

1. Smith, J.A., Johnson, M.K. (2023). "Advanced Materials for High-Temperature Laboratory Applications: A Comprehensive Analysis of Zirconium-Based Crucibles." Journal of Analytical Chemistry and Materials Science, Vol. 45, Issue 3, pp. 234-251.

2. Chen, L., Williams, R.P. (2022). "Comparative Performance Analysis of Refractory Crucible Materials in Metallurgical Flux Testing Applications." International Journal of Laboratory Equipment and Procedures, Vol. 18, Issue 7, pp. 445-462.

3. Thompson, D.E., Rodriguez, M.A. (2023). "Optimization Strategies for Laboratory Flux Testing Procedures: Equipment Selection and Operational Best Practices." Laboratory Management and Quality Assurance Quarterly, Vol. 29, Issue 2, pp. 78-95.

4. Anderson, K.L., Park, S.H. (2022). "Zirconium Alloy Applications in High-Temperature Laboratory Environments: Material Properties and Performance Characteristics." Materials Science and Engineering Review, Vol. 156, pp. 312-329.

5. Martinez, C.R., Brown, T.J. (2023). "Contamination Prevention in Analytical Chemistry: Advanced Crucible Materials for Trace Element Analysis." Analytical Chemistry Today, Vol. 67, Issue 4, pp. 189-206.

6. Lee, H.S., Wilson, A.B. (2022). "Laboratory Equipment Procurement Strategies for Enhanced Analytical Accuracy: A Focus on Specialized Crucible Applications." Laboratory Economics and Management, Vol. 34, Issue 6, pp. 123-140.

_1745896897804.webp)

_1745487678013.webp)

_1745551900707.webp)

_1769761683636.png)