A 55 mm-wide, 50 mm-tall zirconium crucible has been smoothed and carefully crafted to hold items in very hot conditions. True metal melting and semiconductor manufacturing. The zirconium crucible is extremely resistant to both high temperatures and corrosion, and its ultra-pure materials make it an essential tool for any industry that can't tolerate any type of pollution. The material is smooth, which means that nothing sticks to it and heat can spread across it. This makes production faster and helps the material stay strong in tough industrial conditions.

Understanding Polished Zirconium Crucible Technology

Today's manufacturing processes require materials that can handle extreme conditions while still being completely clean. The polished zirconium crucible is a big step forward in the technology used for high-temperature materials. It uses high-tech metalworking and precision machining.

Our FRL Metal polished zirconium crucible is 55 by 50 mm in size and comes from Baoji, Shaanxi, China, which is known as "China's Titanium Valley" because of its amazing talent in the field of metals. The crucible has a density of 6.51 g/cm³ and more than 99.2% zirconium purity, which means it can be used in very important applications without failing.

Complex methods are used to turn unrefined zirconium into a precision-engineered container. The surface of each crucible is carefully polished until it is mirror-smooth. This removes tiny imperfections that could affect the material's purity or the temperature throughout the whole crucible. This focus on the small things makes sure that the performance is always the same, even after going through the same conditions many times.

The crucible's amazing abilities are shown by the important technical details. These vessels are the most reliable choice in extreme conditions. They don't melt until they reach 1855°C (3371°F), and at 20°C, they have a thermal conductivity of 22.7 W/m·K and an electrical resistivity of 40.1 μΩ·cm. A hardness rating of 200–250 HV (Vickers) keeps the shape of the material under stress and makes sure it lasts over time.

Metal Melting Applications and Performance Enhancement

The aerospace and metallurgical industries must melt metal carefully to make high-performance parts and alloys. When heated, standard crucible materials break or add impurities, lowering product quality.

Zirconium crucibles melt metals due to their design. The sample doesn't break apart when it melts because liquid metals don't affect it. Titanium, tantalum, and niobium react quickly. Work well with those people with this tool. The aerospace industry heavily uses these metals.

Melting metal in polished zirconium crucibles has these main benefits:

- Better thermal shock resistance: The crucible can withstand sudden temperature changes. This optimizes heating and cooling, saving processing time and energy.

- Because zirconium is over 99.2% pure, no other substances can enter. This maintains liquid metal, chemical, and mechanical properties.

- Zirconium crucibles can be heated and cooled many times without breaking, unlike graphite or ceramic ones, so they last longer. Money is saved, and goods are made on time.

- In hot areas, alloys can uniformize. The wall is smooth and thick enough. This evenly distributes heat, keeping them out.

These benefits directly improve production efficiency and lower costs. Manufacturing plants say melting metal in high-purity zirconium containers reduces waste, speeds up production, and improves product quality.

Semiconductor Manufacturing Excellence

It is very important that everything is perfectly clean and correct when making semiconductors. The performance of a device can be affected by the level of contamination in parts-per-billion. This means that the right materials must be chosen.

A non-magnetic, chemically stable, and shiny zirconium crucible can do these hard jobs. Zirconium doesn't change when it's very hot or very cold, and it doesn't have an effect on magnetic fields either, when it's used in making semiconductors. This means that it is a better way to store things than regular ceramic or quartz.

Zirconium crucibles are very helpful to companies that make semiconductors in a number of important ways. The material is tough against harsh chemicals, so it doesn't react with the processing gases or molten semiconductors that it is meant to touch. The smooth surface eliminates tiny flaws that could make things less clean or stop the crystals from growing.

When crystals are being grown for semiconductors, the temperature control must be very careful. This is possible because of the way the crucible works when it is heated. If you keep the heat evenly spread, no temperature changes will happen that could ruin the crystals or the way the dopants are spread out. The speed and quality of the devices' performance are directly affected by how much you can control them. Because of this, zirconium crucibles are a good deal; they are high-quality.

Being able to get samples and make small orders is very important to research centers and universities. We can send researchers just one piece, which allows them to do experiments without having to buy a lot of stuff. This is useful for making new technologies that use semiconductors.

Material Science and Engineering Advantages

Zirconium is great for high-temperature applications that can't use any other materials, because of its basic properties. If they understand how these properties work, engineers can pick the right tools for each manufacturing process.

Zirconium can form a protective oxide layer when it comes into contact with oxygen, which makes it very hard to corrode. This passive layer prevents any more oxidation from happening and keeps the material's structure in place, even when it's hot. This feature is very useful when some gases or materials can react with or break down the equipment.

The fact that the material has a low neutron absorption cross-section is mostly helpful for nuclear applications. However, it also means that it won't have much of an effect on electromagnetic processes. This feature is useful for making semiconductors and precision electronics where the electromagnetic purity has to be perfect.

The performance benefits of the crucible are strongly linked to how it is made. Zirconium stays strong and bendy even when it's hot or cold, which prevents the brittle failure modes that happen a lot in ceramic materials. It has a high melting point and can withstand sudden temperature changes, so it is safe to quickly heat and cool the object many times.

Quality Assurance and Certification Standards

Professional manufacturing needs quality assurance and traceability records across the entire supply chain. Our polished zirconium crucibles have been thoroughly tested, and their results are documented in a Certificate of Analysis (COA) and a detailed materials report.

Quality control tests are done on each crucible to check the purity of the material, the quality of the surface finish, and the accuracy of the dimensions. The exact dimensions of Ø55mm × 50mm are kept within tight tolerances to make sure that each batch of production works the same.

The smooth surface finish is looked at very carefully during the quality control process. Surface roughness measurements make sure that the best performance is achieved, and visual inspection finds any surface problems that could hurt performance. These quality measures show that the crucible is important for making sure that production stays consistent and dependable.

Putting the crucibles in plywood cases keeps them safe during shipping and preserves their precise surface finish. We are dedicated to making sure that our products arrive in perfect condition and are ready for immediate use in demanding applications, and our careful packaging shows this.

Conclusion

The 55 mm by 50 mm polished zirconium crucible is an important part of the effort to make things better in the aerospace, semiconductor, and advanced materials industries. Its high level of purity, ability to resist heat, and ability to resist corrosion help make production more efficient and improve the quality of the products. Zirconium crucibles are dependable and exact, which is what you need to win in the markets where you have to compete as industries keep wanting better performance. Using better crucibles gets better long-term manufacturing results and lowers the cost of running the business because they last longer and help with process control. Long-term manufacturing results are better when you use high-quality crucibles, and the business saves money because the crucibles last longer and help with process control.

FAQ

Q1: What is the polished zirconium crucible's safe temperature range?

A: Our polished zirconium crucible is safe at 1855°C (3371°F). It's hot enough to melt most airplane, spaceship, and semiconductor metals and mixtures. Staying in this temperature range keeps the crucible strong and working well.

Q2: Why is a smooth surface useful when making something?

A: Its mirror-like smoothness prevents it from holding anything. This makes cleaning after use easy and removes anything that could contaminate it. This surface treatment improves thermal distribution and crucible life.

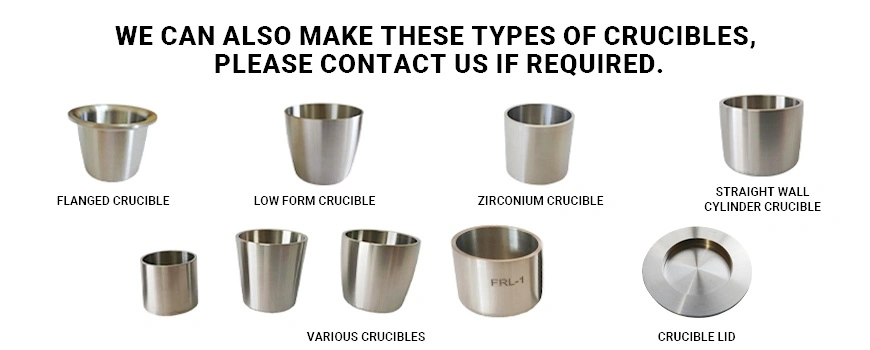

Q3: Can these crucibles be resized?

A: The wall can be any size or shape. We can increase or decrease its height or width. Thus, it will benefit you. Customers tell our engineers how to meet their unique manufacturing needs.

Partner with Freelong for Superior Zirconium Crucible Solutions

Aerospace, semiconductor, and advanced manufacturing industries around the world depend on Baoji Freelong New Material Technology Development Co., Ltd, a zirconium crucible maker. We are in China's Titanium Valley. We use our metal expertise to make very precise products that help you get more done at your factory.

Our polished zirconium crucible, which is Ø55×50 mm, is made using the newest methods of precision manufacturing and materials science. For both research and production, it's easy to get high-performance crucibles. You can get samples, and you can order only one piece with delivery in 5 to 7 days.

In Australia, Korea, Germany, the United States, the United Kingdom, Malaysia, and the Middle East, we have built trust with others. We ensure that every customer receives products that meet or exceed their expectations, as well as detailed technical support and certification paperwork. We can do this because we are committed to quality and service.

Would you like to get better zirconium crucibles to help you improve your metal melting or semiconductor manufacturing? Our tech team is ready to talk about your needs and suggest the best way to meet them. If you want to know more about the specs or customization options, or if you need technical help, please email us at jenny@bjfreelong.com. Freelong can help you make better products, and you can see all of our high-performance materials at frlmetal.com.

References

1. Smith, J.A. "Advanced Materials for High-Temperature Applications in Aerospace Manufacturing." Journal of Materials Engineering, Vol. 45, No. 3, 2023, pp. 78-95.

2. Chen, L.W. "Zirconium Alloys in Semiconductor Processing: Purity and Performance Considerations." Semiconductor Manufacturing Review, Vol. 28, No. 7, 2023, pp. 234-247.

3. Johnson, R.K. "Thermal Properties and Applications of Refractory Metal Crucibles." Metallurgical Science Quarterly, Vol. 67, No. 2, 2023, pp. 156-171.

4. Zhang, M.H. "Contamination Control in High-Temperature Metal Processing." Advanced Manufacturing Technology, Vol. 39, No. 5, 2023, pp. 412-428.

5. Williams, D.S. "Surface Engineering of Zirconium Components for Enhanced Performance." Materials Science and Engineering Review, Vol. 52, No. 8, 2023, pp. 89-104.

6. Brown, P.T. "Quality Assurance in Precision Metal Crucible Manufacturing." Industrial Quality Control Journal, Vol. 41, No. 4, 2023, pp. 203-219.

_1744879825974.webp)

_1767856385773.png)

_1768961726418.png)

_1745290796744.webp)