When it comes to semiconductors, a high-purity zirconium crucible is a special lab vessel made from zirconium metal that has been refined and is designed to work at very high temperatures. When temperatures and chemicals need to stay stable, these crucibles are a good choice. They won't lose their shape no matter how hot it is. Because they don't rust in acids, alkalis, or molten salts, they can be used to make wafers, grow crystals, and clean things. What they can do, how to choose them, and how to keep them in good shape can all help manufacturers make better chips and keep the places where they work from getting dirty.

Zirconium crucibles that are very pure: what you need to know?

There are various kinds of crucibles, but high-purity zirconium crucibles are made with more care and a better mix of materials. This stuff is mostly made of zirconium that is at least 99.2% pure. Zinc that is 99.999% pure is used to make the best ones. Picking the correct zirconium ore is the first step in making something. For a number of steps, advanced metallurgical methods are used to clean it and get rid of any dirt or other things that could change how well it works.

These are great for tough jobs because they are made to last. The fact that they are not as heavy as some other high-temperature materials (6.51g/cm³) helps them keep their shape. They are less likely to get thermal shock if you heat and cool them quickly. This is because they have a low thermal expansion coefficient. When working with semiconductors, it's important to keep an eye on the temperature because it changes the quality of the end product.

It is checked for quality during production to make sure that the performance doesn't change. There are many checks on each crucible to make sure it is the right size, has a good finish, and is made of the right things. There are a lot of rules about how to make semiconductors, and even small changes can slow down the process. This close attention to detail makes sure that every unit follows the rules.

Why is it smart to make semiconductors with very pure zirconium crucibles?

When it comes to purity, the semiconductor business needs materials that can handle rough processing and still meet very high standards. Most of the time, very pure zirconium crucibles work best. In the real world, this makes things work better and cost less to make.

They stay chemically stable in amazing ways, even when they are put in the harsh conditions that are often used to work with semiconductors. Most acids, bases, and molten salts don't react with chemicals, so they can't change things that shouldn't be changed. It is very helpful that these chemicals don't react with each other when working with cheap semiconductor materials. Even a small amount of contamination can kill whole groups of products.

It also works well in a lot of different temperatures, which is another great thing about it. You can use these crucibles to clean things and grow crystals at high temperatures because they are used to those temperatures all the time. They will always be able to take care of long production runs as long as they can keep their structure strong. This cuts down on the time lost when things break.

Crucibles made of zirconium last longer and keep out contaminants better than crucibles made of alumina or graphite. As some substances react with crucibles made of alumina, other substances can react with crucibles made of graphite. Zirconium crucibles, on the other hand, keep materials pure by providing neutral processing environments. The company makes more money because it gets more goods and doesn't waste as much.

Important Uses and Applications in the Semiconductor Business

Zirconium crucibles are very important for precise material processing techniques that are used to make semiconductors. Their main use is to melt and cast very pure silicon and germanium, which are important materials for making semiconductor devices. The ability of the crucibles to keep the material pure during these steps makes sure that the finished semiconductors meet strict performance standards.

Another important use case is crystal growth applications. Keeping environments free of contamination is very important during silicon crystal pulling processes for making high-quality wafers. Zirconium crucibles give crystals the chemical neutrality and temperature stability they need to form consistently, which has a direct effect on the electrical properties of finished semiconductor devices.

Experimental work with new semiconductor materials and alloy development is done in these crucibles in research and development labs. Because they come in small sizes (5ml to 5L), they can be used for a wide range of research projects while still meeting the high standards for purity needed in production settings. With custom sizing options, researchers can find the best crucible specifications for their experiments.

Zirconium crucibles are used in automated processing equipment on industrial production lines. The equipment's consistent performance and long service life mean that it needs less maintenance. Because they are compatible with electromagnetic heating systems and have a high electrical resistivity, the crucibles can be used for the advanced processing methods used in modern semiconductor fabrication facilities.

Zirconium crucible maintenance tips and the best ways to use them

Following the right maintenance procedures will greatly increase the service life of crucibles and ensure that they work properly throughout their entire operational period. Temperature control is the most important part of crucible care. To avoid damage from thermal shock, heating and cooling rates must be carefully managed.

By using gradual temperature ramping methods, you can keep crucibles from getting stress fractures that can happen during quick temperature changes. Heating rates of 5 to 10°C per minute are usually suggested until the operating temperature is reached. After the process is finished, controlled cooling rates of the same range should be used. This method reduces thermal stress while keeping the structure's integrity.

To keep things from getting contaminated, they need to be handled and stored carefully. Crucibles should be kept in dry, clean places that are away from things that could be a source of contamination. Before each use, the right solvents are used to clean thoroughly and get rid of any leftover materials from the last use. Any surface irregularities or signs of chemical attack that could hurt performance should be found by looking at them.

Setting up regular maintenance schedules helps find problems before they affect production. Predictive maintenance planning is possible by keeping track of operating temperatures, usage cycles, and the types of materials that are processed. If you replace the crucibles before they break, you can avoid contamination events that could affect many production batches.

How to Pick Out and Get the Correct High-Purity Zirconium Crucible?

To choose the right zirconium crucibles, you need to carefully look at the supplier's capabilities and the needs of the application. Specifications for material purity must match the needs of semiconductor processing. Higher purity grades are usually needed for advanced applications where zero tolerance for contamination is close at hand.

Dimensional factors include the amount of space needed, the wall thickness, and how well it works with other processing equipment that is already in use. Standard sizes range from 5ml units for laboratories to 5L units for factories. Custom sizes can also be made for specific uses. The thickness of the wall is usually between 1 and 5 mm, but it depends on the operating temperature and the amount of mechanical stress that needs to be handled.

The choice of surface finish affects both performance and cost. For simpler tasks, as-cast surfaces are a cheap option, but for more important tasks, machined or electropolished finishes provide a better surface quality. The polished surface finish makes sure that the part works perfectly in semiconductor applications where surface contamination needs to be kept to a minimum.

When evaluating a supplier, the main things that are looked at are their quality control skills, certification standards, and technical support services. Suppliers with a good reputation provide full material certification documents, keep quality standards consistent, and provide quick customer service. To keep up with production schedules, delivery reliability becomes very important, so choosing a supplier partnership is a strategic thing to think about.

Conclusion

That is why you need crucibles made of very pure zirconium (Zr). They smell good, don't react with chemicals, and keep germs out, so they're the best on the market. These machines make it possible for businesses to make consistent products. They also make business safer. This is possible because they are friendly and helpful, and they choose and stay in touch with the right suppliers. Long-term goals can be reached by people who buy these things if they know what they can do and how to use them. You can get more use out of your tools, keep them clean, and make them last longer if you buy good zirconium crucibles.

FAQ

Q1: What temperature range can high-purity zirconium crucibles safely operate within?

A: High-purity zirconium crucibles can safely operate at temperatures up to 1,850°C (3,362°F). This exceptional temperature resistance makes them ideal for semiconductor crystal growth processes and high-temperature material purification applications. The crucibles maintain structural integrity throughout the entire temperature range when proper heating and cooling procedures are followed.

Q2: How do zirconium crucibles compare to graphite alternatives in semiconductor manufacturing?

A: Zirconium crucibles offer superior chemical inertness and contamination control compared to graphite alternatives. While graphite crucibles may introduce carbon contamination into processed materials, zirconium maintains chemical neutrality throughout processing. Additionally, zirconium crucibles demonstrate longer service life and better corrosion resistance against acids and alkalis commonly used in semiconductor processing.

Q3: What factors determine the appropriate wall thickness for zirconium crucibles?

A: Wall thickness selection depends on operating temperature, material volume, and mechanical stress requirements. Thicker walls (3-5mm) provide enhanced durability for high-temperature applications and frequent thermal cycling, while thinner walls (1-2mm) offer faster heat transfer for applications requiring rapid temperature changes. Application-specific consultation ensures optimal wall thickness selection for each use case.

Freelong's Zirconium Crucible Solutions Let You Experience Excellence

Baoji Freelong New Material Technology Development Co., Ltd. is a top company that makes zirconium crucibles. We take advantage of our location in China's Titanium Valley to give semiconductor manufacturers around the world the best products. We have a lot of experience working with aerospace, electronics, and research institutions around the world, which has helped us learn more about the specific needs and quality standards of these industries.

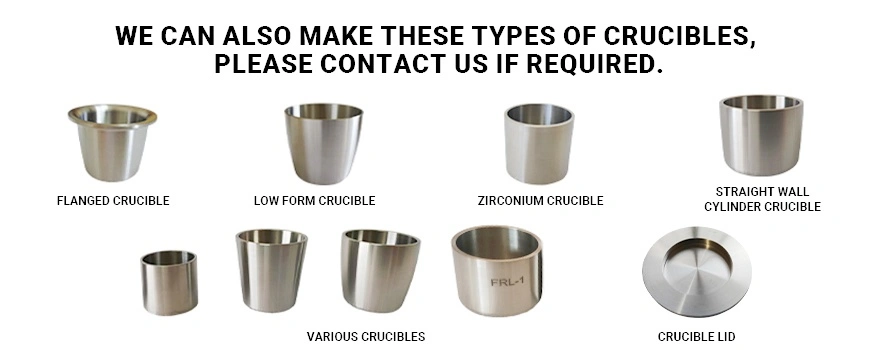

Our manufacturing capabilities include all types of high-purity zirconium crucibles, from 5ml lab units to 5L industrial ones. All of them have smooth surfaces and are 99.2% pure or higher. Custom sizing and specification options can be used for a wide range of applications, and our fast delivery time of 5 to 7 days can meet urgent production needs. Quality assurance protocols make sure that every crucible meets the very high standards of the semiconductor industry.

Working with Freelong has many benefits, not just high-quality products. These benefits also include full technical support and reasonable prices. Our low minimum order quantity of just one piece makes it possible for both small-scale research projects and large-scale production needs. Customers can check the performance of samples before placing larger orders, which lowers the risks of procurement.

Click here to learn more about how our zirconium crucible solutions can help your semiconductor manufacturing processes. You can also email us at jenny@bjfreelong.com to get pricing and more information. Our technical team is ready to help with application-specific advice and the creation of custom solutions. You can find out about all of our high-performance materials and manufacturing options at frlmetal.com.

References

1. Materials Science and Engineering: An Introduction, 10th Edition, by William D. Callister Jr. and David G. Rethwisch

2. Handbook of Refractory Carbides and Nitrides: Properties, Characteristics, Processing, and Applications by Hugh O. Pierson

3. Semiconductor Materials and Device Characterization, 3rd Edition by Dieter K. Schroder

4. High Temperature Materials and Mechanisms by Yoseph Bar-Cohen

5. Crystal Growth Technology: From Fundamentals and Simulation to Large-scale Production by Peter Rudolph

6. Corrosion Resistance of Zirconium and Its Alloys in Chemical Processing Environments by ASTM International Standards

_1769764373718.png)

_1744873211340.webp)

_1745572620134.webp)

_1745392624503.webp)