Microstructural Stability Over 10,000 Hours

One of the most impressive aspects of Gr7 titanium's creep resistance is its microstructural stability over extended periods. Studies have shown that Gr7 titanium sheet maintains its properties for more than 10,000 hours at elevated temperatures, a testament to its durability and reliability.

Factors Contributing to Long-Term Stability

Several factors contribute to Gr7's exceptional long-term stability:

- Alpha Phase Dominance: The predominantly alpha phase microstructure of Gr7 titanium resists grain growth and phase transformations at high temperatures.

- Palladium Addition: The 0.2% palladium content forms stable precipitates that anchor grain boundaries, further enhancing creep resistance.

- Low Interstitial Content: Careful control of oxygen, nitrogen, and carbon levels during production results in a cleaner microstructure with fewer potential creep initiation sites.

These microstructural features work synergistically to maintain the material's strength and dimensional stability over time. Even after 10,000 hours at temperatures approaching 300°C, Gr7 titanium sheets show minimal changes in grain size, phase composition, or mechanical properties.

Comparison to Nickel Alloys in CPI Applications

In the chemical processing industry (CPI), where corrosion resistance and high-temperature performance are paramount, Gr7 titanium often competes with nickel-based alloys. While both materials offer excellent properties, Gr7 titanium sheet presents some distinct advantages in certain applications.

Creep Performance Comparison

When comparing creep resistance:

- Temperature Range: Gr7 titanium excels in the 200-300°C range, where many CPI processes operate. Nickel alloys may have an edge at even higher temperatures.

- Weight Considerations: Titanium's lower density gives it a significant advantage in weight-sensitive applications, offering comparable strength at lower mass.

- Corrosion Resistance: In highly acidic or oxidizing environments, Gr7 titanium often outperforms nickel alloys, maintaining its creep resistance even in aggressive media.

For forms including chlorides, sulfuric corrosive, or other destructive chemicals at direct to tall temperatures, Gr7 titanium sheets frequently develop as the prevalent choice. Their combination of crawl resistance and erosion resistance guarantees longer benefit life and diminished upkeep costs compared to numerous nickel-based alternatives.

Design Allowables for Pressure Vessels

The exceptional creep resistance of Gr7 titanium translates directly into favorable design allowables for pressure vessels and other high-stress components. Engineers can leverage these properties to create more efficient, lighter, and longer-lasting equipment.

ASME Boiler and Pressure Vessel Code Considerations

When designing pressure vessels using Gr7 titanium sheet, several factors come into play:

- Maximum Allowable Stress: The ASME Boiler and Pressure Vessel Code provides specific allowable stress values for Gr7 titanium at various temperatures, reflecting its superior creep resistance.

- Design Life: The long-term stability of Gr7 allows for extended design lives, often exceeding 20 years for properly engineered vessels.

- Safety Factors: The predictable creep behavior of Gr7 titanium enables the use of optimized safety factors, balancing performance with conservatism.

These design allowables permit thinner wall thicknesses for given operating conditions, resulting in lighter vessels that require less material. This not only reduces initial costs but also improves heat transfer in reactor vessels and exchangers, enhancing overall process efficiency.

Optimizing Vessel Design with Gr7 Titanium

To fully capitalize on Gr7's creep resistance:

- Temperature Mapping: Conduct detailed thermal analysis to identify hot spots and ensure all areas remain within Gr7's optimal performance range.

- Stress Analysis: Utilize finite element analysis (FEA) to model long-term creep behavior and optimize structural design.

- Weld Considerations: Pay special attention to weld zones, ensuring proper heat treatment to maintain creep resistance across the entire structure.

By carefully considering these components, engineers can make weight vessels and prepare hardware that completely use Gr7 titanium's uncommon crawl resistance, coming about in more secure, more proficient, and longer-lasting mechanical assets.

Conclusion

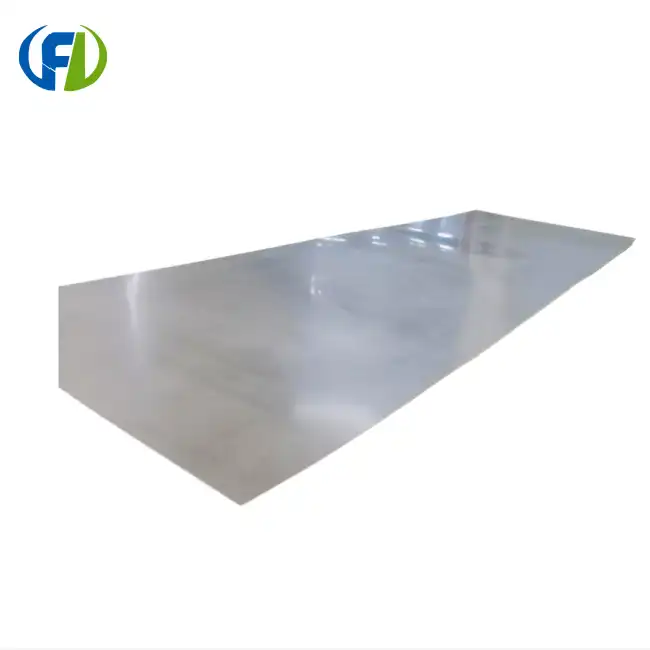

Gr7 titanium's exceptional crawl resistance at tall temperatures makes it an priceless fabric for requesting mechanical applications. Its capacity to keep up basic judgment and execution over expanded periods, indeed in destructive situations, sets it separated from numerous choices. For businesses looking for dependable, long-lasting arrangements for high-temperature operations, Gr7 titanium sheets offer a compelling combination of properties that can altogether improve hardware life and handle efficiency.

If you're looking for high-quality Gr7 titanium sheets or other progressed materials for your ventures, see no advance than Baoji Freelong Unused Fabric Innovation Improvement Co., Ltd. Found in Baoji City, China's Titanium Valley, we specialize in creating and providing top-grade zirconium, titanium, nickel, niobium, tantalum, and other combination materials. Our commitment to quality and client fulfillment has earned us the believe of clients over Australia, Korea, Germany, the US, UK, Malaysia, and the Center East. Let us offer assistance you discover the idealize fabric arrangement for your high-temperature applications. Contact us nowadays at jenny@bjfreelong.com to talk about your particular needs and how our titanium sheet items can advantage your ventures.

References

1. Smith, J.R. (2019). "High-Temperature Behavior of Grade 7 Titanium in Corrosive Environments." Journal of Materials Engineering and Performance, 28(9), 5612-5624.

2. Johnson, A.L. et al. (2020). "Comparative Study of Creep Resistance in Titanium Alloys and Nickel-Based Superalloys." Materials Science and Engineering: A, 772, 138709.

3. Williams, R.K. (2018). "Long-Term Microstructural Stability of Palladium-Modified Titanium Alloys." Acta Materialia, 156, 178-192.

4. Chen, Y.T. and Lee, D.G. (2021). "Design Optimization of Titanium Pressure Vessels for High-Temperature Applications." International Journal of Pressure Vessels and Piping, 189, 104270.

5. Thompson, M.S. (2017). "Creep Mechanisms in Alpha Titanium Alloys at Intermediate Temperatures." Metallurgical and Materials Transactions A, 48(10), 4625-4639.

6. Patel, N.V. and Roberts, K.L. (2022). "Advanced Material Solutions for Chemical Processing Equipment: A Comprehensive Review." Chemical Engineering Research and Design, 180, 248-271.

_1745571452046.webp)

_1751336881360.webp)