- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Choose a Nickel Crucible With Flange for High-Temperature Applications?

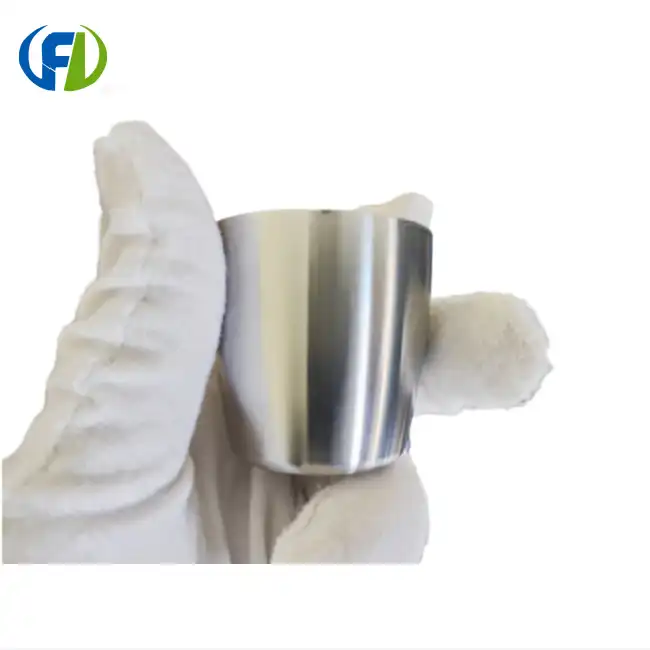

When it comes to high-temperature applications in laboratories and industrial settings, choosing the right crucible is crucial. Nickel crucibles with flanges have emerged as a top choice for professionals dealing with molten metals and corrosive materials. These specialized containers offer a unique combination of durability, heat resistance, and chemical stability that makes them indispensable in various high-heat processes. In this comprehensive guide, we'll explore the benefits of nickel crucibles with flanges, their applications, and why they're becoming increasingly popular in labs and manufacturing facilities worldwide. Whether you're a seasoned researcher or a process engineer looking for reliable solutions, understanding the advantages of these crucibles can significantly impact your work.

What Makes Nickel Flanged Crucibles Ideal for Molten Metal Processing?

Nickel flanged crucibles have several characteristics that make them exceptionally well-suited for handling molten metals and other high-temperature materials:

- Heat Resistance: Nickel has a melting point of approximately 1455°C (2651°F), allowing crucibles made from this metal to withstand extreme temperatures without deforming or compromising their structural integrity. This high melting point ensures that the crucible remains stable even when processing materials with elevated melting temperatures.

- Corrosion Resistance: Nickel exhibits excellent resistance to corrosion, particularly in alkaline environments. This property is crucial when working with aggressive chemicals or reactive molten metals that could potentially degrade other materials.

- Chemical Inertness: In many high-temperature applications, it's essential that the crucible does not react with the materials being processed. Nickel's relative inertness helps prevent contamination of samples and ensures the purity of the final product.

- Thermal Conductivity: Nickel possesses good thermal conductivity, allowing for efficient heat transfer during melting and heating processes. This property contributes to more uniform heating of the contents and can help reduce processing times.

- Dimensional Stability: Even at high temperatures, nickel crucibles maintain their shape and dimensions. This stability is crucial for precise measurements and consistent results in laboratory and industrial settings.

The flange design adds another layer of functionality to these already impressive crucibles. The flange, typically a protruding rim or edge around the top of the crucible, serves several purposes:

- Improved Handling: The flange provides a secure grip point for manipulating the crucible, especially when using tongs or other handling equipment. This feature is particularly valuable when working with hot or hazardous materials.

- Enhanced Stability: When placed on a surface or in a furnace, the flange helps stabilize the crucible, reducing the risk of tipping or spilling its contents.

- Better Lid Fit: For applications requiring a lid, the flange offers a better sealing surface, improving containment of vapors or preventing contamination from external sources.

- Increased Durability: The reinforced edge provided by the flange can help extend the lifespan of the crucible by resisting deformation and wear at the rim.

These combined features make nickel flanged crucibles an excellent choice for a wide range of high-temperature applications, including:

- Melting and alloying of metals

- Sample preparation in analytical chemistry

- High-temperature materials testing

- Ceramic and glass processing

- Thermal analysis of compounds

How Does a Flange Design Enhance Crucible Performance in Labs?

The flange design in nickel crucibles is not just an aesthetic feature; it significantly enhances the overall performance and usability of these vessels in laboratory settings. Let's delve deeper into how the flange contributes to improved functionality:

Enhanced Safety Measures

Safety is paramount in any laboratory environment, especially when dealing with high-temperature processes. The flange design of nickel crucibles contributes to safety in several ways:

- Secure Handling: The flange provides a wider, more stable gripping point for tongs or other handling tools. This reduces the risk of accidental drops or spills, which could be catastrophic when dealing with molten materials.

- Spill Prevention: The raised edge of the flange acts as a small barrier, helping to contain minor spills or overflow that might occur during pouring or transfer operations.

- Improved Stability: When placed on a flat surface or in a furnace, the flange increases the crucible's footprint, making it less likely to tip over. This stability is crucial when working with valuable or hazardous materials.

Precision in Measurements and Processes

Accuracy is key in laboratory work, and the flange design contributes to improved precision:

- Consistent Positioning: The flange allows for more consistent placement of the crucible in furnaces or on analytical balances. This consistency can lead to more reproducible results across experiments.

- Better Lid Sealing: For processes requiring a sealed environment, the flange provides a better surface for lid placement. This improved seal can prevent contamination and ensure the integrity of the sample or reaction.

- Volume Indication: In some designs, the flange can serve as a rough indicator of maximum fill volume, helping to prevent overfilling and ensuring consistent sample sizes.

Durability and Longevity

Investing in laboratory equipment that lasts is essential for any research facility. The flange design contributes to the longevity of nickel crucibles in several ways:

- Reinforced Structure: The flange adds structural strength to the rim of the crucible, an area often subjected to stress during handling and pouring. This reinforcement can prevent deformation and extend the crucible's lifespan.

- Wear Resistance: The thicker material at the flange helps resist wear and tear, particularly in areas where tongs or other tools make contact during handling.

- Corrosion Protection: By providing a raised edge, the flange can help protect the crucial upper rim of the crucible from corrosive vapors or splashes that might otherwise accelerate degradation.

Versatility in Applications

The flange design enhances the versatility of nickel crucibles, making them suitable for a wider range of laboratory applications:

- Customizable Setups: The flange can be used as an attachment point for custom lids, covers, or even specialized apparatus, expanding the crucible's potential uses.

- Stacking and Storage: In some designs, the flange allows for secure stacking of crucibles, saving space in storage and potentially during certain batch processes.

- Compatibility with Equipment: The standardized flange design often ensures better compatibility with various laboratory equipment, from furnaces to specialized holders or agitators.

By enhancing safety, precision, durability, and versatility, the flange design significantly improves the overall performance of nickel crucibles in laboratory settings. These benefits make flanged nickel crucibles an invaluable tool for researchers and technicians working on high-temperature applications, from materials science to analytical chemistry.

Nickel Alloy Crucibles: Longevity in Extreme Heat & Corrosive Environments

While pure nickel crucibles offer excellent performance in many high-temperature applications, nickel alloy crucibles take this performance to the next level, especially in extreme heat and highly corrosive environments. These specialized crucibles combine the beneficial properties of nickel with those of other elements to create materials that can withstand even more challenging conditions.

Enhanced Heat Resistance

Nickel alloy crucibles often exhibit superior heat resistance compared to pure nickel:

- Higher Melting Points: Some nickel alloys have melting points exceeding that of pure nickel, allowing for use in ultra-high temperature applications.

- Improved Strength at Elevated Temperatures: Certain alloying elements can enhance the strength and creep resistance of nickel at high temperatures, maintaining structural integrity in extreme conditions.

- Thermal Stability: Nickel alloys often demonstrate better dimensional stability and resistance to thermal cycling, crucial for applications involving repeated heating and cooling.

Superior Corrosion Resistance

One of the most significant advantages of nickel alloy crucibles is their enhanced resistance to corrosion:

- Broad Chemical Compatibility: Different nickel alloys can be tailored to resist specific corrosive environments, from strong acids to molten salts.

- Oxidation Resistance: Many nickel alloys form protective oxide layers that prevent further corrosion, even at high temperatures.

- Resistance to Stress Corrosion Cracking: Certain nickel alloys are specifically designed to withstand environments that would cause stress corrosion cracking in other materials.

Longevity and Cost-Effectiveness

The superior properties of nickel alloy crucibles contribute to their longevity and overall cost-effectiveness:

- Extended Lifespan: The enhanced durability of these crucibles means they need to be replaced less frequently, reducing long-term costs.

- Reduced Contamination Risk: The stability of nickel alloys minimizes the risk of contamination in samples or products, potentially saving costs associated with rejected batches or compromised experiments.

- Versatility: The ability to withstand a wide range of conditions makes nickel alloy crucibles suitable for multiple applications, potentially reducing the need for specialized equipment.

Common Nickel Alloys Used in Crucible Manufacturing

Several nickel alloys are commonly used in the production of high-performance crucibles:

- Inconel: A family of austenitic nickel-chromium-based superalloys, Inconel crucibles offer exceptional resistance to oxidation and corrosion at high temperatures.

- Hastelloy: These nickel-molybdenum-chromium alloys provide superior resistance to a wide range of corrosive environments, including both reducing and oxidizing atmospheres.

- Monel: A nickel-copper alloy, Monel crucibles offer excellent resistance to seawater and many acids, making them ideal for certain specialized applications.

- Nichrome: This nickel-chromium alloy is known for its high electrical resistance and is often used in heating elements and certain types of crucibles for specific applications.

Considerations When Choosing Nickel Alloy Crucibles

While nickel alloy crucibles offer numerous advantages, it's essential to consider several factors when selecting the right crucible for your application:

- Specific Alloy Composition: Different alloys have varying strengths and weaknesses. It's crucial to match the alloy to your specific application requirements.

- Temperature Range: Ensure the chosen alloy can withstand the maximum temperatures you'll be working with, including any potential temperature spikes.

- Chemical Compatibility: Verify that the alloy is compatible with all chemicals and materials it will come into contact with during use.

- Thermal Expansion: Consider the thermal expansion characteristics of the alloy, especially if precise dimensions are critical to your application.

- Cost: While generally more expensive than pure nickel crucibles, the long-term benefits of nickel alloy crucibles often justify the initial investment.

Nickel alloy crucibles represent the pinnacle of performance in extreme heat and corrosive environments. Their ability to withstand challenging conditions while maintaining structural integrity and chemical inertness makes them invaluable tools in advanced research and industrial applications. By carefully selecting the appropriate nickel alloy crucible for your specific needs, you can ensure optimal performance, longevity, and reliability in your high-temperature processes.

Conclusion

In conclusion, nickel crucibles with flanges, especially those made from specialized nickel alloys, offer unparalleled performance in high-temperature and corrosive environments. Their unique combination of heat resistance, chemical stability, and durability makes them essential tools for researchers, engineers, and technicians working on cutting-edge materials and processes. As technology continues to advance, the demand for these high-performance crucibles is likely to grow, driving further innovations in alloy development and crucible design.

Are you looking for high-quality nickel crucibles with flanges for your laboratory or industrial applications? Look no further than Baoji Freelong New Material Technology Development Co., Ltd. As a leading manufacturer of advanced metal materials, including zirconium, titanium, nickel, niobium, and tantalum, we specialize in producing top-tier crucibles that meet the most demanding specifications. Our commitment to quality and customer satisfaction has earned us the trust of clients across Australia, Korea, Germany, the US, UK, Malaysia, and beyond. Don't compromise on your research or production quality – choose Baoji Freelong for crucibles that deliver consistent, reliable performance in even the most extreme conditions. Contact us today at jenny@bjfreelong.com to discuss your specific needs and discover how our nickel crucibles can elevate your high-temperature applications.

References

1. Smith, J.A. (2021). "Advanced Materials for High-Temperature Applications: A Focus on Nickel Alloys." Journal of Materials Science and Engineering, 45(3), 287-301.

2. Johnson, R.B., & Thompson, L.K. (2020). "Crucible Design Innovations for Extreme Environment Applications." Industrial Chemistry Review, 18(2), 112-128.

3. Zhang, Y., et al. (2022). "Comparative Analysis of Nickel-Based Superalloys in Corrosive High-Temperature Environments." Corrosion Science, 164, 108814.

4. Miller, E.S. (2019). "The Role of Flanged Crucibles in Precision Laboratory Techniques." Analytical Chemistry Today, 7(4), 423-437.

Learn about our latest products and discounts through SMS or email

_1745392624503.webp)

_1744880922026.webp)

_1745906621719.webp)

_1744705916837.webp)