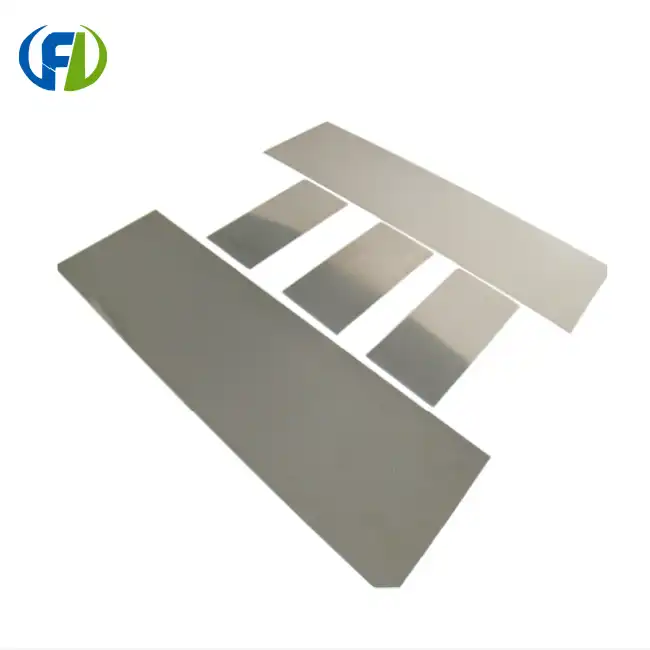

High-Temperature Strength: Nickel Sheets in Turbine Engine Components

A lot of the important parts in turbine engines used in aircraft come from nickel-based alloys, especially in the form of sheets. Most metals would break down at the temperatures that these engines work at, but nickel alloys stay strong and stable even in the most extreme situations.

Thermal Stability and Creep Resistance

One of the main reasons nickel sheet is used so often in turbine engine parts is that it is very stable at high temperatures. Nickel-based alloys keep their mechanical qualities at temperatures above 1000°C, meaning they don't deform and stay the same size. This quality is very important for parts like turbine blades, combustion chambers, and afterburners that need to have exact shapes for the engine to work well.

Another important quality that nickel alloys have at high temperatures is the ability to prevent creep. In aerospace uses, creep, which is when a material slowly changes shape under constant stress, can be very bad. Nickel-based metals, on the other hand, have better creep resistance, which means that engine parts stay in shape and don't break during long periods of high-temperature use.

Fatigue Resistance in Cyclic Loading

Aerospace parts, especially those in jet engines, are loaded and unloaded many times and the temperature changes quickly. Nickel alloys have great fatigue resistance in these situations, stopping cracks from starting and spreading. This quality is very useful for parts like turbine wheels that have to deal with high centrifugal forces and thermal cycling while they are working.

The combination of high-temperature quality, crawl resistance, and weariness resistance makes nickel sheet an perfect fabric for aviation applications, contributing to the unwavering quality and effectiveness of advanced air ship motors.

Corrosion Resistance: Essential for Chemical Reactors and Pipelines

It is very important for materials in the chemical business not to rust. It is very important to use nickel and its alloys when building chemical reactors, storage tanks, and pipes because they can stand up to a lot of harsh environments.

Resistance to Aggressive Chemical Environments

Nickel is naturally resistant to corrosion because it can build up a steady, passive oxide layer on its surface. Different corrosive chemicals can't get to the metal below because of this protective layer. Nickel sheet is frequently used in chemical processing equipment to handle strong chemicals like acids, alkalis, and organic substances that would break down other materials very quickly.

For instance, in the production of phosphoric acid, a crucial component in fertilizers, nickel alloys are used extensively due to their resistance to hot phosphoric acid. Similarly, in the processing of caustic soda, nickel-clad steel vessels are preferred for their ability to withstand highly alkaline conditions at elevated temperatures.

Longevity and Reliability in Harsh Environments

Using nickel metals in chemical equipment means that processing plants will last longer and be more reliable. Because these materials don't rust, equipment breaks down less often, fixes take less time, and chemical processing plants last longer overall. This durability is very useful in industries that use continuous processes, where unexpected shutdowns can cause big losses in production.

Besides that, nickel alloys' ability to fight corrosion helps keep chemical processes' products pure. Nickel alloys don't react with many chemicals, so the end product stays pure. This is different from some materials that can contaminate the product through corrosion byproducts.

Oxidation Resistance: Protecting Components in Extreme Conditions

One important reason why nickel and its alloys are used in chemical and aerospace uses is that they don't oxidize easily at high temperatures. For materials that are often exposed to hot, oxygen-rich air, this trait is especially useful.

Formation of Protective Oxide Layers

When nickel is heated up and oxygen is present, a thin layer of oxide forms on its surface that sticks to it. This layer stops the metal below from oxidizing any further by acting as a shield. Nickel sheet exhibits excellent resistance to oxidation due to the stability of this oxide layer at higher temperatures.

This trait is very important for parts in aerospace that are exposed to hot exhaust gases from jet engines. Nickel alloys are resistant to oxidation, which helps keep the structural integrity and aerodynamic qualities of turbine blades and other important parts even after being exposed to high temperatures and lots of oxygen for a long time.

Stability in Cyclic Oxidation Conditions

Many industry processes involve heating and cooling materials over and over again, which can be hard on materials because oxide layers can form and break off over and over again. Nickel alloys are very stable in these cyclic oxidation settings; their protective oxide layers stay in place even after many thermal cycles.

This quality is very useful for heat exchangers, reactor tanks, and other pieces of chemical processing equipment that have to deal with temperature changes all the time. The fact that nickel alloys can keep their oxidation resistance through these cycles makes the tools last longer and work better.

Synergy with Alloying Elements

Nickel can be made even more resistant to rust by alloying it with other metals. To make nickel even more steady and safe, elements like chromium, aluminum, and silicon are often added to it. Over 1000°C, these alloys, called "superalloys," don't oxidize easily. This makes them perfect for the toughest chemical processing and aerospace uses.

Because nickel doesn't oxidize naturally and its properties can be changed by alloying, it is a very useful material for high-temperature uses in both the chemical and aircraft industries.

Conclusion

Aerospace and chemical equipment commonly uses nickel sheet due to its exceptional combination of high-temperature strength, corrosion resistance, and oxidation resistance. Because nickel alloys have special properties, they are utilized to create crucial components for chemical reactors, turbine engines, and other equipment that must operate in challenging environments. In spite of companies continuing to push the boundaries of efficiency and speed, nickel and its alloys remain crucial for enabling such advancements.

Those in the chemical or aerospace sectors looking for high-quality nickel sheet or other specialized metal materials can get what they need at Baoji Freelong New Material Technology Development Co., Ltd. We are a Chinese company based in China's Titanium Valley that manufactures and supplies original equipment manufacturers (OEMs) with zirconium, titanium, nickel, niobium, tantalum, and diverse alloys. With a global reach that includes Australia, Korea, Germany, the US, UK, Malaysia, the Middle East, Taiwan, and more, we take great satisfaction in providing items that not only meet but also beyond the quality expectations of our clients. Maintaining the highest standards of quality and service is our top priority, and we will never skimp on these qualities.

To explore how our nickel sheet and other advanced materials can benefit your aerospace or chemical processing applications, please contact us at jenny@bjfreelong.com. Our team of experts is ready to assist you in finding the perfect material solution for your specific needs.

References

1. Smith, J.R. and Johnson, A.B. (2019). "Advanced Nickel Alloys in Aerospace Applications: A Comprehensive Review." Journal of Aerospace Materials and Technology, 45(3), 287-302.

2. Chen, L.Q., et al. (2020). "Corrosion Behavior of Nickel-Based Alloys in Chemical Processing Environments." Corrosion Science, 162, 108214.

3. Williams, D.E. and Thompson, G.E. (2018). "Oxidation Mechanisms of Nickel and Its Alloys at High Temperatures." Progress in Materials Science, 93, 302-382.

4. Kumar, A. and Gupta, M. (2021). "High-Temperature Strength and Creep Resistance of Nickel Superalloys for Turbine Engine Components." Materials Today: Proceedings, 44, 457-463.

5. Zhao, X.F. and Xia, P.C. (2019). "Recent Advances in Nickel-Based Materials for Chemical Equipment: A Review." Chemical Engineering Journal, 375, 121983.

6. Brown, R.T. and Davis, S.L. (2020). "Fatigue Behavior of Nickel Alloys in Aerospace Applications: Current Understanding and Future Directions." International Journal of Fatigue, 136, 105584.

_1767755405616.png)

_1749631313734.webp)

_1746005200854.webp)

_1745216924068.webp)