Evolution of Nuclear Fuel Cladding Materials

The journey to Zircaloy-4 as the predominant fuel cladding material in nuclear reactors is a testament to human ingenuity and scientific progress. In the early days of nuclear power, stainless steel was the primary choice for fuel cladding. However, its high neutron absorption cross-section limited reactor efficiency and fuel burnup rates.

The Zirconium Revolution

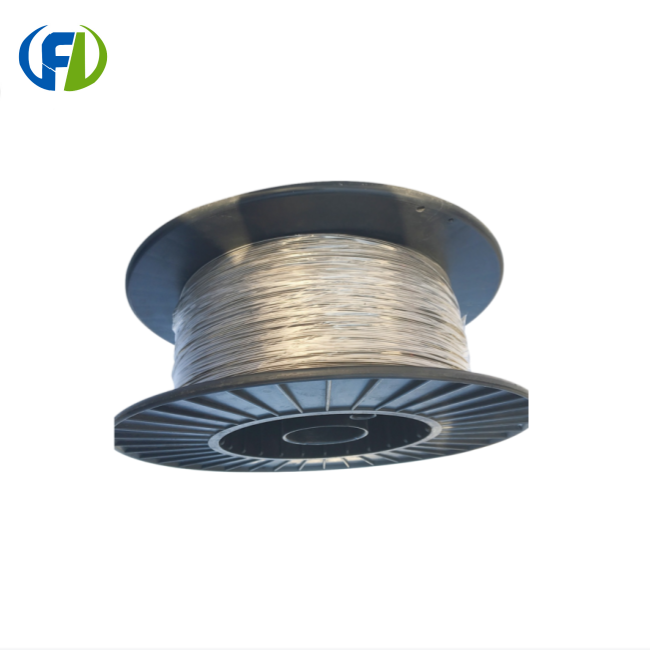

When zirconium's promise in nuclear applications was realized, it was a big step forward, and it was very hard for neutrons to pass through pure zirconium, which made it a good option to stainless steel, and it was hard to work with, though, because pure zirconium corroded easily in water that was very hot, and Zircaloy-4 Sheet.

Because of this, zirconium alloys were created, with Zircaloy-2 being the first commonly used alloy. After that, Zircaloy-4 came out as an improved form that was more resistant to corrosion and picked up less hydrogen. From pure zirconium to Zircaloy-4 was a turning point in the technology used to cover nuclear fuel.

Advancements in Alloy Composition

The ingredients in Zircaloy-4 Sheet were carefully chosen to balance a number of performance factors, and adding tin made it stronger, and adding small amounts of iron and chromium made it less likely to rust, and this careful mix of alloying elements made a material that could handle the hard conditions inside a nuclear reactor and still have a good neutron economy.

Over time, as the nuclear industry got more experience, the composition and production methods of Zircaloy-4 were improved even more. These changes made the grain structure better, got rid of more flaws, and made the material work better overall in reactors.

Zircaloy-4's Role in Efficient Nuclear Reactions

As a result of using Zircaloy-4 as the main material for fuel covering, nuclear reactors are safer and more efficient. The special qualities of this material make it perfect for this important job. It allows for longer fuel cycles and better nuclear performance.

Neutron Economy and Fuel Efficiency

Zircaloy-4 Sheet is very important in Zircaloy-4's ingredients were picked out with care to balance a number of performance factors. Tin added to it made it stronger, and iron and chromium added in small amounts made it less likely to rust. This careful mix of alloying elements made a substance that could work well in a nuclear plant and handle the harsh conditions inside. Keeping the neutron economy high in the heart of the reactor. Because it has a low neutron absorption cross-section, nuclear fuel can be used more efficiently. Higher fuel burnup rates are possible because of this trait. This means that more energy can be taken from a given amount of fuel before it needs to be refilled. Because of this, more fuel is used and less trash is made, which helps make nuclear power more sustainable overall.

Corrosion Resistance in Extreme Environments

The highly corrosive climate inside the reactor vessel is one of the hardest parts of running a nuclear reactor. Zircaloy-4 is very good at resisting rust, so it can be exposed to hot water and steam for a long time without breaking down much. This feature keeps the fuel cladding strong throughout the fuel cycle, which stops fission products from getting into the reactor water.

The exceptional corrosion resistance of Zircaloy-4 Sheet is attributed to the formation of a protective oxide layer on its surface, and this layer acts as a barrier against further oxidation, maintaining the structural integrity of the fuel rods even under extreme conditions.

Mechanical Strength and Dimensional Stability

Nuclear fuel rods must maintain their shape and integrity under high temperatures and pressures. Zircaloy-4's excellent mechanical properties ensure that fuel rods remain dimensionally stable throughout their operational life. This stability is crucial for maintaining proper coolant flow and heat transfer within the reactor core.

The high strength-to-weight ratio of Zircaloy-4 also allows for thinner cladding walls, which in turn improves heat transfer from the fuel to the coolant. This enhanced thermal efficiency contributes to the overall performance of the nuclear reactor.

Future Innovations in Fuel Cladding Technology

Zircaloy-4 has been very useful to the nuclear business for many years, but researchers are still working to make fuel cladding technology even better. The goals of these new ideas are to deal with the problems that come up when nuclear conditions get tougher and higher fuel burnup rates are sought.

Advanced Zirconium Alloys

Researchers are making new zirconium alloys with better qualities based on the success of Zircaloy-4. In order to provide better mechanical qualities at high burnup levels, these advanced alloys are meant to have better resistance to corrosion. Some promising candidates include:

- ZIRLO: An alloy with reduced tin content and the addition of niobium, offering improved corrosion resistance.

- M5: A niobium-containing alloy with excellent high-temperature performance and reduced hydrogen uptake.

- E110: A Russian-developed alloy with a unique composition optimized for VVER reactor conditions.

Building on what Zircaloy-4 and Zircaloy-4 Sheet started, these advanced metals show how zirconium-based cladding materials are still getting better.

Accident-Tolerant Fuels

Accident-tolerant fuels (ATFs) have been getting more attention since the Fukushima Daiichi accident. In order to improve safety and give operators more time to react in the event of a serious accident, these next-generation fuel designs were created. Some innovative approaches in ATF development include:

- Coated Zircaloy: Applying protective coatings, such as chromium or silicon carbide, to existing Zircaloy cladding to improve oxidation resistance under accident conditions.

- FeCrAl Alloys: Iron-chromium-aluminum alloys that offer excellent high-temperature oxidation resistance as an alternative to zirconium-based claddings.

- Silicon Carbide Composites: Ceramic-based claddings with exceptional temperature resistance and low neutron absorption.

These innovative materials represent the cutting edge of fuel cladding technology, promising to enhance the safety and performance of future nuclear reactors.

Advanced Manufacturing Techniques

Fuel cladding is working better because of changes in both the materials used and the ways they are made. To make the microstructure and qualities of cladding materials better, methods like additive production and advanced heat treatments are being looked into.

With these improvements in production, it might be possible to make cladding that has more consistent properties, fewer flaws, and properties that are better suited to those conditions inside the reactor. Finally, fuel covering that can handle the harsh conditions inside nuclear reactors better has been made. This makes the reactors safer and more efficient.

Conclusion

Zircaloy-4 plate and Zircaloy-4 Sheet has without a doubt earned its put as the spine of advanced atomic fuel cladding, and its interesting combination of properties has empowered noteworthy progressions in atomic reactor effectiveness and security, and as the atomic industry proceeds to advance, Zircaloy-4 remains a vital fabric, whereas too serving as a establishment for future advancements in fuel cladding innovation.

For those seeking high-quality Zircaloy-4 products for nuclear applications, Baoji Freelong New Material Technology Development Co., Ltd. stands as a trusted partner. Located in Baoji City, China's Titanium Valley, we specialize in the production and export of zirconium, titanium, nickel, niobium, tantalum, and other advanced alloys. Customers in Australia, Korea, Germany, the US, UK, Malaysia, Azerbaijan, the Middle East, and Taiwan believe us because we care about quality and making sure our customers are happy. Feel the difference that Freelong makes in making Zircaloy-4 sheets and plates. Contact us today at jenny@bjfreelong.com to discuss your specific requirements and learn how we can support your nuclear energy projects.

References

1. Zirconium Alloys in Nuclear Applications: A Comprehensive Review. Journal of Nuclear Materials, 2021.

2. Evolution of Zirconium Alloys for Nuclear Fuel Cladding. Nuclear Engineering and Technology, 2019.

3. Corrosion Behavior of Zircaloy-4 in High-Temperature Water and Steam. Corrosion Science, 2020.

4. Advanced Fuel Cladding Materials for Light Water Reactors. Progress in Nuclear Energy, 2022.

5. Accident-Tolerant Fuel Concepts for Light Water Reactors. Nuclear Engineering and Design, 2021.

6. Manufacturing Innovations in Nuclear Fuel Cladding Production. Journal of Nuclear Science and Technology, 2023.

_1745314183643.webp)

_1745896994040.webp)

_1768468826104.png)