- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

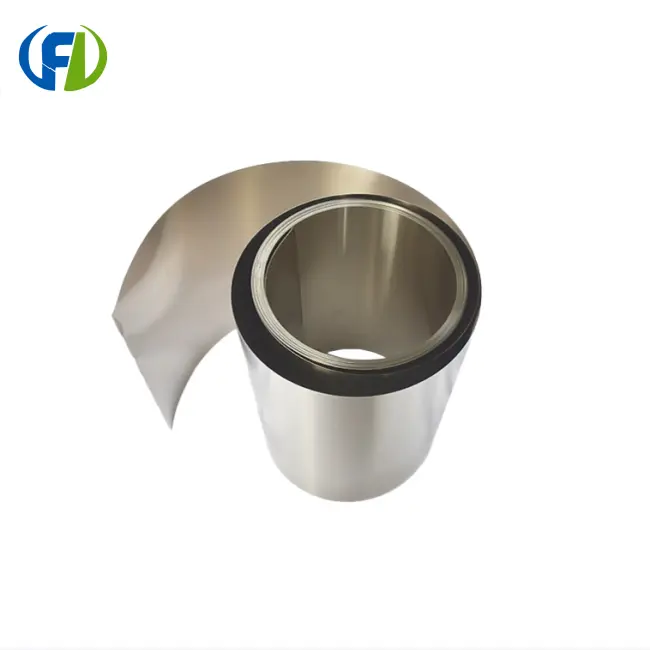

titanium foils

Brand: FRL metal

Density: 4.51g/cm³

Grade: Gr1,Gr2,TA1,TA2.Gr5, Gr7

Standard: ASTM B265 / AMS 4902

Thickness: 0.02mm to 0.3mm Or As Per Customer's Request

Processing technology: cold rolling/hot rolling

Advantages: high strength and corrosion resistance

Certification: ISO9001

Delivery time: 7-15 days

Packaging Details: Plywood case

Premium Titanium Foils - Superior Quality & Custom Solutions

Product Introduction

When you need high-performance metal solutions for demanding applications, our titanium foils deliver exceptional quality and reliability. Located in Baoji City, China's renowned Titanium Valley, Baoji Freelong New Material Technology Development Co., Ltd. specializes in producing premium titanium foils that meet the strictest industry standards. Our advanced manufacturing capabilities and decades of expertise ensure you receive products that exceed your expectations every time.

Our titanium foils are engineered for versatility and performance. We offer comprehensive thickness ranges from ultra-thin 0.01mm to robust 1.0mm, with widths extending up to 1000mm. This flexibility allows you to find the perfect solution for your specific project requirements. Whether you're working in aerospace, medical devices, or chemical processing, our products provide the durability and precision you demand.

|

|

|

Chemcial Composition Of ASTM B265 Titanium Foil/Strip:

| Element | Composition,% | |||||||||

| Grade1 | Grade2 | Grade3 | Grade4 | Grade5 | Grade6 | Grade7 | Grade9 | Grade11 | Grade12 | |

| N max | 0.03 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| C max | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| H max | 0.05 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| Fe max | 0.2 | 0.3 | 0.3 | 0.5 | 0.4 | 0.3 | 0.5 | 0.25 | 0.2 | 0.3 |

| O max | 0.18 | 0.25 | 0.35 | 0.4 | 0.2 | 0.2 | 0.25 | 0.15 | 0.18 | 0.25 |

| Al | 5.5-6.75 | 4.0-4.6 | 2.5-3.5 | |||||||

| V | 3.5-4.5 | 2.0-3.0 | ||||||||

Technical Specifications

Available Grades:

- GR1: Pure titanium with excellent corrosion resistance

- GR2: Commercial pure titanium for general applications

- GR5: Titanium alloy (Ti-6Al-4V) for high-strength requirements

- GR7: Enhanced corrosion resistance for harsh environments

Dimensions:

- Thickness: 0.01mm to 1.0mm

- Width: Up to 1000mm

- Length: Customizable based on your requirements

Surface Finish Options:

- Polished finish for smooth applications

- Pickled surface for enhanced adhesion properties

Key Features and Benefits

Superior Corrosion Resistance

Your projects benefit from titanium's natural resistance to acids, seawater, and harsh chemicals. This means longer service life and reduced maintenance costs.

Exceptional Flexibility

Our thin foils maintain structural integrity while offering excellent formability. You can shape and manipulate them without compromising strength.

Lightweight Yet Strong

Titanium's high strength-to-weight ratio makes it perfect for applications where weight reduction is crucial without sacrificing performance.

Temperature Stability

These materials perform consistently across wide temperature ranges, making them suitable for extreme operating conditions.

Applications and Industries Served

Chemical Processing

Heat exchangers, reaction vessels, and piping systems benefit from titanium's chemical inertness.

Electronics Industry

Circuit boards, connectors, and shielding applications utilize titanium's electrical properties and durability.

Marine Applications

Shipbuilding, offshore platforms, and desalination equipment rely on superior seawater resistance.

Medical Devices

Biocompatible properties make our foils ideal for implants, surgical instruments, and diagnostic equipment.

Aerospace Components

Aircraft parts, engine components, and satellite systems demand the reliability our products provide.

Manufacturing Process

Our production facility employs state-of-the-art rolling technology to achieve precise thickness control. We start with high-quality titanium ingots, carefully processed through multiple rolling stages. Each step is monitored to ensure consistent quality and dimensional accuracy.

Cold rolling techniques allow us to achieve ultra-thin gauges while maintaining material properties. Our controlled atmosphere processing prevents contamination, ensuring pure metal characteristics throughout production.

Quality Control and Testing

Every batch undergoes rigorous testing protocols. We verify chemical composition, mechanical properties, and surface quality before shipment. Our quality management system ensures traceability from raw materials to finished products.

Testing includes tensile strength analysis, corrosion resistance evaluation, and dimensional verification. This comprehensive approach guarantees you receive materials that meet or exceed specified requirements.

OEM & Customization Services

Your unique requirements deserve tailored solutions. We offer comprehensive customization services including specific dimensions, special grades, and unique packaging requirements. Our engineering team works closely with you to develop products that meet exact specifications.

From prototype development to full-scale production, we support your project at every stage. Our flexible manufacturing capabilities accommodate both small specialty orders and large volume requirements.

FAQs

Q: What minimum order quantities do you require?

A: We accommodate orders of various sizes. Contact us to discuss your specific requirements and volume needs.

Q: Can you provide custom alloy compositions?

A: Yes, our metallurgy expertise allows us to develop special compositions for unique applications.

Q: What lead times should I expect?

A: Standard products typically ship within 2-3 weeks. Custom orders may require additional time depending on specifications.

Q: Do you provide material certificates?

A: Yes, we supply complete material certification including chemical analysis and mechanical properties documentation.

Contact Information

Ready to discuss your titanium foils requirements? Our team is here to help you find the perfect solution.

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Whether you need technical specifications, pricing information, or custom solutions, we're committed to providing the expertise and quality you deserve. Contact us today to discover how our premium titanium foils can enhance your next project.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745891513993.webp)

_1745831318038.webp)

_1758682857884.png)