- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

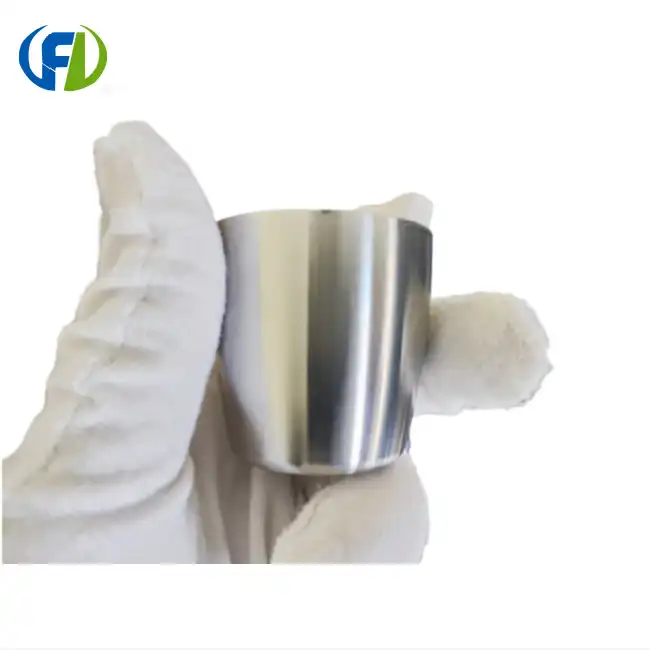

702 Zirconium Crucible With Flange

Brand: FRL Metal

Density: 6.51 g/cm³

Minimum Order Quantity: 1pc Shape: can be customized according

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Certification: ISO9001

Chemical Composition:Zr ≥ 97%, Hf ≤ 4.5%

Introduction to 702 Zirconium Crucible with Flange

702 Zirconium Crucible with Flange has become the first choice for high-temperature smelting and chemical reaction vessels due to its excellent high temperature resistance, corrosion resistance and chemical stability. It is widely used in high-temperature metallurgy, nuclear industry, chemical industry and aerospace, etc., while ensuring high-purity smelting materials, it also greatly improves production efficiency and experimental reliability. With the continuous advancement of technology, the application scope and use effect of 702 Zirconium Crucible with Flange will be more extensive and significant.

| Name | 702 Zirconium Crucible With Flange |

| Material | Zirconium & Zirconium alloy |

| Grade | Zr702,Zr705,RO60001,RO60901 |

| Purity | ≥99.95% |

| Melting point | about 1855℃ (pure zirconium) |

| Density | 6.51 g/cm³ |

| Type | Low form zirconium crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible. |

| Capacity | 50ml, We can also produce and design these volume 5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml etc. |

| Wall thickness | 1mm,2mm,or custom. |

| Custom | Yes, process as per customer's drawing. |

| Oxidation resistance | stable in high temperature oxidation environment |

| Working temperature | recommended below 1700℃. |

| Corrosion resistance | good stability in strong acid, strong alkali and other chemical reagents. |

| Thermal shock resistance | good thermal shock resistance, can adapt to rapid cooling and heating. |

| Service life: | A crucible with a wall thickness of 2mm has a longer service life than a thin-walled crucible and can be used repeatedly for more than 100 times. |

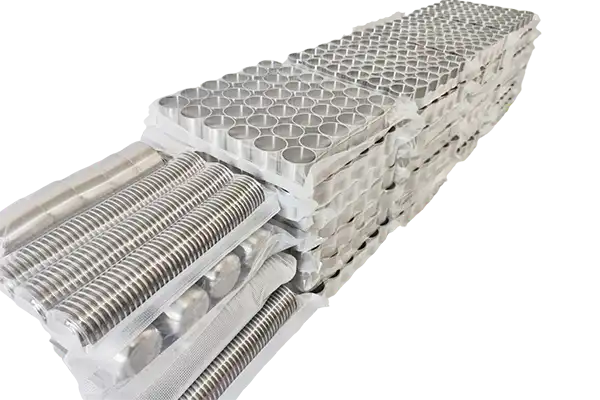

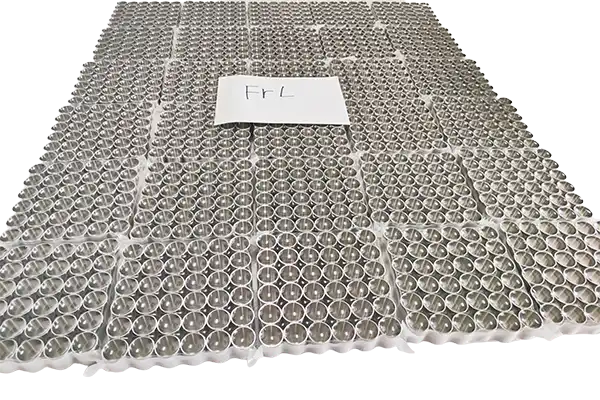

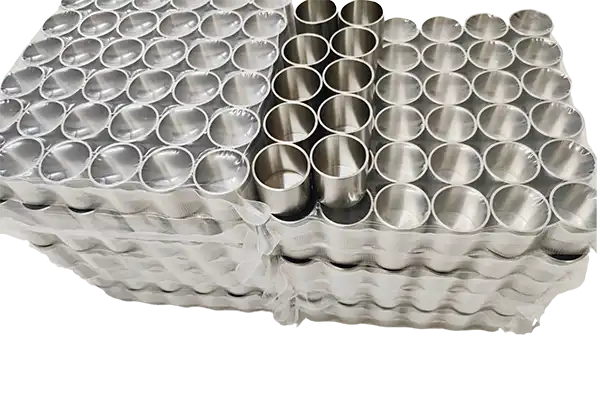

702 Zirconium Crucible With Flange picture display

|

|

|

Advantages of 702 Zirconium Crucible with Flange

1. High temperature resistance: 702 Zirconium Crucible with Flange has an extremely high melting point (1855°C) and is not easy to deform and decompose in a high temperature environment.

2. Corrosion resistance: It has excellent corrosion resistance to various acids, alkalis and salt solutions, especially hydrochloric acid, sulfuric acid and hydrofluoric acid.

3. Chemical stability: It does not react with various substances at high temperatures, ensuring the purity of the smelting material.

4. High mechanical strength: It can still maintain good mechanical properties under high temperature environment and is not easy to break.

5. Good thermal conductivity: It ensures uniform heat transfer and improves smelting efficiency.

The quality assurance of 702 zirconium crucible with flange is mainly reflected in the following aspects:

1. Raw material control: We use high-purity 702 zirconium material to ensure the high quality and stable performance of the material.

2. Production process: We use advanced production technology and equipment to strictly control each production process to ensure the dimensional accuracy and surface finish of the crucible.

3. Quality inspection: We carry out strict quality inspection during the production process, including chemical composition analysis, mechanical property testing and dimensional inspection, to ensure that each crucible meets the technical standards.

4. Packaging and transportation: We use shockproof and moisture-proof packaging to ensure the safety of the product during transportation and deliver it to customers intact.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipment

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745396531951.webp)