- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Polished Zirconium Crucible Ø55×55mm

Brand: FRL Metal

Grade: Zr702,Zr705,R60001,R60901

Volume:5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc,

Type: Low form zirconiu crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible

Surface: polished surface

Density: 6.51g/cm3

Minimum Order Quantity:1pc

Sample: available

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Polished Zirconium Crucible Ø55×55mm: High-Purity Precision for Advanced Industries

Baoji Freelong New Material Technology Development Co., Ltd. is a leading manufacturer and supplier of 【Polished Zirconium Crucible Ø55×55mm】. Our expertly crafted crucibles offer unparalleled purity, precision, and durability for demanding applications in semiconductor, aerospace, and research sectors. With our advanced manufacturing capabilities and strict quality control, we ensure each crucible meets the highest industry standards.

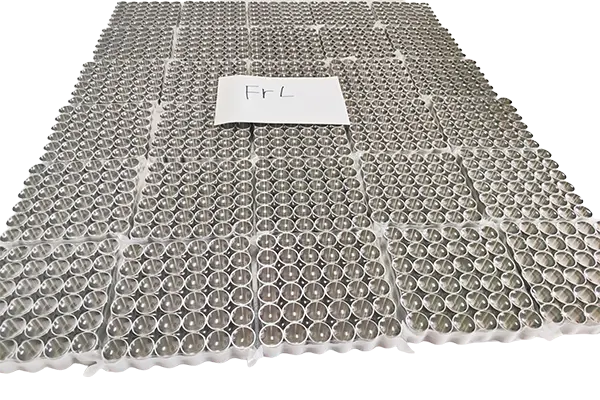

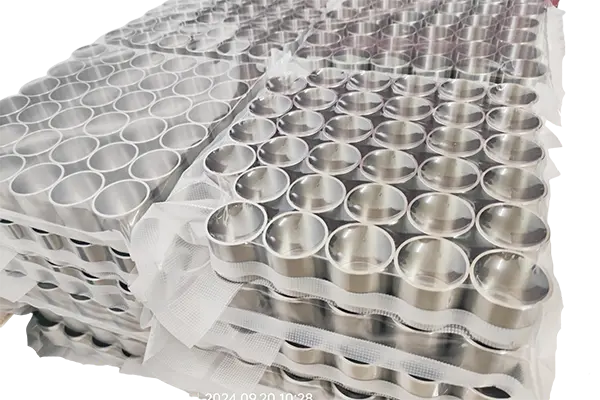

Polished Zirconium Crucible Ø55×55mm picture display

|

|

|

Product Introduction

Our 【Polished Zirconium Crucible Ø55×55mm】 is a premium-grade container designed for high-temperature, corrosive environments. Crafted from high-purity zirconium, this crucible offers exceptional resistance to thermal shock and chemical reactions, making it ideal for crystal growth, metal melting, and advanced material processing.

Technical Specifications

- Material: High-purity zirconium (Zr702 or custom grade)

- Dimensions: Ø55×55mm (±0.5mm tolerance)

- Surface Finish: Polished to Ra ≤ 0.4μm

- Purity: 99.9% (customizable up to 99.999%)

- Maximum Operating Temperature: 1,800°C

- Hardness: 200 HV

Key Features and Benefits

- Superior Corrosion Resistance: Withstands aggressive chemicals and molten metals.

- Excellent Thermal Stability: Maintains structural integrity at extreme temperatures.

- High Purity: Minimizes contamination in sensitive processes.

- Precision-Polished Surface: Ensures easy release and cleaning of materials.

- Customizable Dimensions: Available in various sizes to suit specific applications.

Applications and Industries Served

- Semiconductor Manufacturing: Crystal growth and wafer production

- Aerospace: High-temperature alloy development

- Research Laboratories: Material science experiments and analysis

- Chemical Processing: Handling of reactive substances

Manufacturing Process

Our 【Polished Zirconium Crucible Ø55×55mm】 undergoes a rigorous production process:

- Raw Material Selection: Only the highest-grade zirconium is sourced.

- Precision Machining: CNC turning and milling for exact dimensions.

- Surface Polishing: Multi-stage process to achieve mirror-like finish.

- Heat Treatment: Optimizes material properties for high-temperature use.

- Final Inspection: Dimensional and surface quality checks.

Quality Control and Testing

Every crucible undergoes stringent quality assurance:

- X-ray fluorescence (XRF) analysis for material composition

- Optical emission spectroscopy for trace element detection

- Surface roughness measurements

- Dimensional accuracy verification

- Hydrostatic pressure testing for leak detection

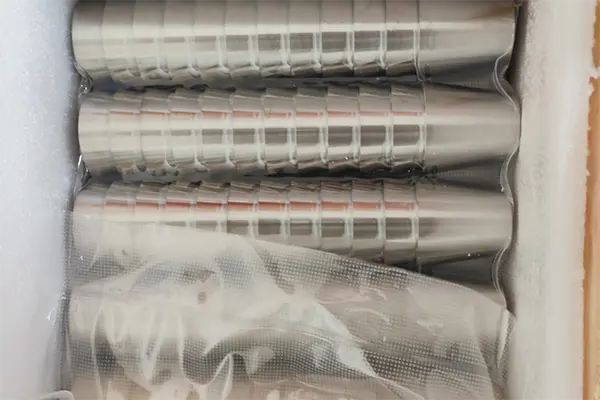

Packaging and Shipping

Our crucibles are carefully packaged to ensure safe transport:

- Individual foam-lined protective cases

- Vacuum-sealed in inert gas for long-term storage

- Shock-absorbing outer packaging for international shipping

- Full documentation and material certificates included

Why Choose Us

- Industry Expertise: Over a decade of experience in zirconium processing.

- Customization Capabilities: Tailored solutions for unique requirements.

- Consistent Quality: ISO 9001 certified manufacturing processes.

- Global Reach: Trusted by leading companies worldwide.

- Competitive Pricing: Direct manufacturing ensures best value.

OEM & Customization Services

We offer full OEM and customization services:

- Custom dimensions and shapes

- Specific material grades and purity levels

- Surface treatments and coatings

- Integrated assemblies and fixtures

Certifications and Compliance

- ISO 9001:2015 Quality Management System

- RoHS and REACH compliant

- ASTM B551 material standard adherence

- Conflict-free material sourcing

Customer Reviews and Case Studies

"Freelong's zirconium crucibles have significantly improved our crystal growth yields." - Leading Semiconductor Manufacturer

"Exceptional purity and consistency batch after batch." - Aerospace R&D Laboratory

FAQs

Q: What is the typical lead time for a 【Polished Zirconium Crucible Ø55×55mm】?

A: Standard sizes are usually available within 2-3 weeks. Custom orders may take 4-6 weeks.

Q: Can you provide material certificates with each order?

A: Yes, we provide full material traceability and test certificates with every shipment.

Q: Is your zirconium sourced ethically and sustainably?

A: Absolutely. We only partner with certified suppliers who adhere to strict ethical and environmental standards.

Q: Do you offer sample crucibles for testing?

A: Yes, we can provide sample crucibles for evaluation. Please contact our sales team for details.

Contact Information

Ready to elevate your high-temperature processes with our premium 【Polished Zirconium Crucible Ø55×55mm】? Contact our expert team today for quotes, technical support, or custom requirements.

Email: jenny@bjfreelong.com

WhatsApp: +86 13571190943

Baoji Freelong New Material Technology Development Co., Ltd. - Your Trusted Partner for Advanced Zirconium Solutions.

Our Packaging

About us

Baoji Freelong New Material Technology Development Co., Ltd loated in Baoji City--China's Titanium Valley,we are mainly doing Zirconium,Titanium,Nickel,Niobium,Tantalum etc metal material and other alloy's produce,OEM and Sales.and also exporting the goods what we make. we have a lot of trustful clients and partner.and also we were authority by some firms.At present,we were build our relationship with Australia,Korea,German,US,UK,Malaysia,AZ,Middle East,Taiwan,Etc. Our company always take the quality and service as our responsibility,We always get close even match the quality what our customer wanted and as for quality,we never say no and no reason for quality failure.

Our Factory

|

|

|

|

|

Production Equipmenty

Testing Equipment

WhatsApp&Wechat: 86 13571190943

E-mail:jenny@bjfreelong.com

Address: No.188. Gaoxin Ave, Baoji City, Shannxi, China.

Learn about our latest products and discounts through SMS or email

_1745218074088.webp)

_1762418302089.webp)

_1745395351966.webp)

_1745829389116.webp)