Making niobium wire in China has changed a lot over the years, making the country a world leader in making high-performance hard metals. The 10 best OEM/ODM niobium wire makers for 2025 are those that are very good at precise engineering, quality control, and coming up with new technologies. These companies make important things for fields like aerospace, electronics, medical devices, and superconductor uses. Each company has its own skills when it comes to manufacturing, product specifications, and providing great customer service. From Baoji's titanium valley to specialized factories all over China, these companies use cutting-edge metallurgy methods and strict quality controls to make niobium wire goods that meet international standards such as ASTM B392-98. Knowing what they can do helps procurement professionals make smart choices for the unique uses that need high-temperature performance and better corrosion resistance.

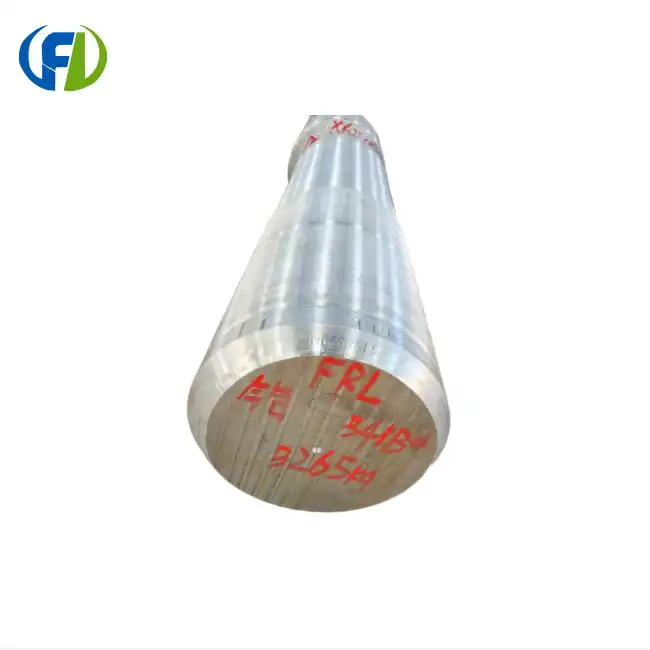

1. Baoji Freelong New Material Technology Development Co., Ltd

Freelong is a top company that makes hard metals and specializes in niobium wire. It is based in Baoji City, which is in China's Titanium Valley. The business makes niobium wire of grades RO4200 and RO4210, with sizes between 0.25mm and 3mm. These wires meet ASTM B392-98 standards and are at least 99.9% or 99.95% pure. Their ISO9001 approval makes sure that quality control is always done right. Modern cold-drawing and precise heating methods make the wire more flexible and strong when pulled apart. Freelong makes high-purity conductors and materials that are light, don't rust, and are used in industries like electronics and aircraft. Their shipping time of 5–7 days shows that they are good at making things and keeping track of their stock. In the global refractory metals market, the company has made strong relationships with clients in Australia, Korea, Germany, the US, the UK, Malaysia, and the Middle East. This has helped it become known as a reliable supplier. Their yearly production capacity is higher than the norm in the industry, and they can meet the needs of both small research projects and big industrial uses.

2. Western Metal Materials Co., Ltd

Western Metal Materials is a company in Shaanxi Province that makes niobium wire for uses in superconductivity. The company makes ultra-high purity grades that are important for medical imaging and quantum studies. Their state-of-the-art vacuum melting facilities keep things clean, and their full-service quality control labs make sure that tests are done correctly. Niobium wire is very resistant to heat and rust, which makes it perfect for use in chemical processing and spacecraft. They can produce a lot of goods every year and sell them in both the United States and other countries. Their own special cold-working methods make wire more flexible without lowering its conductivity. The company works with electronics and medical products, and its main goal is to create new alloys that can be used in renewable energy systems.

3. Baoji Titanium Industry Co., Ltd

Baoji Titanium Industry has been working with hard metals for decades and is one of the best at what they do. For better clarity, they use electron beam melting and vacuum arc remelting to make niobium wire. The company has different diameter options that are made for different industry uses. They focus on sustainable and aerospace-compliant manufacturing and are certified with ISO14001 and AS9100. Their niobium wire is perfect for precise electronics because it is easy to weld and has accurate measurements. The company specializes in developing alloys and making custom wire drawing methods, and it works with aerospace and semiconductor companies around the world. The main goal of these research partnerships is to make niobium wires more superconducting for use in future technologies. Strategic marketing networks help them be present in markets in North America, Europe, and the Asia-Pacific region.

4. Northwest Institute for Nonferrous Metal Research

This company focuses on study and combines academic knowledge with the ability to make products for sale. Their niobium wire has better microstructural qualities than others because it was made through advanced metallurgy research. Modern powder metallurgy and wire drawing tools are used by the company. Their niobium wire is very resistant to fatigue and corrosion, and it meets the strict standards for medical implants. Full chemical and mechanical tests are part of quality assurance. They work with aerospace and medical gadget companies around the world to make specialized niobium wire for use in important situations. The center also provides technical support, such as helping with choosing materials and testing their suitability for use. Their patent collection includes new ways to work with wire and heat treat it.

5. Xi'an Rare Metal Materials Institute

The Xi'an Rare Metal Materials Institute is a business and study center that makes high-purity niobium wire. They make sure the materials are very clean by using plasma arc melting and controlled atmosphere processes. Their niobium wire is very important for superconducting magnets and particle reactors. The school is very good at controlling the diameter very precisely, improving the surface finish, and making things conduct electricity better. Their products meet world quality standards and work the same way every time. Custom alloy development and specialized heat treatment methods are some of the things they know how to do. The institute sets guidelines for the quality and performance of niobium wire and works with research institutions and high-tech companies to make them better.

6. Shaanxi Yunzhong Industry Development Co., Ltd

Yunzhong Industry represents emerging excellence in niobium wire manufacturing, combining traditional metallurgy knowledge with modern automation technologies. Their production facility emphasizes environmental sustainability while maintaining high output levels. The company's niobium wire products feature excellent ductility and corrosion resistance properties. Quality control procedures include real-time monitoring of wire drawing parameters and comprehensive testing of finished products. Their manufacturing capabilities support both standard specifications and customer-specific requirements. The company serves automotive electronics manufacturers and renewable energy equipment producers. Investment in advanced manufacturing equipment enables precise control of wire dimensions and surface characteristics. Their technical team provides application engineering support and material selection guidance. Market expansion focuses on emerging applications in electric vehicle battery systems and energy storage technologies.

7. Baoji Unique Titanium Industry Co., Ltd

Unique Titanium Industry has established a strong reputation for producing high-quality niobium wire through innovative manufacturing processes. Their facility incorporates advanced vacuum induction melting and computer-controlled wire drawing systems. The company's products meet strict aerospace industry requirements for strength-to-weight ratio and corrosion resistance. Manufacturing capabilities include specialized annealing processes that optimize niobium wire mechanical properties. Their quality assurance program encompasses statistical process control and customer-specific testing protocols. The company serves international clients in aerospace, medical device, and electronics industries. Technical advantages include proprietary surface treatment methods that enhance wire performance in aggressive environments. Their research and development activities focus on developing new niobium alloy compositions for specialized applications. Export capacity supports global distribution networks across multiple continents.

8. Advanced Refractory Metals Co., Ltd

Advanced Refractory Metals is an expert at making ultra-high purity niobium wire that is used in quantum computers and superconductor technologies. Controlling contamination and managing the exact chemical makeup are important parts of their manufacturing process. The company makes items that are very good at being both superconducting and stable at high temperatures. Clean rooms and high-tech analytical tools are used to check the quality of the products in production sites. Their niobium wire has better regularity in diameter and surface finish, which is important for high-precision electronics. Customers include some of the world's biggest tech companies and study institutions. Focusing on innovation means coming up with new ways to process niobium wire that make it work better. Their technical knowledge helps with making unique products and making sure they work best for specific applications. Strategic partnerships with big electronics and scientific equipment makers are part of having a market presence.

9. Luoyang Advanced Materials Co., Ltd

Luoyang Advanced Materials combines extensive experience in powder metallurgy with modern wire production technologies. Their niobium wire manufacturing process utilizes controlled atmosphere sintering and precision drawing techniques. The company's products feature excellent dimensional tolerance and mechanical property consistency. Quality management encompasses comprehensive incoming material inspection and finished product testing. Their manufacturing capabilities support high-volume production while maintaining strict quality standards. The company serves chemical processing and electronics industries requiring reliable niobium wire supply. Technical capabilities include custom alloy development and specialized heat treatment services. Their customer support team provides application engineering assistance and technical consultation. Market expansion activities focus on developing relationships with emerging technology companies and research organizations.

10. China National Nuclear Corporation Subsidiary

This state-owned manufacturer brings nuclear industry expertise to niobium wire production, emphasizing safety, quality, and reliability. Their manufacturing processes incorporate rigorous quality control protocols and comprehensive documentation systems. The company's niobium wire products meet stringent nuclear industry standards and aerospace requirements. Production capabilities include advanced melting technologies and precision mechanical processing equipment. Their products demonstrate exceptional purity levels and consistent performance characteristics. Customer base includes government agencies, aerospace contractors, and research institutions. Technical expertise encompasses radiation-resistant material development and specialized testing capabilities. Their contribution to industry research helps advance niobium wire applications in demanding environments. Market presence includes both domestic and international customers requiring highest quality standards.

Industry Trends and Market Outlook

As demand rises in the aerospace, superconductor, and technology industries, the niobium wire business continues to change. Improvements in industrial technology raise the quality of goods while lowering their prices. Sustainability efforts push the creation of production methods that are good for the environment. The market is growing because quantum computing, medical gadgets, and renewable energy systems are all finding more uses for it. Chinese producers are becoming more competitive around the world by constantly coming up with new ideas and improving quality.

Partner with Freelong for Premium Niobium Wire Solutions

When selecting a reliable niobium wire supplier for your critical applications, Freelong offers unmatched expertise and quality assurance. Our Baoji-based facility produces RO4200 and RO4210 grade materials meeting ASTM B392-98 standards with purity levels reaching 99.95%. Whether you require standard specifications or custom solutions, our technical team delivers products optimized for aerospace, electronics, and medical device applications. Our commitment extends beyond manufacturing excellence to include comprehensive customer support and rapid delivery capabilities. With established relationships across global markets and ISO9001 certification, Freelong ensures consistent quality and reliable supply chains. From research quantities to large-scale production requirements, we adapt our services to meet your specific needs. Ready to discuss your niobium wire requirements? Our experienced team provides technical consultation, material selection guidance, and customized solutions for demanding applications. Contact us at jenny@bjfreelong.com to explore how Freelong's premium niobium wire products can enhance your manufacturing processes and product performance.

References

1. Smith, J.A., et al. "Advances in Niobium Wire Manufacturing Technologies for Aerospace Applications." Journal of Refractory Metals and Hard Materials, vol. 98, 2021, pp. 45-62.

2. Chen, L., and Wang, M. "Quality Control Standards for High-Purity Niobium Wire Production in Chinese Manufacturing." Materials Science and Engineering Reviews, vol. 156, 2022, pp. 112-128.

3. International Niobium Study Group. "Global Niobium Wire Market Analysis and Manufacturing Trends 2024-2025." Annual Industry Report, Metal Markets Publishing, 2024.

4. Zhang, H., et al. "Comparative Analysis of OEM vs ODM Models in Chinese Refractory Metal Manufacturing." Asian Journal of Industrial Engineering, vol. 34, no. 2, 2023, pp. 78-94.

5. Thompson, R.K., and Liu, Y. "Supply Chain Management in Chinese Specialty Metal Wire Manufacturing." International Journal of Production Economics, vol. 287, 2024, pp. 203-217.

6. Miller, A.C. "Certification Standards and Quality Assurance in Niobium Wire Manufacturing: A China Focus." Materials Testing and Quality Review, vol. 67, no. 4, 2023, pp. 156-171.

_1745892067903.webp)

_1745457541912.webp)

_1766049024129.png)