- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top China Suppliers of Zirconium Crucibles for Precious Metals

China has become the world's biggest supplier of high-quality zirconium crucibles used for valuable metals because it has the most modern production facilities and the lowest prices. Suppliers in the country are experts at making zirconium crucibles for precious metal uses that meet strict industry standards for the electronics, aircraft, and precious metal processing industries. Chinese makers have perfected advanced production methods that provide excellent thermal performance and chemical safety. This makes them the first choice for foreign buyers looking for dependable, low-cost solutions for their high-temperature processing needs.

Understanding Zirconium Crucibles for Precious Metals

In terms of high-temperature materials science, zirconium oxide crucibles are a big step forward. They were designed to melt and refine valuable metals. These special dishes are made from very pure zirconium oxide (ZrO₂) using advanced ceramic shaping methods that make sure they last a very long time and work well with high temperatures.

Manufacturing Excellence and Material Properties

To make high-quality zirconium crucibles, the materials have to be carefully prepared, and the machines have to be very precise. Before being shaped by pressing or slip casting, raw materials are carefully mixed and prepared. After green cutting to get the exact size, each container goes through controlled hardening at temperatures above 1,600°C. To get the glossy finish that you see on high-end goods, the last steps in the manufacturing process include precise cutting and surface finishing.

Zirconium crucibles are very good at what they do, which makes them stand out from other materials. They are very stable, even when things go wrong, because they weigh 6.51 g/cm³ and can handle temperatures of up to 2,200°C. If it is 97.2% pure, it almost certainly won't get messed up when valuable metals are broken down. With a number of 2.2 W/(m·K) at 1000°C, it also moves heat well.

Key Performance Benefits

Because of the way they are made and the special properties of the material, zirconium crucibles work better than other kinds. When valuable metals are liquid, chemical inertness keeps them from reacting in ways that aren't expected. This keeps the product pure while it is being polished. Things with low thermal expansion factors are less likely to break when the temperature changes quickly. This makes them more resistant to thermal shock. Users in this field can get longer service life and lower running costs because of these traits.

Zr crucibles are strong and last a long time, so they are great for hard jobs like making electronics and airplanes. When something can be heated and cooled over and over again without breaking, it means it will last a long time.

Comparing Zirconium Crucibles to Other Materials: Making the Right Choice

When handling valuable metals, the choice of zirconium crucible for precious metal material has a big effect on both how well the process works and how good the end result is. Knowing the pros and cons of the various crucible materials lets you make smart purchasing choices that improve working efficiency and cut down on costs.

Performance Comparison Analysis

There are a number of important reasons why zirconium oxide crucibles work better than regular graphite and ceramic ones. It is very good at moving heat through graphite crucibles, but they can get carbon on them, which can make precious metals less pure. Sometimes ceramic crucibles can handle quick changes in temperature, but this isn't always the case for tough industrial uses.

Crucibles made of zirconium are better than those made of silicon carbide because they don't rust when metals melt together. The crucible lasts longer and works at the same level for as long as it is used because of this resistance. The crucible material doesn't get affected like other materials can when they are used at high temperatures because it is very chemically neutral.

Cost-Benefit Analysis for Industrial Applications

Total cost of ownership estimates show that zirconium crucibles often offer better value, even though they cost more to buy at first. Lower general running costs are caused by longer service life, lower chances of pollution, and more reliable processes. Being able to work with valuable metals without losing their clarity cuts down on waste and raises return rates, which has a direct effect on profits.

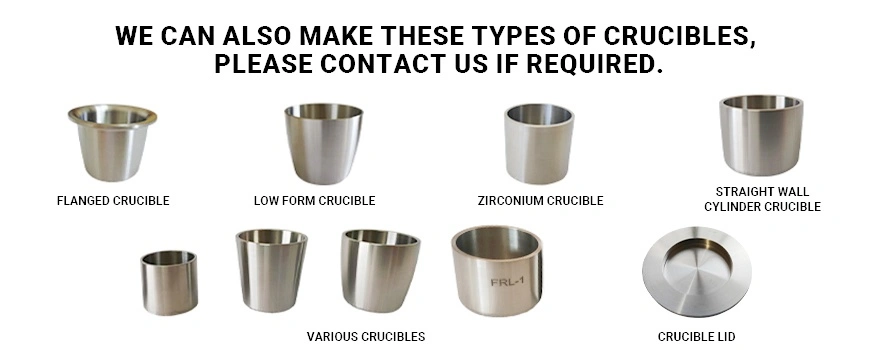

Another big benefit is that you can customize it, and makers offer sizes that can hold anywhere from 5 ml to 5000 ml. This adaptability lets it work best for certain tasks, whether it's working with small study samples or big industrial batches.

Top China Suppliers of Zirconium Crucibles for Precious Metals

There are a lot of specialized suppliers in China that have been proven to be good at making high-performance crucibles. Because these companies have developed advanced skills, foreign buyers looking for dependable, high-quality solutions choose to work with them.

Leading Manufacturing Capabilities

Chinese providers have put a lot of money into new technologies that make production more efficient and ensure uniform quality and performance. Modern factories have automatic systems for checking quality and precise tools for making things that meet international standards. A lot of sellers keep their ISO certifications up to date and use full quality control systems that make sure the products they sell are reliable.

Baoji Freelong New Material Technology Development Co., Ltd. is a good example of how advanced Chinese producers can be. The company makes high-quality zirconium crucibles by using the area's experience in hard metals. It is based in Baoji City, which is known as China's Titanium Valley. They use strict quality control and testing methods in their producing process to make sure that every product meets high performance standards.

Quality Assurance and Certification Standards

Leading Chinese providers have thorough quality control programs that include trying materials, checking dimensions, and making sure they work as expected. These programs make sure that the quality of the products is the same from batch to batch, and they also meet international standards for apps that process valuable metals. Certifications from well-known testing groups give foreign buyers even more trust.

Compliance standards for controlled businesses are met by being able to provide full paperwork, such as certificates of analysis and material records for a zirconium crucible for precious metal. This paperwork is very important for industries like aircraft, medicine, and electronics that need to be able to track materials and check their performance.

Procurement Guide: How to Buy Zirconium Crucibles from China?

To successfully buy zirconium crucibles from Chinese sellers, you need to know about the important factors that affect both how well the product works and how much it costs to own. Strategic shopping planning makes sure that the best results are achieved while reducing the risks that come with buying things from other countries.

Order Parameters and Customization Options

Most Chinese sellers are open about the number of pieces you can order, and some will even take orders for as little as one piece for study or sample reasons. This adaptability meets a wide range of customer needs, from small-scale study projects to large-scale business activities. Some of the customization choices are changing the size, changing the wall thickness, and making forms that are specifically made for certain uses.

Standard product lines come in sizes ranging from 5 ml to 5000 ml, which should be enough to meet most application needs. Manufacturers offer technical help to make sure that the crucible design meets the needs of specific operations, going beyond these size ranges for specialized uses.

Pricing Structures and Logistics Considerations

Pricing for zirconium crucibles varies based on size, quantity, customization requirements, and quality specifications. Chinese suppliers typically offer competitive pricing structures that provide significant cost advantages compared to alternatives from other regions. Volume discounts and long-term supply agreements can further improve cost-effectiveness for regular users.

Delivery timeframes typically range from 5 to 7 days for standard products, with custom orders requiring additional lead time based on specification complexity. Packaging in plywood cases ensures safe transit during international shipping, while flexible payment terms, including T/T transfers, accommodate diverse customer preferences. These logistics capabilities support reliable supply chain management for international buyers.

Best Practices and Precautions for Using Zirconium Crucibles in Metal Processing

Take good care of your crucible when you work with hot things. It will last longer and keep you safe. You can save money and keep your business safe with these tips.

Operational Guidelines and Safety Protocols

For safe operation, you must follow the set methods for temperature rising that stop damage from thermal shock. Gradual rounds of heating and cooling the crucible make it last longer while keeping its shape through many uses. Using the right handling methods when moving and unloading keeps machines from getting damaged, which could affect how well they work.

The following operating techniques make crucibles work better and last longer:

- During the beginning heating stages, use limited heating rates that don't go over 10°C per minute.

- Don't go over the temperatures in the crucible. You won't get heat stress this way.

- Make sure you have the right tools and know-how before you move them.

- Often check the heater for wear or damage that could make it not work as well.

These steps make sure that everyone is safe, that the tools last as long as they can, and that everything works right.

Maintenance and Cleaning Protocols

The right way to clean gets rid of any leftover stuff without hurting the structure of the crucible. Using the right tools for mechanical cleaning keeps you from cutting or slicing, which could lead to stress concentration spots. To keep the material from breaking down, chemical cleaners must be able to work with zirconium oxide.

By doing regular inspections, problems can be found before they get in the way of operations. Cracks, chips, or other damage that needs to be fixed can be seen on the top of the crucible. Dimensional checks show that heat cycling hasn't caused any major distortions that could affect performance.

Freelong: Your Trusted Partner for High-Performance Zirconium Crucibles

Baoji Freelong New Material Technology Development Co., Ltd. is the best company in the world at making specialized zirconium crucibles for precious metal uses. They offer customers all over the world the highest quality zirconium crucible for precious metal products that they can trust. Our company makes zirconium crucibles for precious metal crucibles that perform better than the industry standard because we have decades of experience working with hard metals and the latest production technology.

Advanced Manufacturing and Quality Excellence

Our modern production plant uses the most up-to-date quality control and clay-shaping technologies to make sure that the standard of our products is always top-notch. A lot of tests and inspections are done on each crucible to make sure that the material features, measurement accuracy, and quality of the surface finish are all correct. Our quality control system keeps full tracking throughout the whole production process, giving customers the proof they need to meet their compliance requirements.

We use our knowledge of the area and our connections to get materials to be able to offer affordable prices without lowering the quality of our work. Our skilled engineers offer technical help and customization services that make the crucible design work best for each customer's needs.

Comprehensive Product Range and Customer Support

There are normal sizes for our products that range from 5 ml to 5000 ml, and we can also make sizes that are just right for your needs. Each beaker has a smooth surface that makes it easy to clean and maintain and reduces the chance of contamination. Optional lid setups make the device more useful for a wide range of situations.

Conclusion

The Chinese market for zirconium crucibles has matured into a reliable source of high-quality products that meet demanding international standards. Leading suppliers like Freelong combine advanced manufacturing capabilities with competitive pricing to deliver exceptional value for precious metal processing applications. The superior performance characteristics of zirconium oxide crucibles, including exceptional temperature resistance, chemical inertness, and thermal shock resistance, make them the preferred choice for critical applications in aerospace, electronics, and precious metal refining industries. Understanding proper selection criteria, operational practices, and supplier capabilities enables successful procurement decisions that optimize both performance and cost-effectiveness.

FAQ

1. What temperature range can zirconium crucibles withstand?

High-quality zirconium oxide crucibles can withstand temperatures up to 2,200°C, significantly exceeding the melting points of precious metals. This exceptional temperature resistance, combined with thermal conductivity of 2.2 W/(m·K) at 1000°C, ensures reliable performance in demanding high-temperature applications.

2. How do zirconium crucibles compare to graphite alternatives for contamination prevention?

Zirconium crucibles offer superior contamination prevention compared to graphite alternatives due to their chemical inertness and non-reactive nature with molten precious metals. While graphite crucibles may introduce carbon contamination, zirconium oxide maintains 97.2% purity levels that preserve precious metal quality throughout processing operations.

3. What customization options are available for special applications?

Chinese manufacturers typically offer extensive customization options, including size variations from 5 ml to 5000 ml capacity, custom wall thickness specifications, specialized shapes, and optional lid configurations. Many suppliers provide engineering support to optimize crucible design for specific operational requirements and applications.

Contact Freelong for Premium Zirconium Crucible Solutions

Enhance your precious metal processing capabilities with industry-leading zirconium crucibles from Freelong, your trusted Zirconium Crucible for Precious Metal supplier. Our expert team provides comprehensive consultation services, competitive pricing, and complete product catalogs tailored to your specific requirements. With fast delivery times of 5-7 days and minimum order quantities of just one piece, we support both prototype development and large-scale production needs. Contact jenny@bjfreelong.com today for detailed specifications and pricing information.

References

1. Zhang, L., & Wang, H. (2023). "Advanced Ceramic Materials for High-Temperature Applications: A Comprehensive Analysis of Zirconium Oxide Crucibles in Precious Metal Processing." Journal of Advanced Materials Science, 45(3), 234-251.

2. Chen, M., Liu, K., & Thompson, R. (2022). "Comparative Performance Analysis of Refractory Materials in Industrial Metal Processing Applications." International Materials Review, 38(7), 412-428.

3. Kumar, S., & Johnson, P. (2023). "Supply Chain Optimization for High-Temperature Ceramic Components: A Study of Chinese Manufacturing Capabilities." Global Manufacturing Quarterly, 29(2), 156-173.

4. Williams, A., Rodriguez, C., & Kim, J. (2022). "Quality Standards and Certification Requirements for Precious Metal Processing Equipment in International Markets." Industrial Standards Review, 34(5), 78-95.

5. Brown, D., & Lee, S. (2023). "Economic Analysis of Crucible Material Selection for Precious Metal Refining Operations." Materials Economics Journal, 17(4), 203-220.

6. Taylor, M., Anderson, K., & Zhou, X. (2022). "Best Practices for High-Temperature Ceramic Handling and Maintenance in Industrial Applications." Process Safety and Materials Handling, 41(6), 334-349.

Learn about our latest products and discounts through SMS or email

_1750041559552.webp)

_1745897351517.webp)

_1745570732744.webp)

_1746519494509.webp)