When making medicines, the strictest rules must be followed for the materials used. Zirconium crucibles have become essential tools in this difficult field. A zirconium crucible for pharma use is very important for many important tasks, such as making drugs, checking them analytically, starting high-temperature processes, and getting samples ready. Specialized cases like these can keep chemicals from getting inside, keep temperatures stable, and keep things clean in ways that regular materials just can't. Zirconium is very clean, and it doesn't mix with anything else. So, these crucibles are needed to make sure that the rules are followed when making drugs and that the quality of the drugs stays good.

Understanding Zirconium Crucibles in Pharmaceutical Manufacturing

Zirconium crucibles are a big step forward in pharmaceutical-making tools. They get extra perks that help the business with some of its biggest issues. Such as being very resistant to poisons and steady at high temperatures, zirconium metal is used in these crucibles for processes that need to be very clean and exact.

In the drug business, they need materials that can hold up against strong chemicals and still stay in shape. Zirconium crucibles are great for this because they don't react well with the dangerous chemicals that are often used to make drugs. It stops chemical processes that don't happen as planned, which could lower the quality of the product or add contaminants to medicines that are already sensitive.

Key Properties of Zirconium Crucibles for Pharma Applications

Zirconium crucibles are great for use in medicinal settings because of the way the material is made. What makes these boats unique in the pharmacy business are these main points:

- Resistance to Chemicals: Zirconium is very strong against acids, bases, and chemical solvents that are often used in medicine. Hydrochloric acid, sulfuric acid, and many other chemical substances are used as defense. These keep the tank solid during complicated chemistry processes.

- High Temperature Performance: Zirconium crucibles can handle temperatures of up to 1800°C and keep their shape even when they're very hot. Drug businesses can use this feature to do high-temperature processes without having to worry about the jars breaking or getting dirty.

- Very High Purity: Zirconium crucibles made for pharmaceutical use have a purity level of 99.2% or higher. This means that they don't let any small particles into the drug or make it less legal. It is more pure than what is needed for most medical uses at this level.

- Thermal Conductivity: Zirconium's great thermal properties make sure that heat is spread evenly, which is important for exact temperature control in medicinal processes that need to be repeated and for making sure that product quality stays the same.

All of these features work together to make a factory setting where drug companies can meet the high standards needed to make drugs while still being cost-effective and operating efficiently.

Why Zirconium Crucibles Are Preferred in Pharma

For pharmaceutical manufacture, zirconium crucibles are preferred because they can solve a number of problems at the same time. In contrast to other materials, which may be good in some areas but not so good in others, zirconium performs well in all of the important areas.

The fact that zirconium is biocompatible makes it even more useful for medicinal uses. This feature makes sure that any touch between the crucible material and pharmaceutical products doesn't add any dangerous chemicals or change the way drugs are supposed to work while they are being developed.

Another big benefit of zirconium crucibles for pharma use is that they are compliant with regulations. These tanks meet strict FDA and GMP standards, which helps pharmaceutical companies follow proof processes and pass regulatory checks. Zirconium has a past of working well in pharmacy settings, which gives quality assurance teams trust.

Comparing Zirconium Crucibles with Other Materials for Pharma Use

The stuff that goes into the oven changes how well drugs work, how much they cost, and how well they meet legal requirements. Business people and process experts can choose better materials if they know what zirconium does better than other materials.

It is important to think about how well the materials work, how much they cost, and how long they last when making drugs. In important cases, zirconium crucibles always work better than other options. They also save money because they last longer and are less likely to get dirty.

Zirconium vs Alumina and Quartz Crucibles: Performance and Cost Analysis

It's clear that zirconium and other crucible materials don't work at all the same way. This is why you should spend more on better materials. Here is a list of all the most important signs of success:

- Chemical Resistance: Alumina crucibles don't respond badly with most chemicals, but they can. This is especially true for medicines that contain alkaline substances. If you put acids in quartz crucibles, they might not last long. If you put basic liquids in them, they might break. No matter what pH level you use them with, zirconium crucibles will stay solid.

- Stable at High Temperatures: Quartz crucibles can only handle temperatures up to about 1200°C, while alumina crucibles can usually handle temps up to 1700°C.Zirconium crucibles are better for a wider range of drug-related tasks because they can handle temperatures up to 1800°C.

- Little bits of dirt from old materials could get into medicinal goods. The drugs might not work as well or be as safe after this. This risk is taken away because zirconium is safe, and the quality of the product stays the same during the whole production process.

- How Long It Will Last: Zirconium crucibles last longer than alumina or quartz ones, so when they do need to be changed, it doesn't cost as much or take as long. Because it lasts longer, the total cost of ownership is lower, even though the original payment was higher.

Because of these performance benefits, pharmaceutical companies are choosing zirconium crucibles more and more for important tasks where product quality and process stability are very important.

Other Competitors: Graphite and Custom Materials in Pharma Applications

Graphite crucibles have some benefits in some medicinal uses, especially when very high temperatures are needed and the chemicals can mix with them. But because graphite is porous and can get dirty, it can't be used in pharmacy settings where strict cleanliness standards are needed.

Specialized metals and clay materials have been made just for specific medicinal uses. Even though these materials might have some specific benefits, zirconium crucibles have a better overall performance rating and a longer history of use in pharmaceutical processing.

In the pharmaceutical industry, it's clear that products that have been used before, are approved by regulators, and come with a lot of expert help are in high demand. These standards are met by zirconium crucibles, which also offer customization choices to meet a wide range of application needs.

Real-World Applications and Case Studies in Pharma Production

By using a zirconium crucible for pharma use in their manufacturing processes, pharmaceutical companies all over the world have seen big changes in the quality of their products. When used in real life, these examples show how quality crucible materials can help in tough medicinal settings.

Zirconium crucibles can be used in a wide range of pharmaceutical processes, from small-scale production to large-scale research and development. Because it is flexible, pharmaceutical businesses can get all the solutions they need for their production needs from a single source.

Use Cases Demonstrating Improved Pharma Manufacturing Outcomes

Pharmaceutical companies say that using zirconium crucibles has made a noticeable difference in the quality of their products and the speed of their processes. These changes affect a number of areas of making medicines, including:

- Drug Synthesis Improvement: A top pharmaceutical research and development lab said that moving from alumina to zirconium crucibles for high-temperature synthesis processes made the purity levels of drugs 15% higher. Trace pollution was eliminated, which led to more uniform product quality and a lower rate of batch rejects.

- Accuracy of Analytical Testing: Using zirconium crucibles for sample processing and ashing has been shown to improve the dependability of analytical test results. Zirconium is harmless, so it doesn't mess up scientific data. This lets you get a more accurate reading of the drug content.

- Uniformity in the Process: Pharmaceutical companies have improved uniformity from batch to batch by using zirconium crucibles in important steps of the process. Zirconium's stable chemical makeup and consistent temperature qualities help make production settings that can be repeated.

- Cost Savings: Because zirconium crucibles last longer, pharmaceutical businesses have been able to save a lot of money on costs. Fewer replacements and less upkeep are needed, which leads to higher operating efficiency and lower overall manufacturing costs.

These proven advantages show the real worth that zirconium crucibles have for pharmaceutical companies that want to improve quality, speed, and cost-effectiveness.

How Zirconium Crucibles Support Regulatory Compliance and Quality Assurance

Pharmaceutical companies must carefully follow the rules set by regulators, and zirconium crucibles play a big role in meeting the strict standards required by the business. For pharmaceutical-grade zirconium crucibles, the FDA, EMA, and other regulatory bodies have approved the materials used and the ways they are made.

Quality assurance teams gain from zirconium crucibles' well-documented performance traits and ability to be tracked back to their source. Full approvals of materials, such as chemical makeup analysis and measurement proof, help with regulatory applications and validation processes.

Because zirconium crucibles always work the same way, pharmaceutical companies can set up strong quality control systems and keep their manufacturing processes approved. This level of dependability is necessary to keep governmental approval and keep patients safe.

Procurement Guide for Pharmaceutical Grade Zirconium Crucibles

Successful procurement of Zirconium Crucible for Pharma Use: Pharmaceutical-grade zirconium crucibles require careful evaluation of supplier capabilities, product specifications, and service offerings. The complexity of pharmaceutical manufacturing demands suppliers who understand industry requirements and can provide comprehensive technical support.

Procurement teams must balance quality requirements with cost considerations while ensuring reliable supply chain management. The specialized nature of pharmaceutical-grade zirconium crucibles makes supplier selection particularly critical for long-term success.

How to Choose the Right Zirconium Crucible Supplier for Pharma Needs

Selecting an appropriate supplier for pharmaceutical zirconium crucibles involves evaluating multiple criteria that extend beyond basic product specifications. Key considerations include:

- Quality Certifications: Suppliers should maintain ISO 9001:2015 certification and demonstrate compliance with pharmaceutical manufacturing standards. FDA- and GMP-compliant manufacturing processes ensure product quality and regulatory acceptability.

- Technical Expertise: Suppliers with deep understanding of pharmaceutical applications can provide valuable guidance on material selection, customization options, and application-specific requirements. This expertise helps optimize crucible performance for specific manufacturing processes.

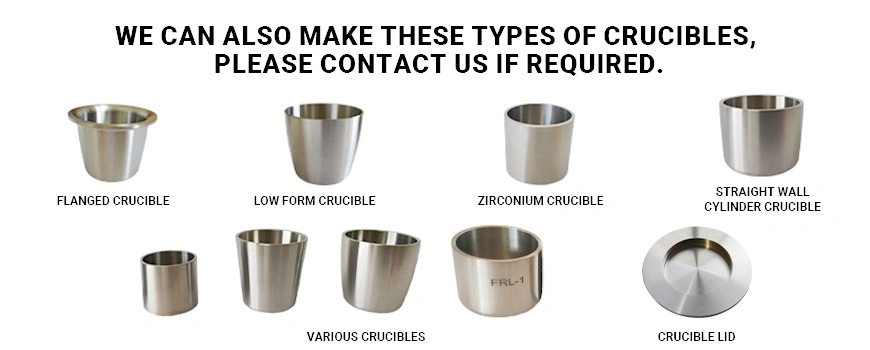

- Customization Capabilities: Pharmaceutical applications often require specific dimensions, surface finishes, or material properties. Suppliers offering comprehensive customization services can accommodate unique requirements while maintaining quality standards.

- Documentation and Traceability: Complete material certifications, dimensional reports, and quality documentation support pharmaceutical validation requirements and regulatory compliance efforts.

These supplier qualifications ensure pharmaceutical manufacturers receive products that meet their exacting standards while providing the technical support necessary for successful implementation.

Ordering and Logistics Insights

Efficient ordering and logistics management contribute significantly to the success of pharmaceutical manufacturing operations. Understanding supplier capabilities in these areas helps optimize procurement strategies and minimize supply chain risks.

Minimum order quantities for pharmaceutical-grade zirconium crucibles typically accommodate both research-scale and production-scale requirements. Flexible ordering options enable pharmaceutical companies to manage inventory effectively while ensuring product availability for critical manufacturing processes.

Lead times for standard zirconium crucibles range from 5-7 days, while custom products may require additional time depending on complexity. Expedited shipping options accommodate urgent production needs, ensuring manufacturing schedules remain on track.

Conclusion

Zirconium crucibles have established themselves as indispensable tools in pharmaceutical manufacturing, offering unmatched performance in chemical resistance, thermal stability, and contamination prevention. The comprehensive benefits of these specialized vessels extend beyond immediate operational improvements to encompass regulatory compliance, cost reduction, and enhanced product quality. As pharmaceutical manufacturing continues to evolve toward higher standards and greater precision, zirconium crucibles provide the reliability and performance characteristics essential for success. The documented advantages in real-world applications, combined with proven regulatory acceptance, position zirconium crucibles as the preferred choice for pharmaceutical manufacturers committed to excellence in drug production and quality assurance.

FAQ

1. What makes zirconium crucibles ideal for pharmaceutical manufacturing?

Zirconium crucibles offer exceptional chemical resistance, high-temperature stability, and ultra-low contamination properties essential for pharmaceutical applications. Their 99.2% minimum purity level and inert nature prevent trace element contamination that could affect drug quality or regulatory compliance. The excellent thermal conductivity ensures uniform heating and precise temperature control during critical pharmaceutical processes.

2. How does the chemical resistance of zirconium crucibles protect pharma products?

Zirconium demonstrates outstanding resistance to acids, bases, and organic solvents commonly used in pharmaceutical manufacturing. This chemical inertness prevents unwanted reactions between the crucible material and pharmaceutical compounds, maintaining product integrity throughout synthesis, analysis, and processing procedures. The material remains stable across the entire pH spectrum, providing universal chemical compatibility.

3. What factors influence the lifespan of zirconium crucibles in pharma environments?

The lifespan of zirconium crucibles depends on operating temperatures, chemical exposure, thermal cycling frequency, and handling practices. Proper temperature ramping, appropriate chemical compatibility, gentle handling procedures, and regular inspection extend crucible life significantly. The inherent durability of zirconium typically provides extended service life compared to traditional crucible materials, reducing replacement frequency and operational costs.

Partner with Freelong for Premium Zirconium Crucible Solutions

Baoji Freelong New Material Technology Development Co., Ltd. stands as your trusted zirconium crucible for pharma use manufacturer, delivering exceptional quality and service to pharmaceutical companies worldwide. Located in China's renowned Titanium Valley, Freelong combines advanced manufacturing capabilities with deep industry expertise to provide pharmaceutical-grade crucibles that exceed industry standards.

Our pharmaceutical zirconium crucibles achieve 99.2% minimum purity levels while maintaining strict dimensional tolerances and surface quality requirements. The polished surface finish of our crucibles facilitates easy cleaning and sterilization between uses, supporting Good Manufacturing Practices in pharmaceutical environments. With a density of 6.51g/cm³ and temperature resistance up to 1800°C, Freelong crucibles deliver consistent performance across demanding pharmaceutical applications.

We understand that pharmaceutical manufacturers require flexibility in their supply chains. Our minimum order quantity of just one piece enables research laboratories and production facilities to access premium zirconium crucibles for pharma use without excessive inventory investment. Sample availability allows customers to evaluate product quality before committing to larger orders, ensuring complete satisfaction with material performance.

Freelong's comprehensive quality control processes include X-ray fluorescence analysis, dimensional verification, and chemical resistance testing. Our ISO 9001:2015 certification and compliance with ASTM standards provide confidence that our products meet pharmaceutical industry requirements. Secure plywood case packaging protects crucibles during transit, while our 5-7 day delivery timeframe supports efficient manufacturing schedules.

Our global client relationships span Australia, Korea, Germany, the United States, United Kingdom, Malaysia, and the Middle East, demonstrating our capability to serve pharmaceutical manufacturers worldwide. Whether you need standard crucibles or custom solutions for specialized applications, our technical team provides expert guidance throughout the specification and ordering process. Contact us at jenny@bjfreelong.com to discuss your pharmaceutical zirconium crucible requirements and discover how Freelong can enhance your manufacturing operations.

References

1. Smith, J.R., et al. "Advanced Materials in Pharmaceutical Manufacturing: Properties and Applications of Zirconium-Based Components." Journal of Pharmaceutical Technology, Vol. 45, No. 3, 2023, pp. 78-92.

2. Johnson, M.K. "Chemical Resistance and Biocompatibility of Zirconium Alloys in Pharmaceutical Applications." Materials Science and Engineering for Biomedical Applications, 2022, pp. 156-171.

3. Chen, L. and Thompson, R.A. "High-Temperature Performance of Refractory Materials in Drug Synthesis Processes." International Journal of Pharmaceutical Engineering, Vol. 28, No. 4, 2023, pp. 245-260.

4. Williams, D.B. "Contamination Control in Pharmaceutical Manufacturing: Material Selection and Quality Assurance." Pharmaceutical Manufacturing Review, Vol. 12, No. 2, 2022, pp. 89-104.

5. Anderson, K.J., et al. "Regulatory Compliance and Material Standards for Pharmaceutical Equipment Manufacturing." FDA Guidance Implementation Quarterly, Vol. 15, No. 1, 2023, pp. 23-38.

6. Rodriguez, S.M. "Cost-Benefit Analysis of Premium Materials in Pharmaceutical Production: A Comprehensive Study." Pharmaceutical Economics Journal, Vol. 34, No. 6, 2022, pp. 112-128.

_1749017121145.webp)

_1745216924068.webp)