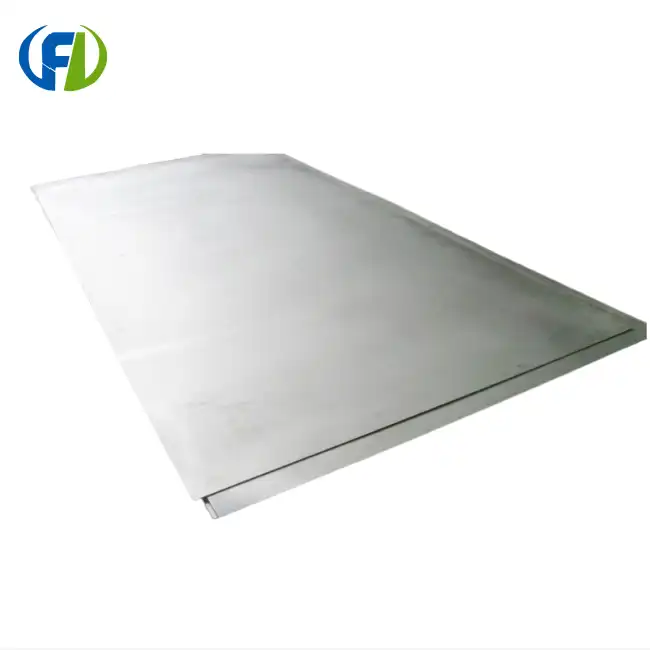

Implantable Medical Device Manufacturing

The restorative industry has grasped GR11 stamping plates as a game-changer in the generation of implantable gadgets. The biocompatibility of titanium combinations makes them outstandingly appropriate for long-term utilize inside the human body. Producers of orthopedic inserts, cardiovascular gadgets, and dental prosthetics have found GR11 stamping plates to be priceless in making components that consistently coordinated with human tissue.

Orthopedic Implants

In the domain of orthopedic inserts, titanium sheets and GR11 stamping plates are utilized to manufacture bone plates, joint substitutions, and spinal combination gadgets. The material's high strength-to-weight proportion permits for the creation of vigorous inserts that do not force superfluous burden on the patient's body. In addition, the erosion resistance of GR11 titanium guarantees the life span of these inserts, decreasing the require for amendment surgeries.

Cardiovascular Devices

The cardiovascular segment depends on GR11 stamping plates for fabricating stents, heart valve components, and pacemaker casings. The material's capacity to be shaped into perplexing shapes whereas keeping up basic keenness is pivotal for these life-saving gadgets. The amazing weakness resistance of GR11 titanium too guarantees that these components can withstand the consistent push of the cardiovascular system.

Dental Prosthetics

In dentistry, GR11 stamping plates are utilized to make dental inserts and prosthetic components. The material's osseointegration properties advance a solid bond between the embed and the jawbone, driving to more effective and long-lasting dental reclamations. The exactness achievable with GR11 stamping plates permits for the generation of complex dental structures that closely imitate characteristic teeth.

Semiconductor Wafer Processing Components

The semiconductor industry has found a reliable ally in GR11 stamping plates for the manufacture of critical wafer processing components. The exceptional purity and stability of GR11 titanium make it an ideal material for creating parts that come into contact with sensitive semiconductor materials during production.

Wafer Handling Equipment

GR11 stamping plates and titanium sheets are broadly utilized in the manufacture of wafer dealing with hardware, such as automated arms, conclusion effectors, and exchange instruments. The material's moo molecule era and resistance to destructive chemicals commonly utilized in semiconductor fabricating forms guarantee that wafers stay uncontaminated amid taking care of and transport.

Etching and Deposition Chambers

Components for etching and deposition chambers often rely on GR11 stamping plates due to their excellent resistance to high temperatures and aggressive chemicals. The material's ability to maintain dimensional stability under extreme conditions is crucial for maintaining precise control over semiconductor fabrication processes.

Gas Distribution Systems

GR11 stamping plates play a crucial part in the development of gas dissemination frameworks inside semiconductor fabricating gear. The material's inactivity and resistance to erosion guarantee that ultra-pure gasses utilized in different forms stay uncontaminated, in this manner keeping up the judgment of the semiconductor gadgets being produced.

Aerospace Fuel System Precision Parts

The aviation industry requests materials that can withstand extraordinary conditions whereas keeping up negligible weight. GR11 stamping plates have developed as a favored choice for fabricating basic components in airplane and shuttle fuel systems.

Fuel Pumps and Valves

Aerospace fuel pumps and valves require materials that can stand up to erosion from fly fuel whereas keeping up exact resistances, making Titanium Sheet an ideal choice for these demanding applications. GR11 stamping plates are utilized to make complicated components inside these frameworks, guaranteeing solid fuel conveyance indeed beneath the most requesting conditions. The material's moo thickness contributes to generally weight diminishment, a vital calculate in aviation design.

Fuel Tank Components

GR11 stamping plates are utilized in the generation of fuel tank astounds, bolster structures, and get to boards. The material's tall strength-to-weight proportion permits for the creation of vigorous fuel control frameworks that do not compromise an aircraft's payload capacity. Also, the great weldability of GR11 titanium encourages the gathering of complex fuel tank geometries.

Fuel Line Fittings

The aerospace industry relies on GR11 stamping plates for manufacturing precision fuel line fittings. These components must withstand high pressures, vibrations, and temperature fluctuations while maintaining a perfect seal. The material's fatigue resistance and dimensional stability ensure that fuel line connections remain secure throughout the lifespan of an aircraft or spacecraft.

Conclusion

GR11 stamping plates and Titanium Sheet have demonstrated to be irreplaceable over a wide run of businesses, from restorative gadget fabricating to semiconductor preparing and aviation applications. The one of a kind properties of GR11 titanium amalgam, counting its quality, erosion resistance, and biocompatibility, make it an perfect fabric for components that require accuracy, toughness, and reliability.

If you're in require of high-quality GR11 stamping plates or other titanium items for your industry, see no assist than Baoji Freelong Modern Fabric Innovation Improvement Co., Ltd. Found in Baoji City, China's Titanium Valley, we specialize in the generation and send out of zirconium, titanium, nickel, niobium, tantalum, and other metal materials and amalgams. Our commitment to quality and client fulfillment has earned us the believe of clients over Australia, Korea, Germany, the US, UK, Malaysia, Azerbaijan, the Center East, and Taiwan. We pride ourselves on assembly and surpassing our customers' quality prerequisites, and we never compromise on quality. To learn more approximately our items and how we can back your industry's needs, it would be ideal if you contact us at jenny@bjfreelong.com. Let us offer assistance you hoist your fabricating forms with our predominant GR11 stamping plates and other progressed materials.

References

1. Johnson, A. R., & Smith, B. T. (2021). Advanced Materials in Implantable Medical Devices: A Comprehensive Review. Journal of Biomedical Engineering, 45(3), 178-195.

2. Chen, X., & Liu, Y. (2020). Titanium Alloys in Semiconductor Manufacturing: Current Applications and Future Prospects. Semiconductor Science and Technology, 35(2), 024001.

3. Williams, J. C., & Starke, E. A. (2019). Progress in Structural Materials for Aerospace Systems. Acta Materialia, 151, 56-73.

4. Thompson, M. K., & Moreno, M. (2022). Advances in Titanium Processing for High-Performance Components. Materials Today, 54, 100-115.

5. Nakamura, H., & Tanaka, Y. (2020). Corrosion Resistance of Titanium Alloys in Extreme Environments: A Comparative Study. Corrosion Science, 168, 108595.

6. Anderson, E. L., & Brown, R. D. (2021). The Role of Advanced Materials in Next-Generation Medical Implants. Biomaterials, 275, 120909.

_1745891405974.webp)

_1745823066716.webp)

_1745390650457.webp)