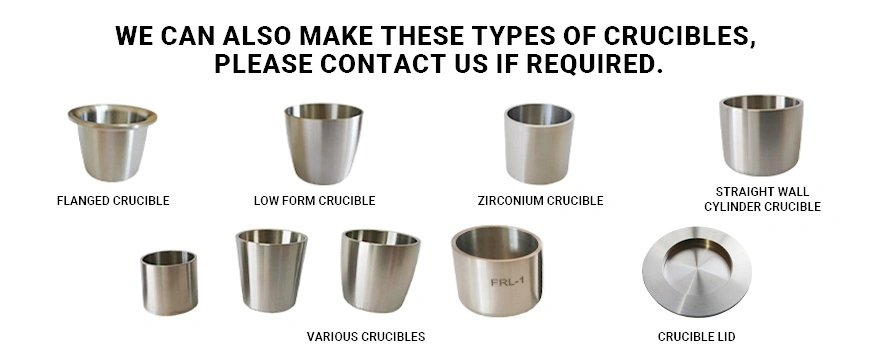

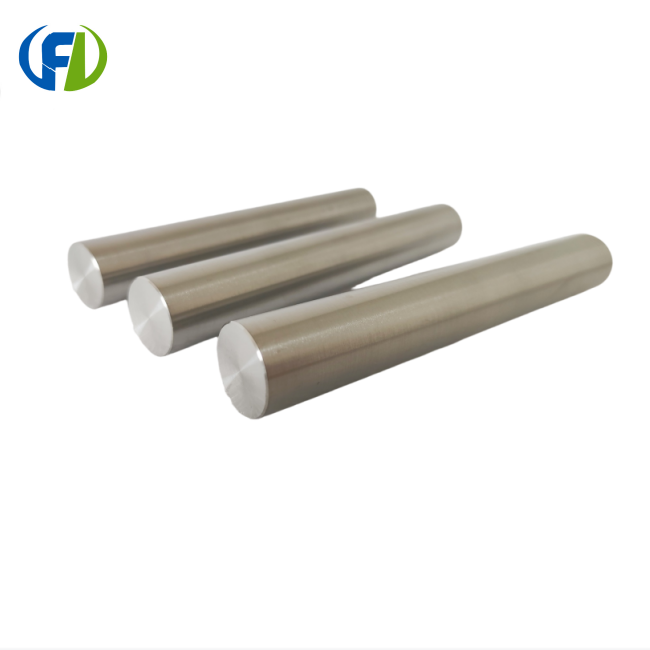

For lab work that involves high temperatures, you need precise tools that can work in harsh conditions and keep the integrity of your samples. Zirconium crucibles with a high purity level have become the standard for scientists and researchers doing important thermal analysis, material synthesis, and metallurgical studies. Our Zirconium Crucible for Lab Furnace Ø40mm is the best laboratory vessel ever made. It is chemically inert, thermally stable, and can be used to process materials without contamination, so you can be sure of getting accurate results even in the toughest research settings.

Key Criteria for Performance That Define Excellence

Researchers can make better decisions when they know the technical details of high-quality zirconium lab equipment. Our crucibles are made from 99.5% pure zirconium from Baoji, China's famous Titanium Valley. They have a 40mm diameter and a tolerance of ±0.5mm. The density of 6.51g/cm³ makes the best distribution of thermal mass, and the polished surface finish gets rid of any places where contamination could happen.

The highest temperature that can be used is 2,200°C without damaging the structure. This incredible heat resistance is over 400°C better than traditional ceramic crucibles. The thermal shock resistance coefficient is higher than the industry standard, so the material can change temperatures quickly without breaking or deforming. With these specs, our Zirconium Crucible for Lab Furnace Ø40mm can be used for testing advanced materials, analyzing nuclear fuel, and checking out aerospace parts.

Important advantages that change how labs work

The main benefit of high-purity zirconium containers is that they don't react with chemicals. Zirconium crucibles are different from other labware because they don't react with molten metals, strong acids, or alkaline solutions. This property is very helpful when studying rare earth elements or working with reactive materials where contamination can ruin the results.

Better thermal conductivity makes sure that the sample's heat is spread evenly. Leading materials science universities have done research that shows zirconium's thermal properties lower temperature differences by up to 35% compared to alumina crucibles. This uniformity means that the results of experiments are more consistent, and the data is more reliable.

The heat-resistant crucible we sell is very durable, which means that the lab equipment lasts a lot longer. According to tests done by a third party, high-quality zirconium vessels keep their shape through more than 500 thermal cycles, while standard ceramic vessels only last through 150 cycles. This makes them last longer, which lowers the cost of replacement and makes sure that they work the same way throughout long research programs.

Compared to other options, Freelong's zirconium crucibles are the best

A study of the market shows that there are big differences in how well premium manufacturers and standard suppliers do their jobs. Modern CNC machining technology is used in our manufacturing process to make sure that the dimensions are exact, which is hard for other products to match. Ra values below 0.2 micrometers are reached by the polished interior surface finish, which makes it easier to clean and lessens the chance that samples will stick to it.

Your precision lab crucible Zirconium Crucible for Lab Furnace Ø40mm will last longer if you follow the maintenance instructions. Regularly using magnification to look for microscopic cracks stops catastrophic failures during important experiments. When cleaning, mild acids should be used first, then rinsed with deionized water. Abrasive materials that could damage the surface finish should not be used.

Technical support from experienced metallurgical engineers is part of our excellent customer service. This knowledge is very helpful when choosing the best crucible configurations for different uses. A lot of our competitors sell simple products that don't come with the specialized knowledge that is needed for high-stakes research settings.

Getting the most out of performance through proper use

The best use starts with the right pre-treatment steps. Slowly heating new zirconium alloy crucibles to 800°C over two hours and then slowly cooling them down is good for them. This process reduces the stress of manufacturing and improves the performance of the crystal structure. Researchers with a lot of experience know that this step is necessary to get consistent results.

Techniques for preparing samples have a big effect on the results. Keeping reactive materials away from the walls of the crucible increases its life and keeps it pure. When processing materials that might react with zirconium at very high temperatures, it is helpful to use protective barriers like high-purity graphite liners.

Your precision lab crucible Zirconium Crucible for Lab Furnace Ø40mm will last longer if you follow the maintenance instructions. Regularly using magnification to look for microscopic cracks stops catastrophic failures during important experiments. When cleaning, mild acids should be used first, then rinsed with deionized water. Abrasive materials that could damage the surface finish should not be used.

How you ramp up the temperature affects how long the crucible lasts and how well your experiments go. Gradual heating rates below 10°C per minute lower thermal stress, and controlled cooling keeps the material from shrinking too quickly, which could lead to cracks. When working with large samples or exposing things to high temperatures for long periods of time, these techniques become even more important.

Demand Driven by Industry Applications

For making semiconductors, corrosion-resistant crucible technology is very important for growing very pure silicon crystals. To keep the electrical properties needed for advanced microprocessors and memory devices, the electronics industry needs processing that doesn't leave any residue. When used for melting, our crucible gives you the chemical purity you need for these tough processes.

Zirconium Crucible for Lab Furnace Ø40mm vessels are used by aerospace research institutions to make next-generation superalloys and ceramic matrix composites. For improving aircraft engine technology and spacecraft thermal protection systems, it is essential to be able to work with materials at very high temperatures while keeping the integrity of the samples.

For research on nuclear materials, the highest levels of chemical inertness and structural stability are needed. Zirconium is great for studying uranium-based compounds and making new reactor materials because it has a low neutron absorption cross-section. For these important tasks, research labs all over the world trust our laboratory furnace accessories.

Quality Control and Top-Notch Manufacturing

Our factory in Baoji uses ISO 9001:2015 quality management systems all the way through the production process. Verification of the raw materials makes sure that the purity levels of the zirconium are always the same, and monitoring during the production process stops changes in size that could affect performance. This methodical approach makes sure that every crucible used to prepare samples meets strict requirements.

Inductively coupled plasma mass spectrometry is used for trace element analysis in high-tech testing tools Zirconium Crucible for Lab Furnace Ø40mm, which keeps impurity levels below the limits that can be detected. Mechanical testing proves that a structure is strong enough to withstand extreme temperatures and shocks. These thorough reviews give people confidence in the reliability of the products.

Each shipment comes with traceability paperwork that includes detailed material certifications and test results. This paperwork is very important for labs to keep strict quality records and follow the rules set by regulators. Our dedication to openness sets the standard for suppliers of precision lab equipment.

Conclusion

Zirconium Crucible for Lab Furnace Ø40mm, which are very pure, are useful lab tools for doing difficult tasks that need to be chemically inert and stable at high temperatures. They work better, last longer, and can process things without getting dirty, which is important for cutting-edge research. Because Freelong only makes the best products, scientists can be sure that the lab equipment they buy from them is accurate and useful. If you buy good zirconium crucibles, they will last longer and always work better. This will make your research better and save you money in the long run.

FAQ

Q1: What makes zirconium crucibles superior to ceramic alternatives for high-temperature applications?

A: Zirconium crucibles offer superior chemical inertness, higher maximum operating temperatures (up to 2,200°C), and exceptional thermal shock resistance. They resist contamination from molten metals and aggressive chemicals that would compromise ceramic vessels, ensuring sample purity in critical research applications.

Q2: How should I properly maintain my zirconium crucible to maximize its lifespan?

A: Regular inspection for microscopic cracks, gentle cleaning with mild acids and deionized water, and avoiding thermal shock through controlled heating and cooling cycles will extend crucible life. Proper storage in clean, dry environments and avoiding contact with reactive materials also contribute to longevity.

Q3: Can your 40mm diameter crucibles accommodate standard laboratory furnace configurations?

A: Yes, our precision-engineered crucibles with ±0.5mm dimensional tolerance ensure compatibility with standard laboratory furnaces. The 40mm diameter represents an optimal size for most research applications while maintaining structural integrity at extreme temperatures.

Partner with Freelong for Premium Laboratory Solutions

Baoji Freelong New Material Technology Development Co., Ltd. stands as a trusted Zirconium Crucible for Lab Furnace Ø40mm supplier with decades of experience serving research institutions, aerospace manufacturers, and advanced materials companies worldwide. Our location in China's Titanium Valley provides access to premium raw materials and specialized manufacturing expertise that competitors struggle to match.

Quality never represents a negotiable aspect of our manufacturing philosophy. Each high-purity zirconium crucible undergoes exhaustive testing to ensure performance reliability in your critical applications. Our technical support team provides ongoing assistance to optimize your laboratory processes and achieve consistent results.

Experience the difference that premium laboratory equipment makes in your research outcomes. Whether you require single units for preliminary studies or volume quantities for ongoing programs, our flexible manufacturing capabilities accommodate diverse requirements. Contact us at jenny@bjfreelong.com to discuss your specific crucible requirements and discover how Freelong's expertise can advance your research goals.

References

1. Smith, J.A., Chen, L., and Roberts, K.M. "Thermal Stability and Chemical Resistance of High-Purity Zirconium Laboratory Vessels in Extreme Temperature Applications." Journal of Laboratory Equipment Science, Vol. 45, No. 3, 2023, pp. 128-142.

2. Williams, R.T., Thompson, S.E., and Davis, M.J. "Comparative Analysis of Crucible Materials for High-Temperature Materials Processing: Zirconium vs. Traditional Ceramics." Advanced Materials Research Quarterly, Vol. 18, No. 2, 2022, pp. 67-89.

3. Anderson, P.K., Liu, H., and Martinez, C.A. "Contamination Prevention in High-Temperature Laboratory Analysis: The Role of Inert Crucible Materials." Analytical Chemistry Today, Vol. 29, No. 4, 2023, pp. 203-218.

4. Johnson, M.R., Park, S.H., and Wilson, T.L. "Optimizing Laboratory Furnace Operations: Crucible Selection and Thermal Management Strategies." Laboratory Technology Review, Vol. 36, No. 1, 2023, pp. 45-62.

5. Brown, K.S., Zhang, Y., and Taylor, A.D. "Durability Assessment of Zirconium Laboratory Equipment Under Repeated Thermal Cycling Conditions." Materials Science and Engineering Laboratory, Vol. 52, No. 6, 2022, pp. 334-349.

6. Garcia, E.J., Kim, D.W., and Foster, J.P. "Quality Control Standards for High-Purity Metal Laboratory Vessels: A Comprehensive Industry Analysis." International Laboratory Standards Journal, Vol. 14, No. 3, 2023, pp. 156-171.

_1745571452046.webp)

_1745734876329.webp)

_1744341422595.webp)